Connecting structure for rod

A technology of connecting structure and ground connection, which can be used in the connection of rods, connecting members, cleaning carpets, etc., and can solve problems such as gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

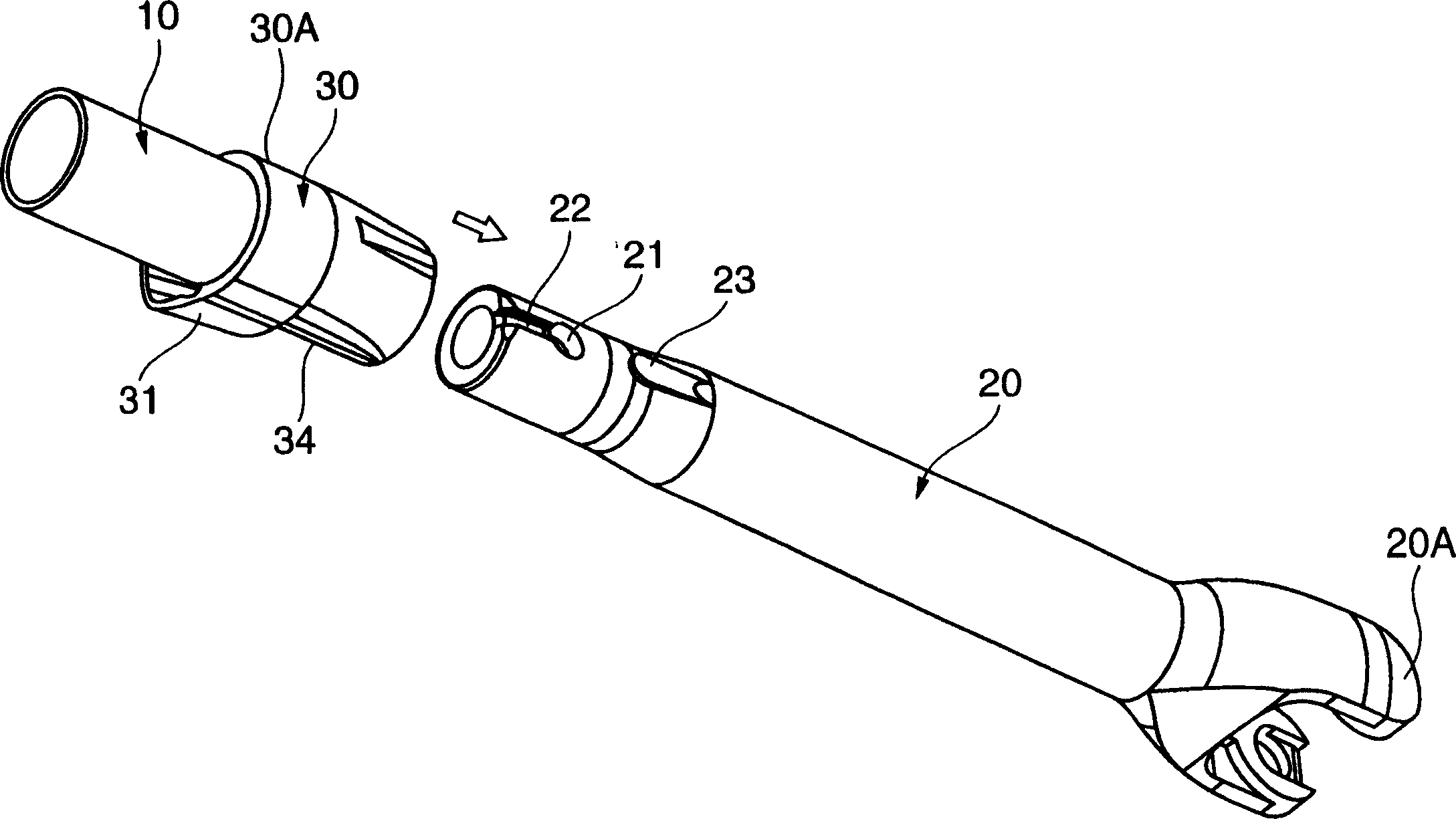

[0019] figure 1 It shows that the first rod 10 and the second rod 20 constituting a part of the handle of the cleaning tool are inserted into each other and connected male and female by the connecting tool 30 provided on the first rod 10 . Moreover, the 2nd lever 20 is equipped with 20 A of cleaning head attachment parts as a front-end|tip part which comprises a handle.

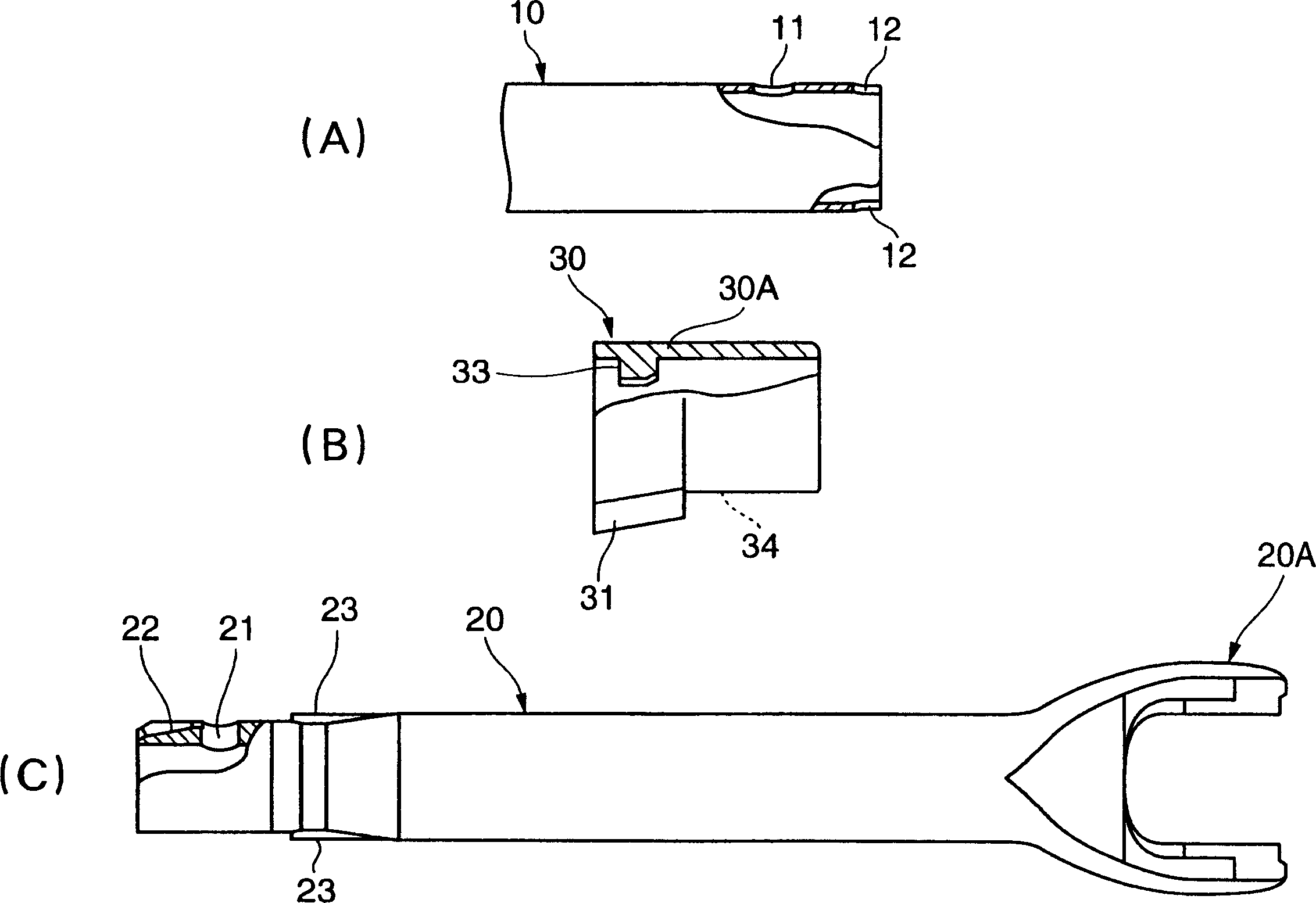

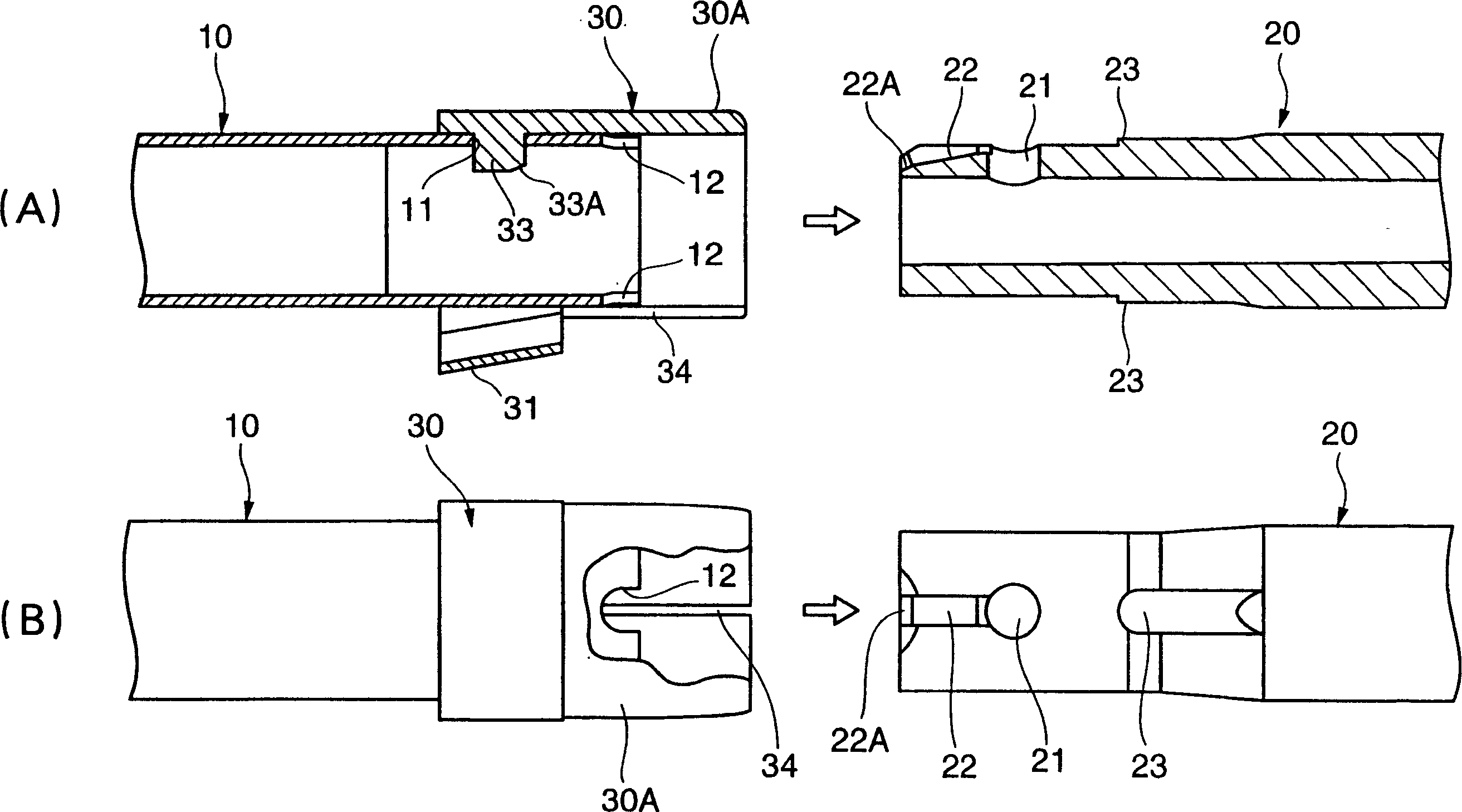

[0020] The first rod 10 is made of pipe material, such as figure 2 As shown in A, on the peripheral wall of one end of the pipe material, there are mounting holes 11 for connecting the tool 30 penetratingly. Two positions at 100° intervals, or a single position) is provided with a notch 12 for anti-rotation. The anti-rotation notch 12 is formed in a U-shape opening outward in the axial direction.

[0021] The connecting tool 30 installed on the first bar 10, such as figure 2 As shown in (B), it is substantially linear in its entirety (straight portion 30A), and is constituted by a short cylindrical memb...

Embodiment 2

[0037] Figure 8 It shows that the first rod 110 and the second rod 120 constituting a part of the handle of the cleaning tool are inserted into each other through the connecting tool 130 attached to the first rod 110, and the male and female are fitted and connected.

[0038] The first rod 110 is made of a pipe, and has an annular mounting groove 111A and a mounting hole 111B for connecting the tool 130 on the peripheral wall of one end of the pipe. Strip-shaped anti-rotation ribs 112 .

[0039] The connecting tool 130 mounted on the first rod 110 is composed of a C-shaped fixing ring 131 and an arc-shaped operating ring 132, wherein the fixing ring 131 is formed at a half circumference larger than the mounting groove 111A of the first rod 110. Within the range, the operating ring 132 is coupled to both ends of the fixing ring 131 by pins so that it can be embraced almost without gap by the habit of ejecting the reduced diameter. In the state where the connection tool 130 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com