Methods for controlling screenouts

A filter screen and filter cake technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve problems such as uncertainty of the terminal screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Table 1

[0071] Working parameters

no fiber

half-length of the supported fissure

(feet)

101.1

77.1

The width of the wellbore being supported (in

Inch)

0.348

0.497

average supported width

0.235

0.375

Net pressure at the end of the job

649

1033

efficiency

0.509

0.533

Effective Conductivity (mD-ft)

1256

1947

[0072] Table 2

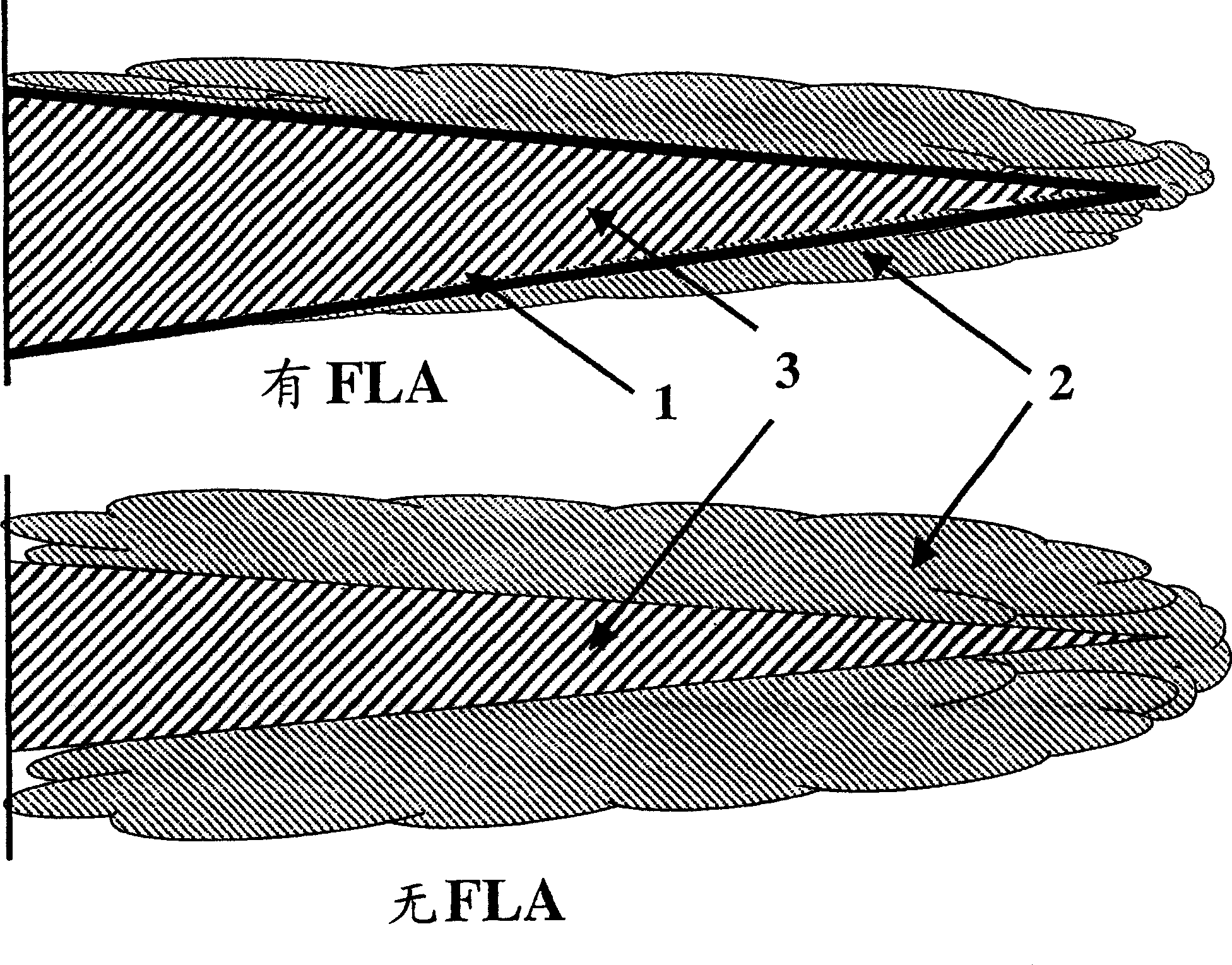

[0073] It can be seen that by adding fibers, the slit is shorter, wider and more conductive. By employing fibers, fluid efficiency is increased, which reflects the amount of proppant placed with a given amount of carrier fluid. If there is no fiber, then at 99 feet proppant is packed after 15 barrels of stage 6 have been pumped. Proppant is packed at 76 feet, if fiber, after 22 barrels of stage 4 have been pumped.

Embodiment 2

[0075] parameters

[0076] table 3

[0077] to run

[0078] Table 4

Embodiment 3

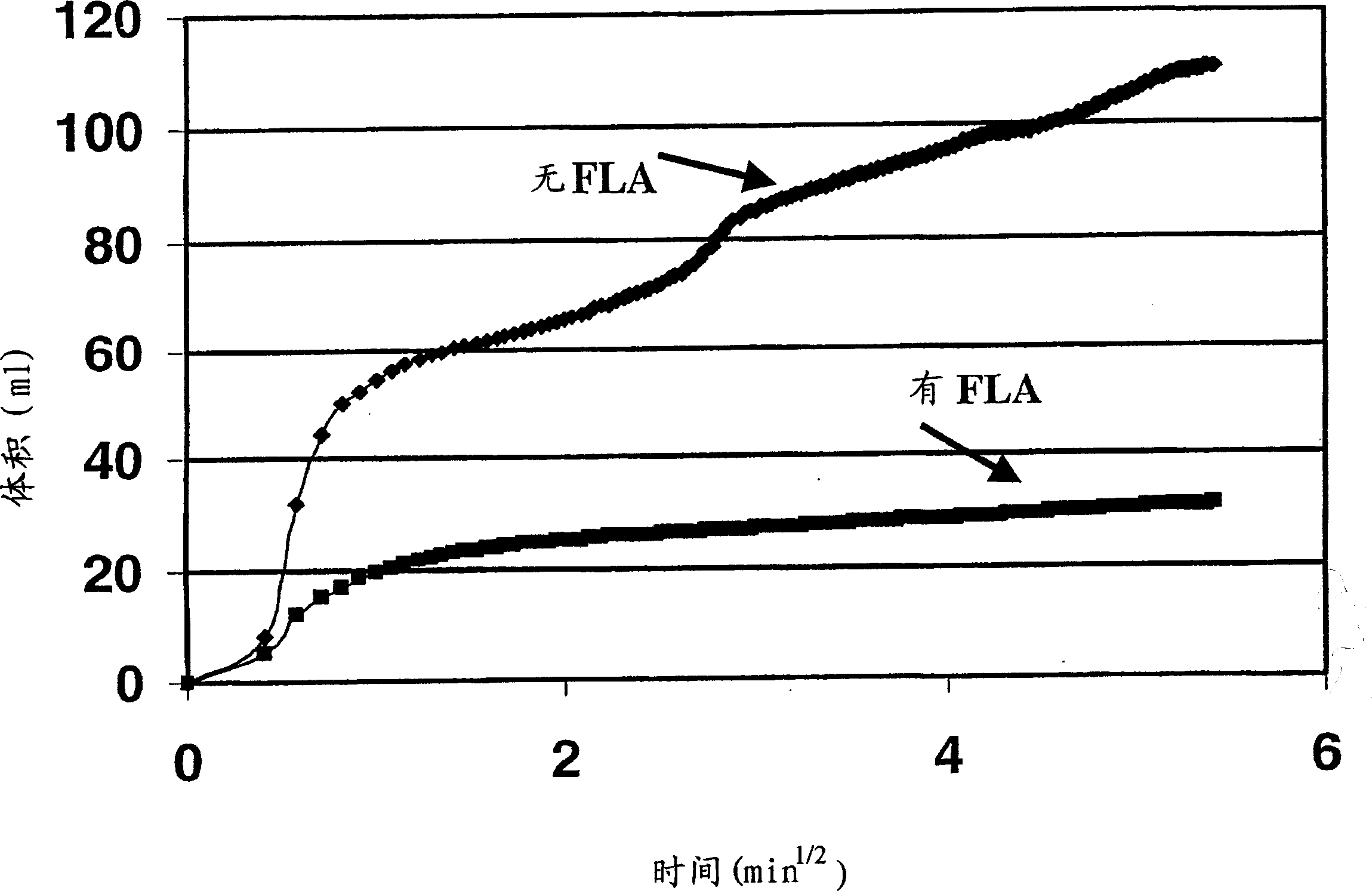

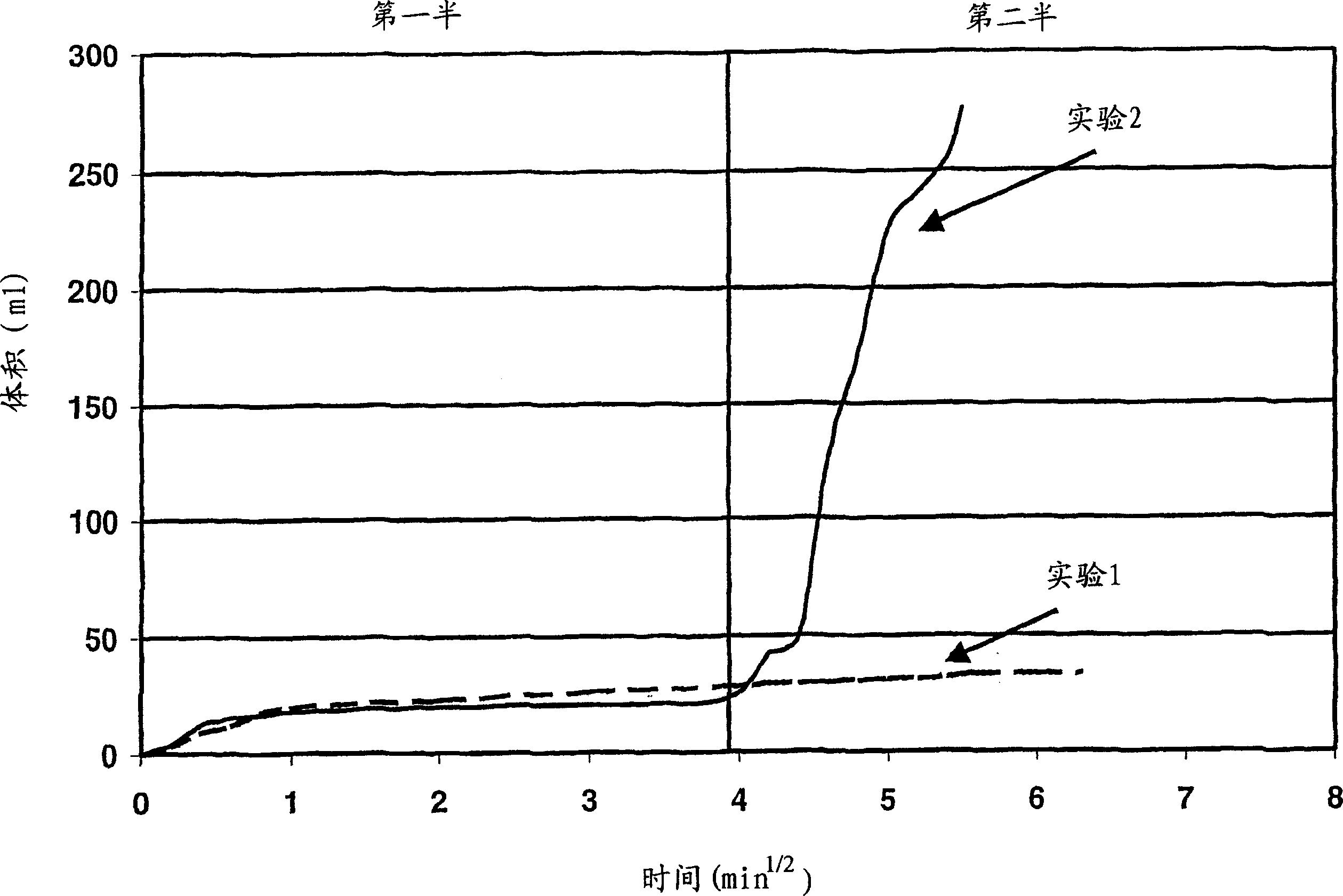

[0080] image 3 Some laboratory experiments are shown to illustrate the method of the present invention utilizing two fluid loss control additive cracker (cake degrader) stages. These are fluid loss experiments using the same method as in Example 1 at 52°C. It can be seen that in Experiment 1, when the first half contained the fluid loss control additive, the first splitting agent, and the splitting agent adjuvant (filter cake degrader adjuvant) for the second splitting agent present in the second half While still having the fluid loss control additive in the second half, there was no increase in fluid loss in the second half. In Experiment 2, when the first half was the same as in Experiment 1, but the second half contained no fluid loss control additive, the amount of fluid loss was significantly increased in the second half, indicating that the filter cake had been Serious destruction. In fracturing, this translates into bridging and / or reduced fluid efficiency and end s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com