Ground mobile working platform for electronic device

A technology of electronic equipment and workbench, which is applied in the direction of electrical components, electrical components, and the use of reradiation, etc., can solve the problems of large manpower consumption, machine crash and death, and leveling accuracy cannot be guaranteed, and achieve small size and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

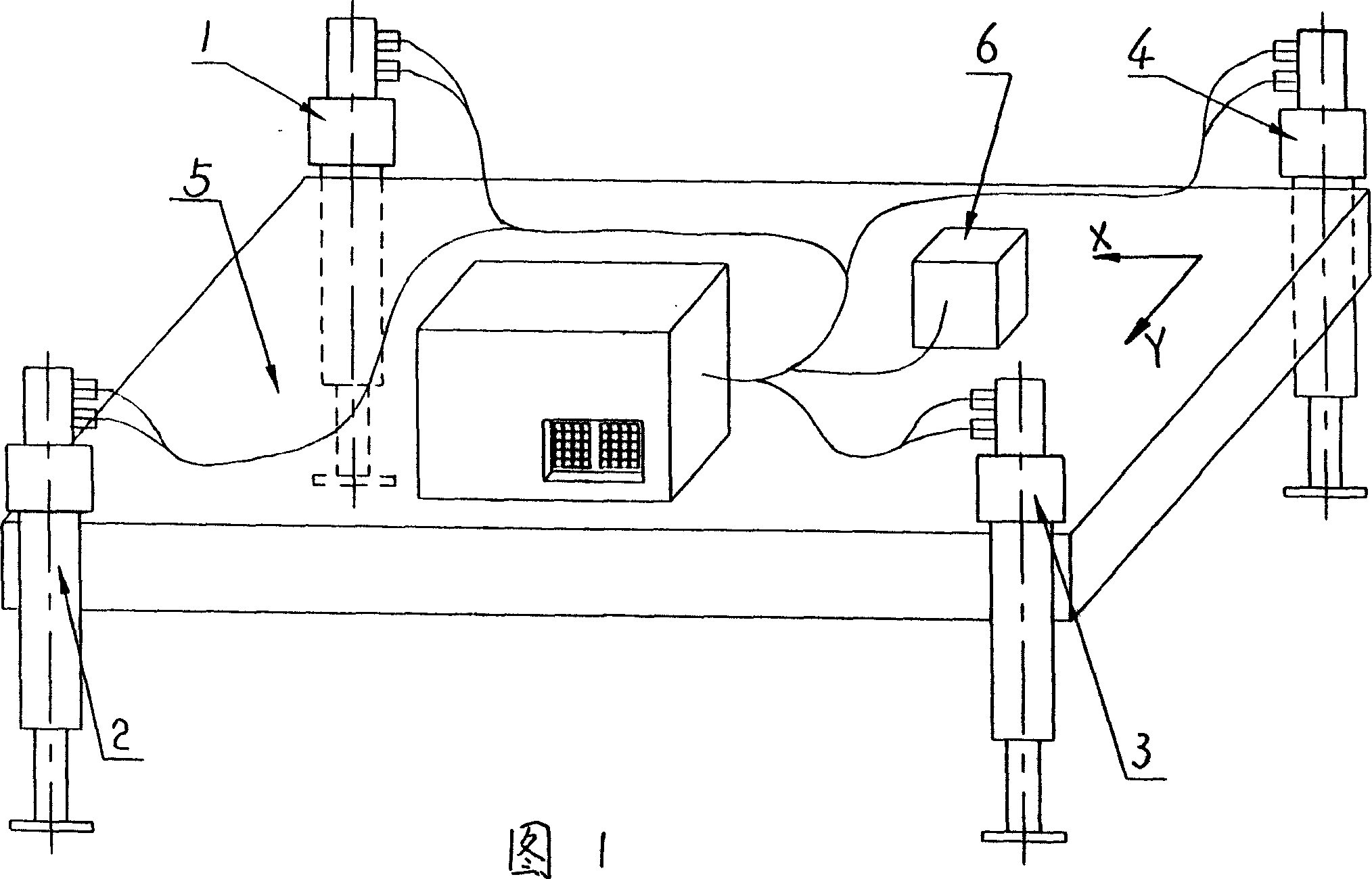

[0027] As shown in FIG. 1 , the ground motorized workbench for electronic equipment includes a workbench 5 , four leveling legs 1 , 2 , 3 , 4 and a level sensor 6 . The side of worktable surface 5 is connected with the shell sleeve bar 7 bolts of leveling support leg.

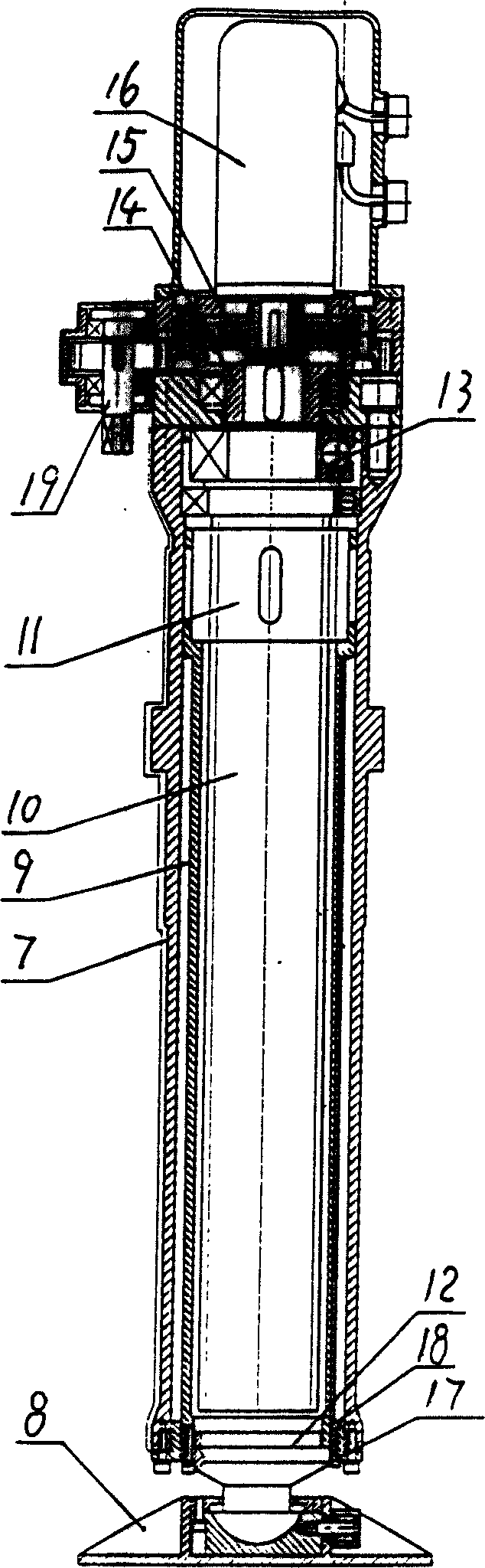

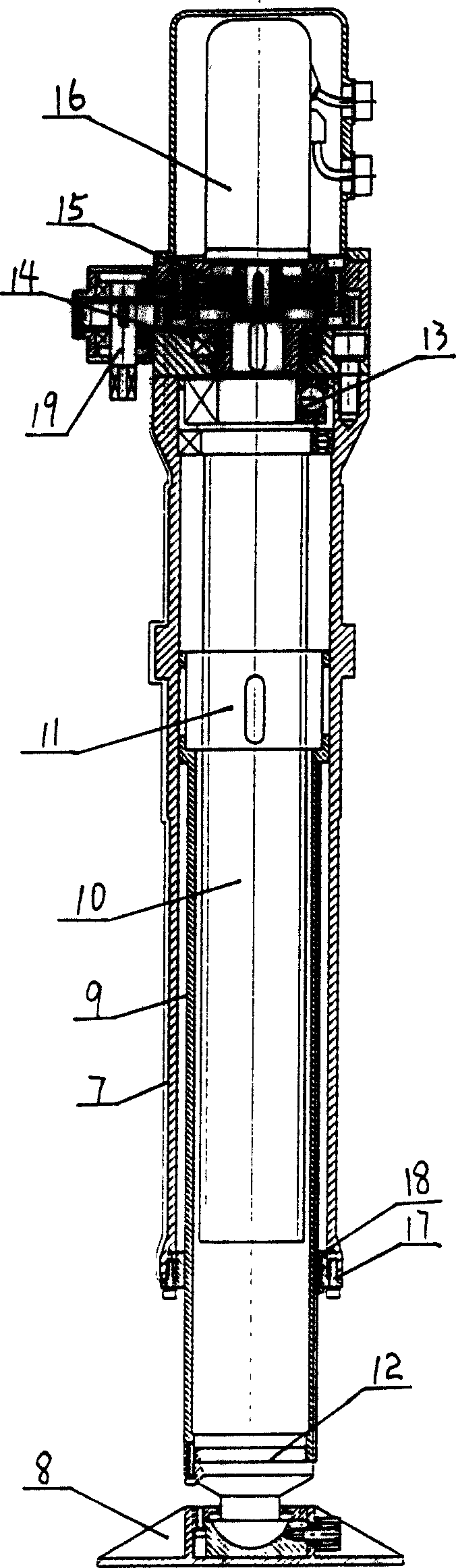

[0028] The leveling support leg comprises a base 8, a telescopic push rod mechanism and a driving mechanism.

[0029] There is a semi-spherical groove in the middle of the base 8; the telescopic push rod mechanism includes a push rod 9 and a casing rod 7 fitted thereon, the push rod 9 is a hollow rod, and the top of the push rod 9 is fixedly installed with a nut 11 that cooperates with the lead screw 10 , the bottom of the push rod 9 is equipped with a spherical hinge support 12 that matches the hemispherical groove of the base 8; , the shaft sleeve 17 is connected with the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com