Method of spinning yarn in spindleless spinning machine including fiber collecting surface as well as apparatus for making the same

A spinning machine, yarn technology, applied in the field of devices implementing the method, capable of solving the problems of speed ratio difference, yarn volume loss, reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

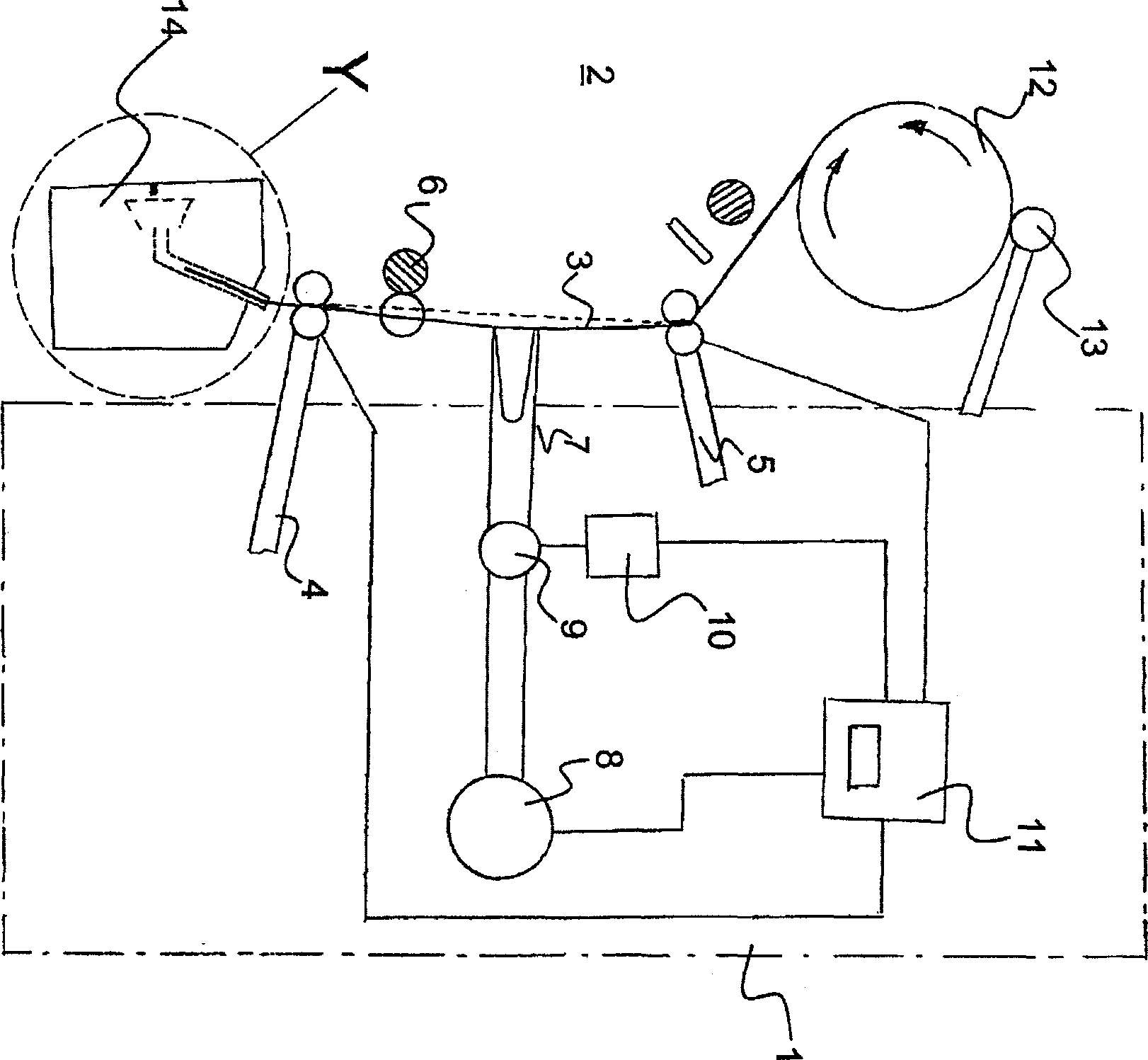

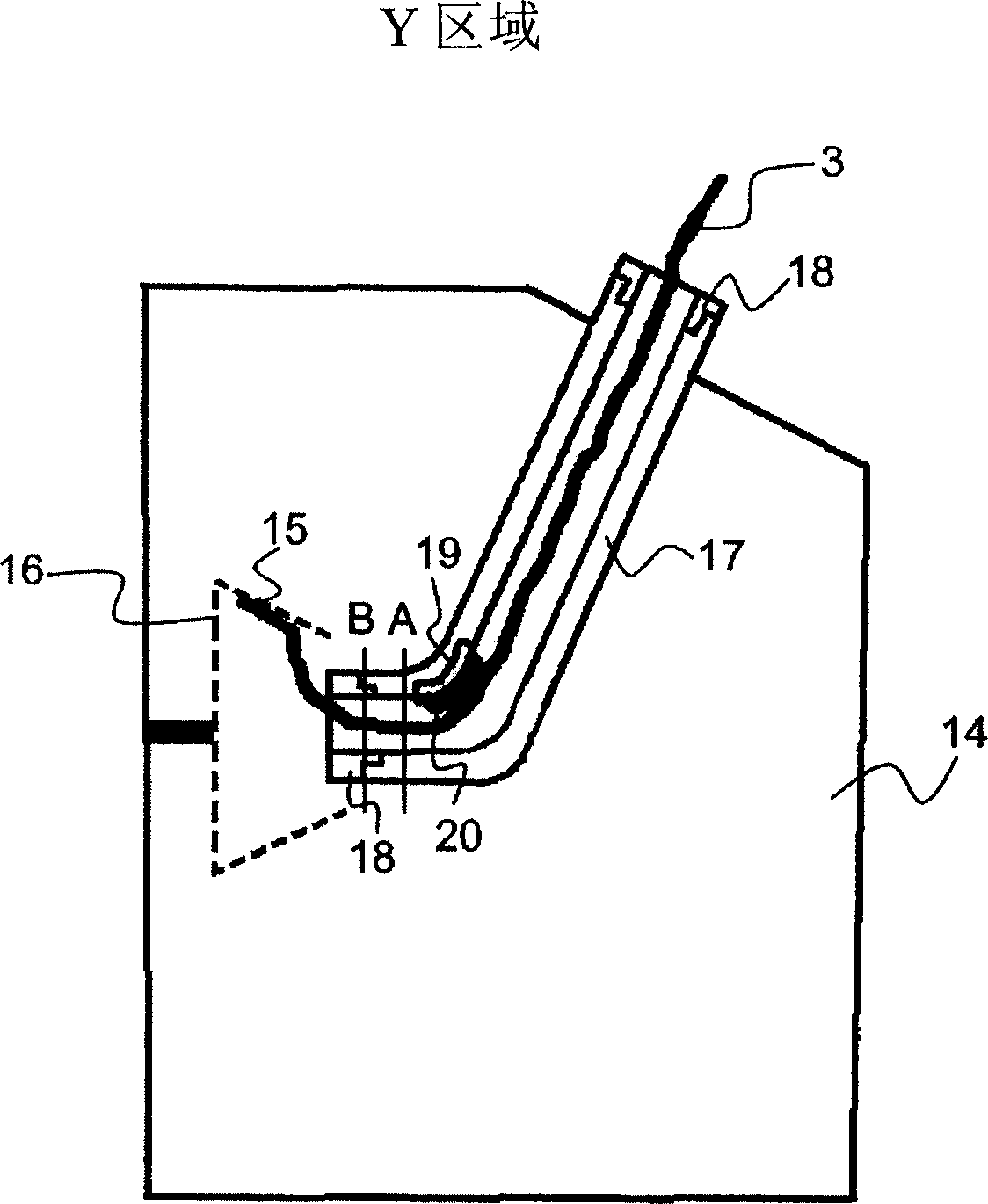

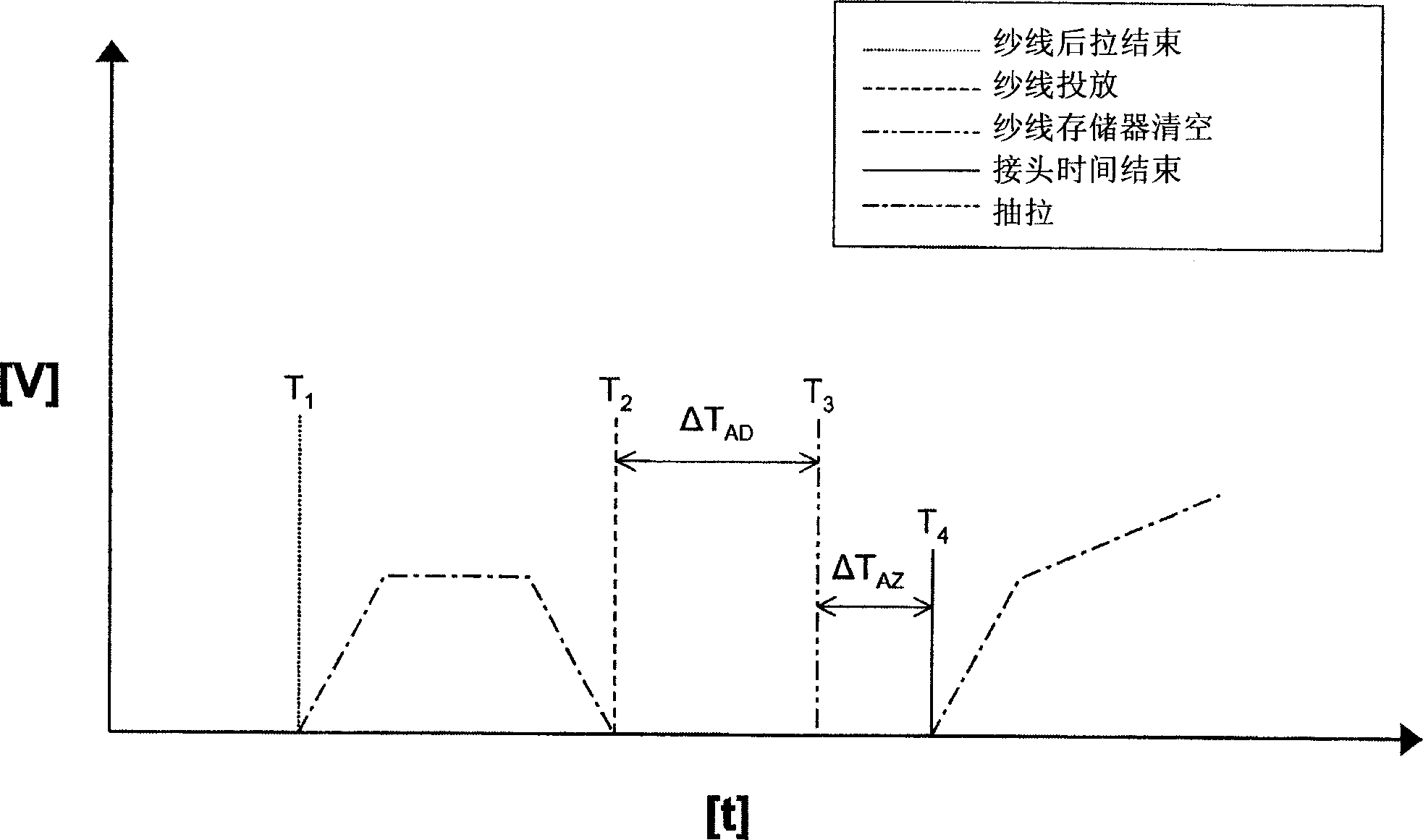

[0024] figure 1 A maintenance device 1 is schematically shown in . The maintenance device 1 is located in front of an open-ended spinning machine 2 which is only partially shown. The maintenance device 1 has a first pair of auxiliary rollers 4 and a second pair of auxiliary rollers 5 for gripping the yarn 3 . Between the first and second auxiliary roll pair 4 , 5 is a main roll pair 6 , which belongs to the open-end spinning frame 2 . A yarn storage device 7 is also arranged between the two auxiliary roller pairs 4,5. The shown yarn storage device 7 consists of a vacuum source 8 , a valve 9 and a servo drive 10 . Both the vacuum source 8 and the servo drive 10 are connected to a control device 11 and are regulated by it. Also connected to the control device 11 are the above-mentioned two pairs of auxiliary rollers 4 and 5 . In the shown state, the bobbin 12 on which the yarn 3 is wound on the open-end spinning machine 2 is driven by an auxiliary drive mechanism 13 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com