Wheel rim squeezing formation for spinning flat pulley

An extrusion forming and flat pulley technology, which is applied in the field of flat pulley processing technology, can solve the problems that flat pulleys are not easy, affect normal use, cannot achieve smooth surface, etc., and achieve the effect of satisfying appearance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

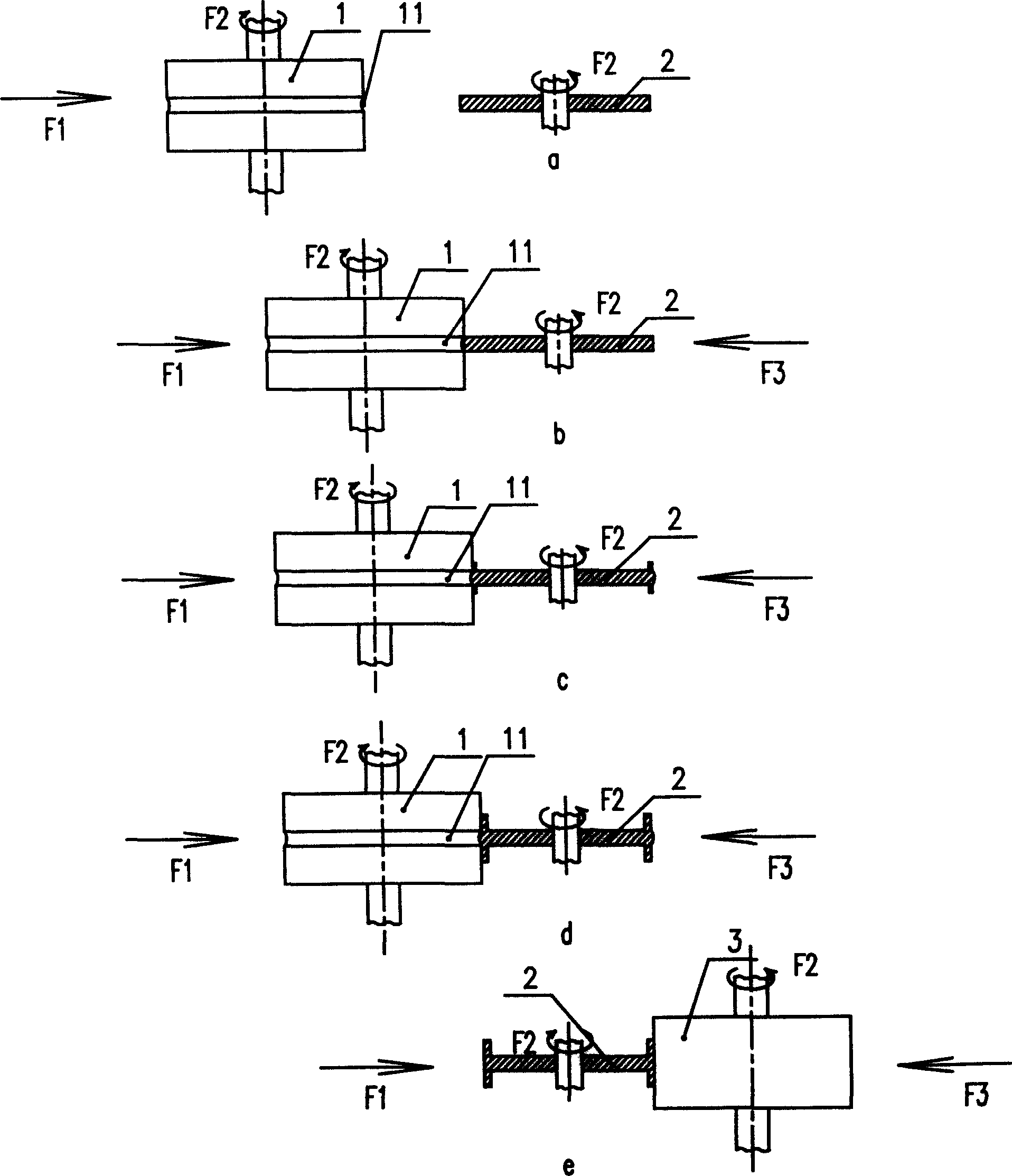

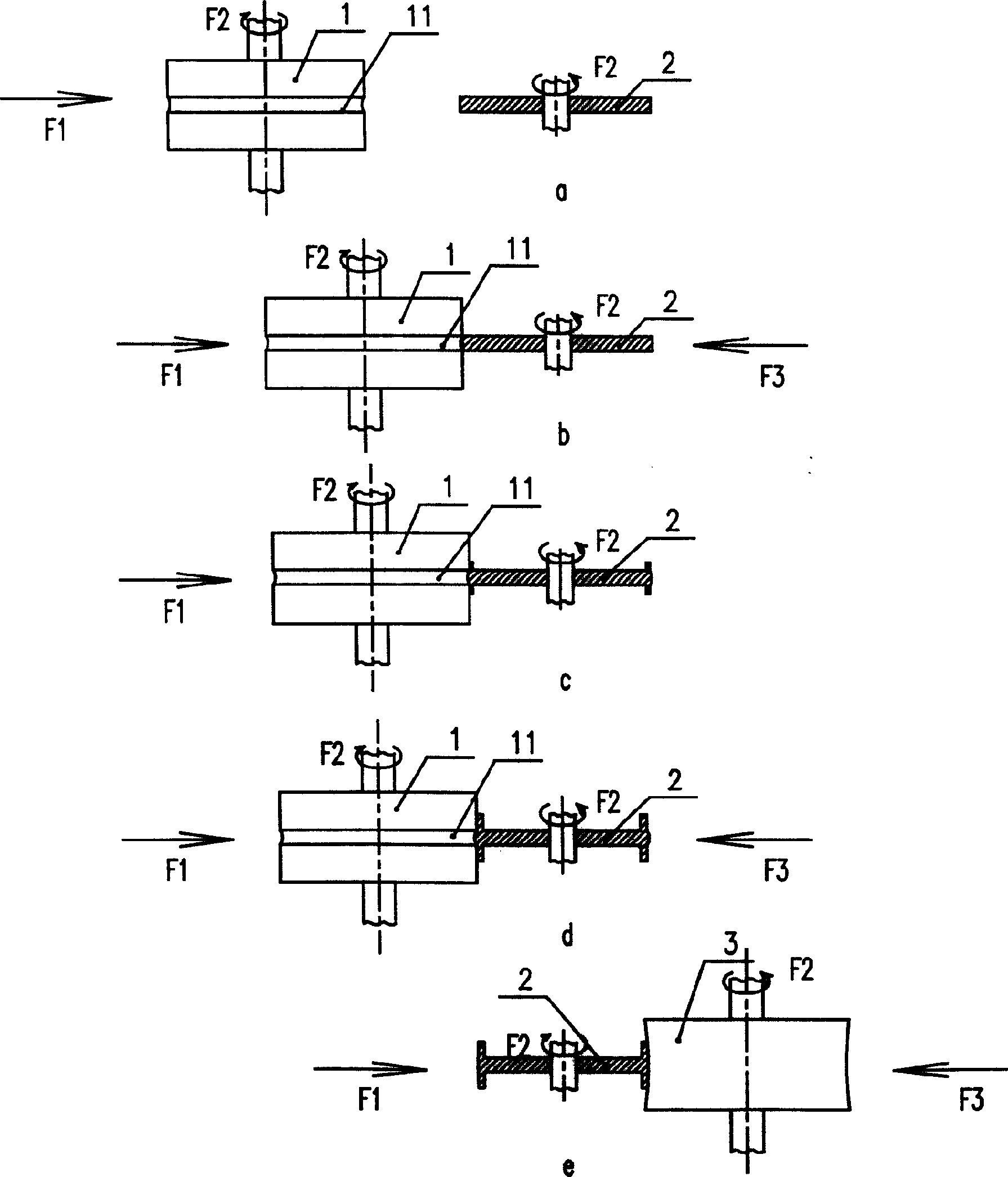

[0010] Such as figure 1 The first embodiment of the spinning flat pulley rim extrusion forming process shown in the present invention has the following steps: A. initial forming, such as figure 1 a. figure 1 b. figure 1 c. figure 1 As shown in d, the metal plate 2 and the forming die 1 with a bow-shaped groove 11 are respectively fixedly installed on the two rotating shafts of the machine tool, the machine tool starts to work, the metal plate 2 and the forming die 1 rotate in opposite directions, and the forming die is pushed 1. Make the forming die 1 move towards the metal plate 2, and the metal plate 2 pushes to the bottom of the bow-shaped groove 11. The metal plate 2 is subjected to the rotational force F2, and at the same time, the metal plate 2 is also subjected to the pressure F1 of the forming die 1, and generates a reaction force F3 , the metal plate 2 is under the action of F1, F2, F3, the metal on the edge of the metal plate 2 flows to both sides evenly along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com