Lithium silicon compound radio-frequency wall processing technology capable of used in nuclear fusion experimental device

A technology of experimental equipment and processing technology, applied in thermonuclear fusion reactors, nuclear engineering, fusion reactors, etc., can solve problems such as difficulty in forming dense and high-quality coatings, inability to meet high-power, long-pulse physical experiments of fusion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

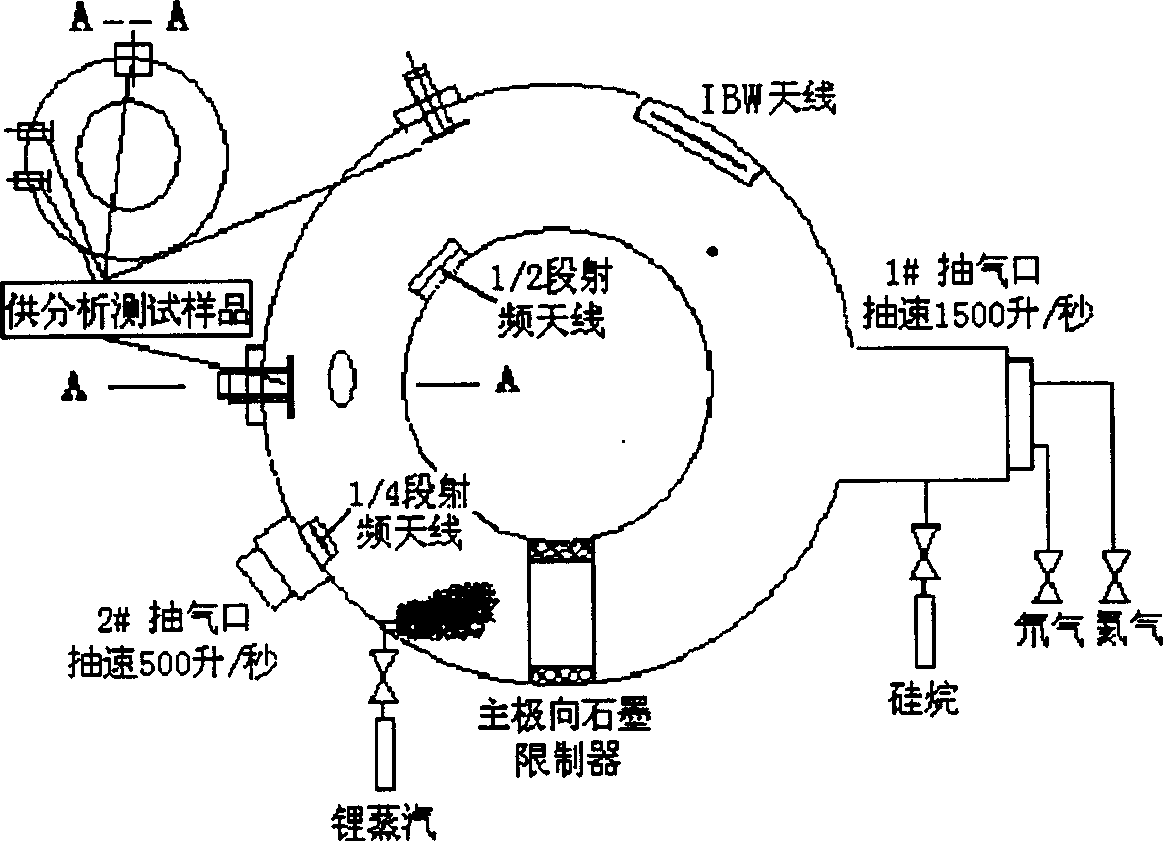

Image

Examples

Embodiment Construction

[0012] Before and after the lithium-silicon radio frequency composite wall treatment, sufficient ion swirl wall cleaning is required. One is to remove as much as possible the impurities adsorbed on the wall before the wall treatment; the other is to remove most of the hydrogen contained in the coating after the wall treatment.

[0013] Due to the strong chemical reactivity of lithium, it can react with the residual gas CO, CO in the ultra-high vacuum tokamak device at room temperature. 2 、H 2 , O 2 、CH 4 and H 2 O reacts chemically with the metal oxides on the wall. Therefore, before the in-situ radio frequency lithium-silicon composite wall treatment, the first wall needs to be fully cleaned by ion swirling walls to remove these impurities as much as possible; After the wall is cleaned, 10% silane and 90% helium need to be introduced, and after 10-20 minutes of radio frequency silicide, lithium vapor is sent into the tokamak tangentially (changed from the original radial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com