Modular sheet-fed rotary printing press

A technology of machine and storage unit, which is applied in the direction of rotary printing machine, printing machine, printing, etc., and can solve the problem of not giving instructions for driving and controlling each basic module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

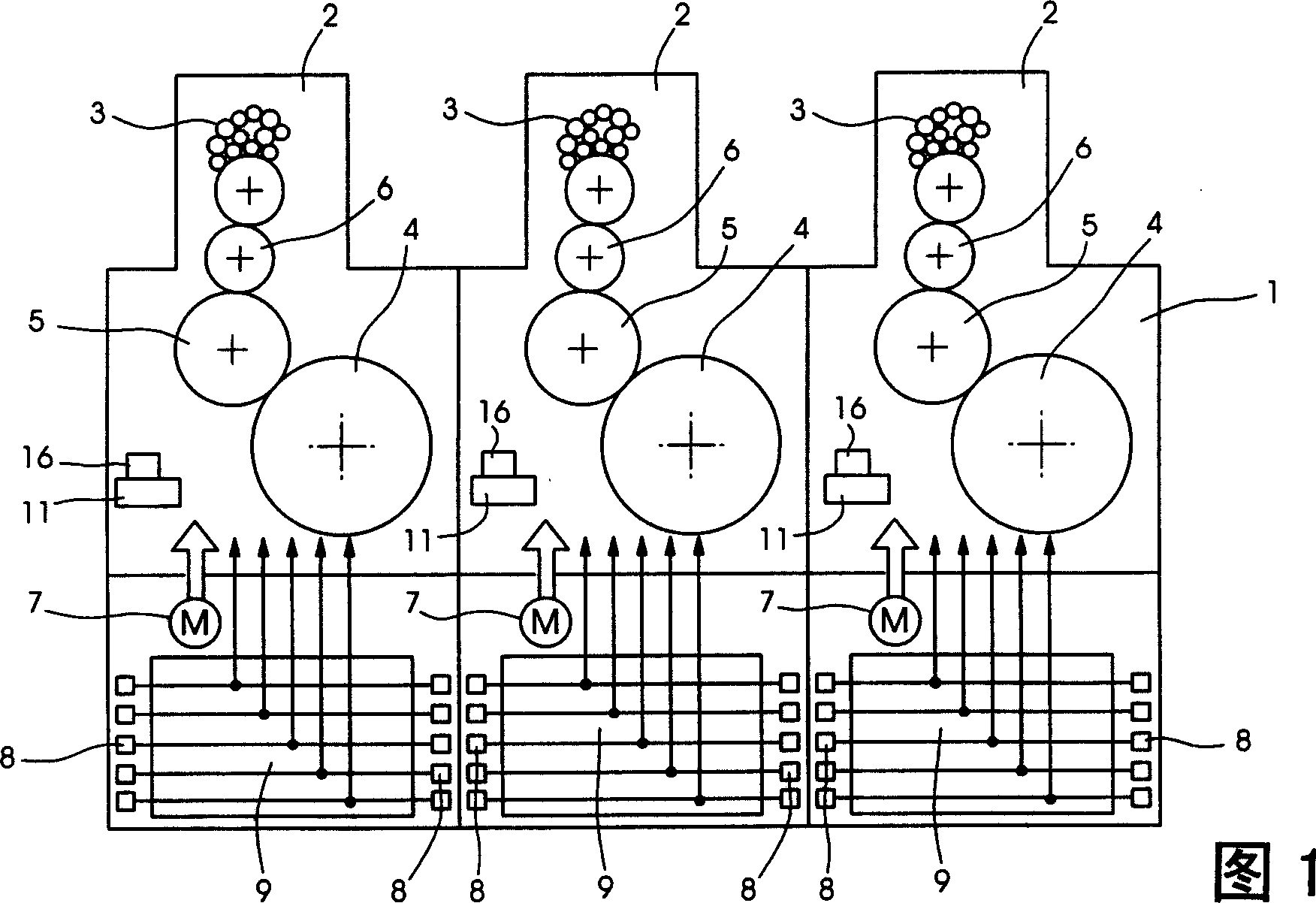

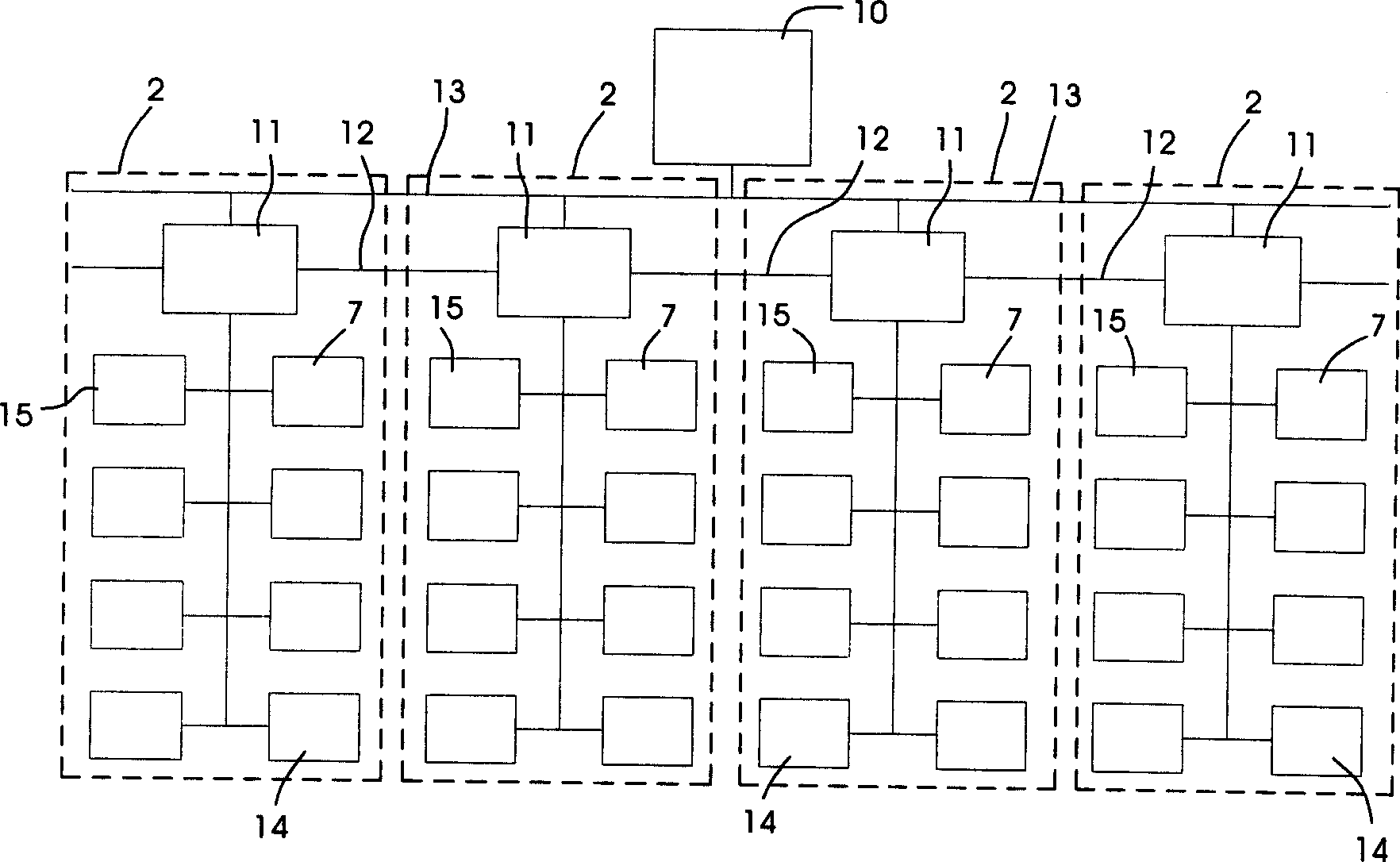

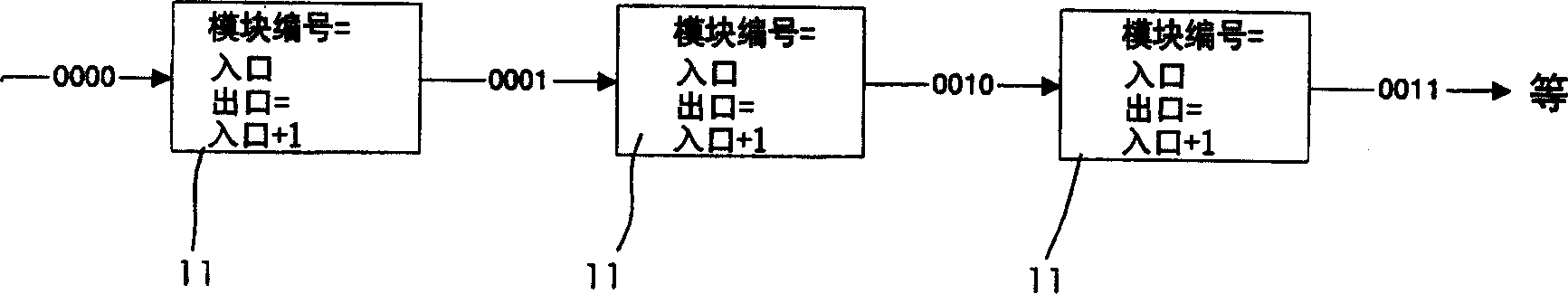

[0026] FIG. 1 shows a modular printing press 1 which consists of three printing units 2 , ie modules. In this case the modules 2 shown in FIG. 1 are of identical design, but this is not absolutely necessary. It is only important that the modules 2 have mutually compatible interface areas. Each modular printing unit 2 has an inking unit 3 , which in each case applies printing ink to a printing form cylinder 6 . The printing plate cylinder 6 is operatively connected to a blanket cylinder 5 which prints on a single printing material applied to the transport cylinder 4 . Each printing unit 2 is thus a self-sufficient module which, if necessary, can also be operated as a single monochrome printing press 1 . Furthermore, the modules 2 each have a drive motor 7 which either drives all the rollers and other rotating components of a module 2 or is supported by electrical auxiliary mechanisms. These auxiliary mechanisms can, for example, drive the inking unit 3 individually. Finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com