Backlight assembly

A technology of backlight components and backplanes, which is applied in the directions of optics, diffusion elements, nonlinear optics, etc., and can solve problems such as time-consuming, labor-intensive, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

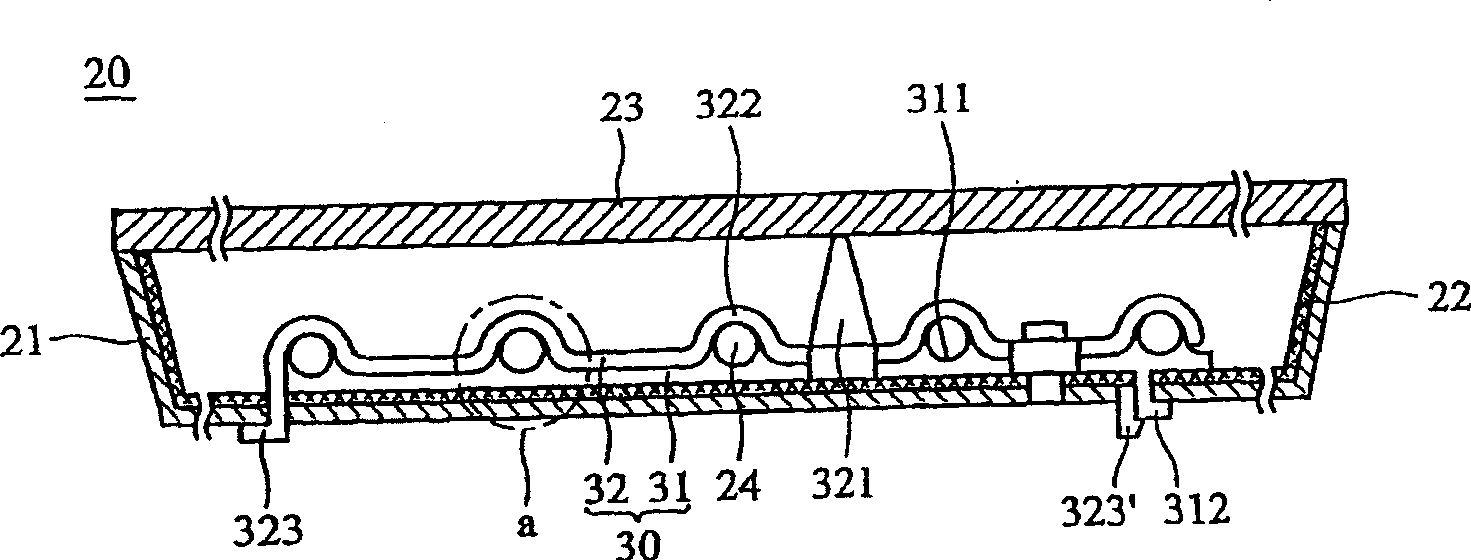

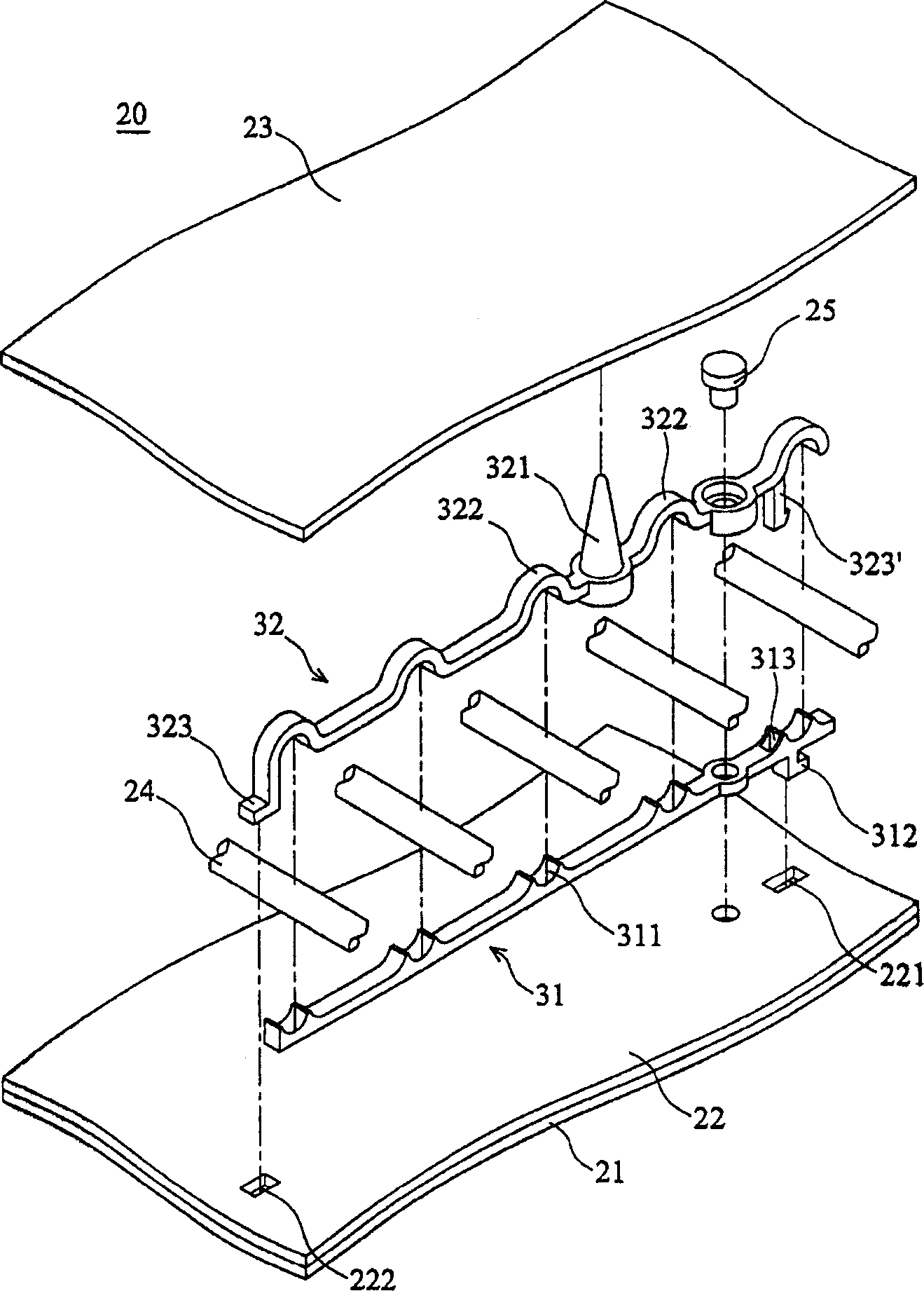

[0040] The direct type backlight assembly of a preferred embodiment of the present invention is as follows figure 2 Shown, where, in order to simplify the diagram, figure 2 Only an improved support structure and five lamp tubes are shown, but the actual application is not limited thereto.

[0041] The direct type backlight assembly 20 of the present invention includes a backplane 21 , a reflection sheet 22 , a diffusion plate 23 , a plurality of lamp tubes 24 and a support member 30 . The surface of the back plate 21 is provided with a plurality of reflective sheets 22 for reflecting light; the diffuser plate 23 is installed on the back plate 21 to form an enclosed space; the support member 30 is arranged between the reflective sheet 22 and the diffuser plate 23, including a The base 31 and a fixing part 32 are clamped by the base 31 and the fixing part 32 , and are arranged at intervals between the reflection sheet 22 and the diffuser plate 23 , serving as light sources of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com