Centrifugal multi-blade fan

A multi-blade, centrifugal technology, used in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as blade deformation, insufficient strength, deformation of auxiliary blades 101, etc. , to achieve the effect of preventing deformation, improving air transport capacity and noise suppression performance, and improving air transport capacity and noise suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

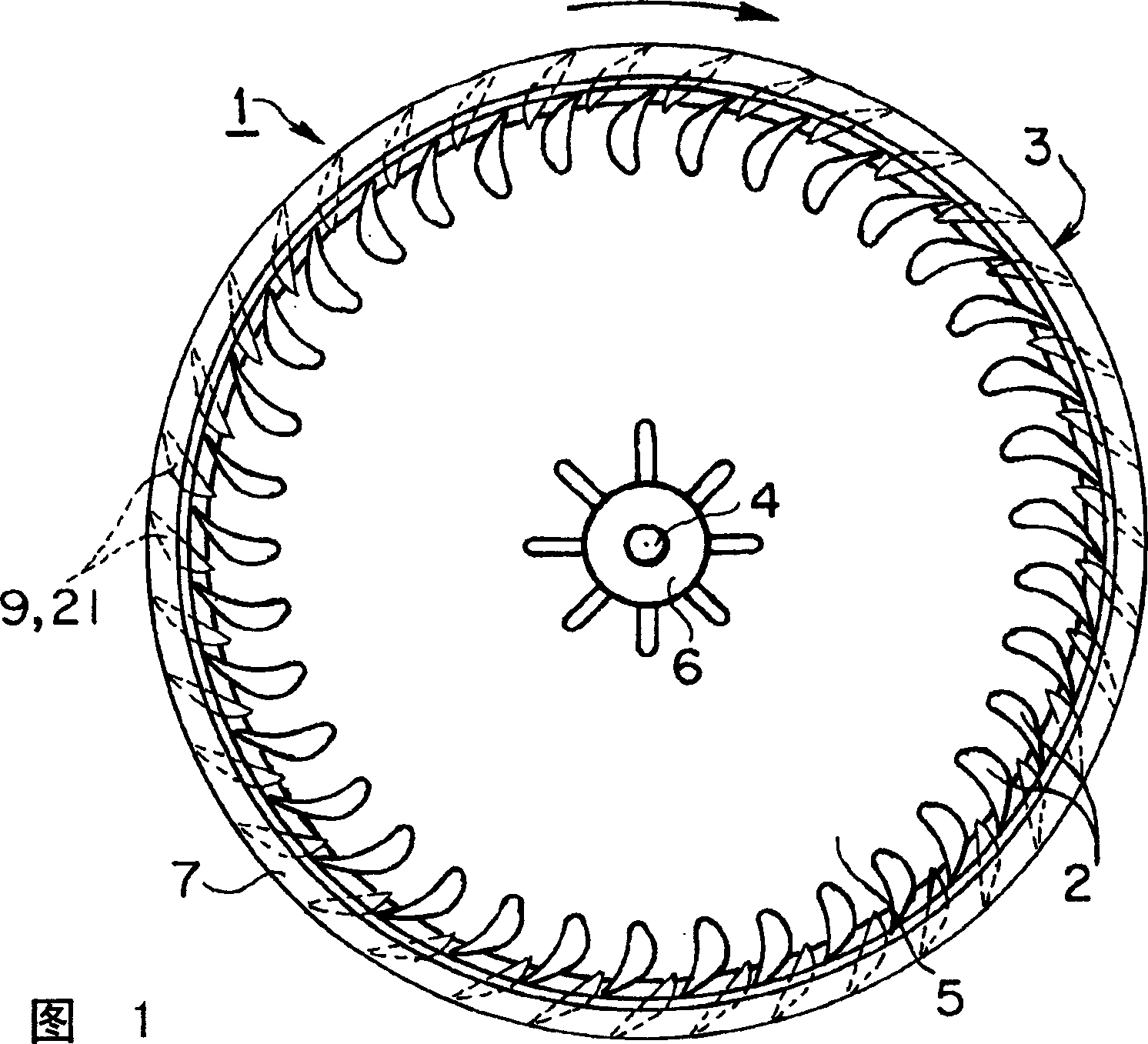

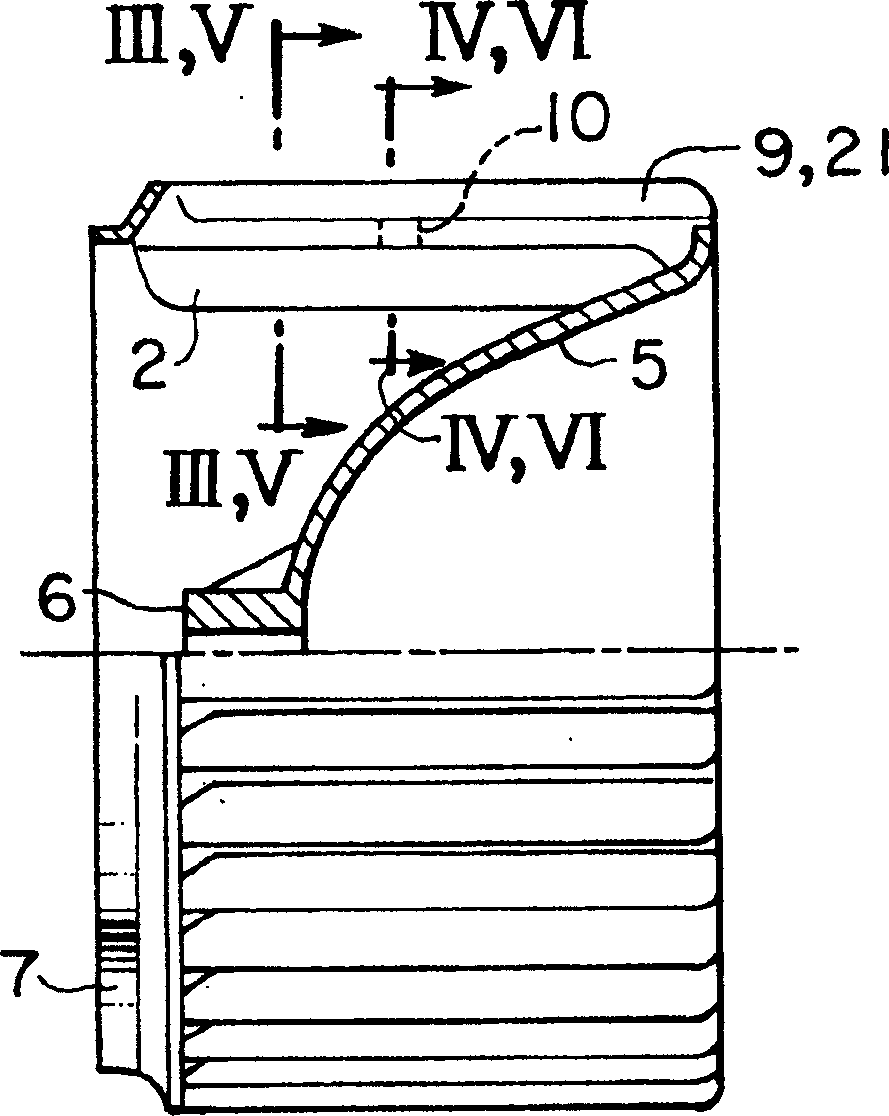

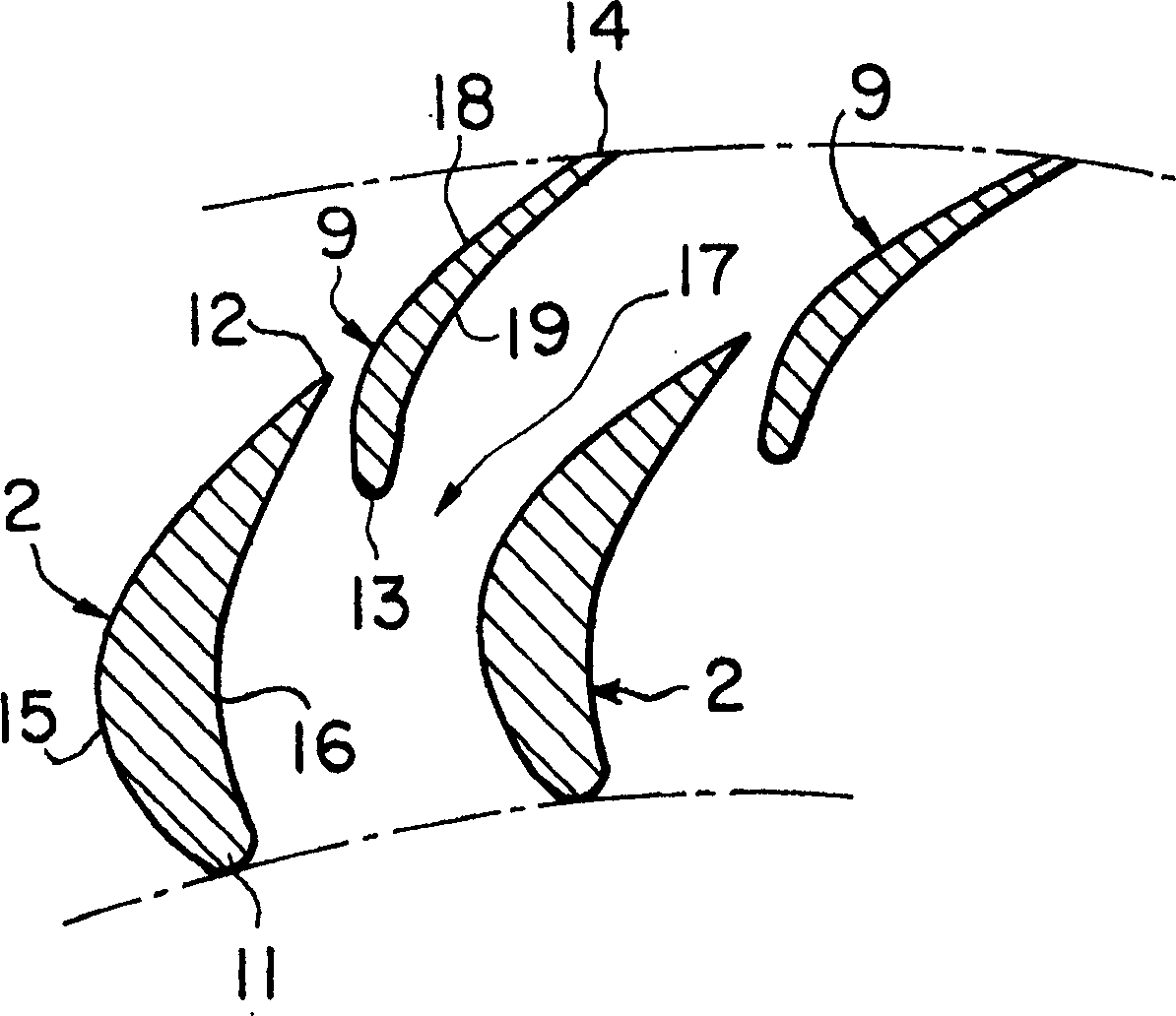

[0028] Figure 1 to Figure 4Shows a centrifugal multi-blade fan according to the first embodiment of the present invention. Among them, Figure 1 and figure 2 It is generally used to explain the second embodiment of the present invention described later. In Figure 1 and figure 2 Among them, the multi-blade fan part 3 of the multi-blade fan 1 has a plurality of main blades 2 and a plurality of auxiliary blades 9 . A plurality of blades 2 and 9 are arranged in a circumferential direction around the rotating shaft 4 . A disk-shaped drive plate 5 is arranged on the first ends of the blades 2 and 9 (on the anti-suction side of the fan 1 ) and is connected to all the blades 2 and 9 . A boss 6 is formed at a central portion of the drive plate 5 . The rotating shaft 4 is packed into the shaft sleeve 6, and by the rotation of the rotating shaft 5, the driving plate 5 and all the blades 2 and 9 rotate in a predetermined direction (the direction indicated by the arrow in FIG. 1). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com