Cleaning device for textile machines

A cleaning device and textile machinery technology, which is applied in textiles, textiles, papermaking, and auxiliary equipment for weaving. It can solve the problems of high cost and poor cleaning effect, and achieve the effect of reducing the height of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

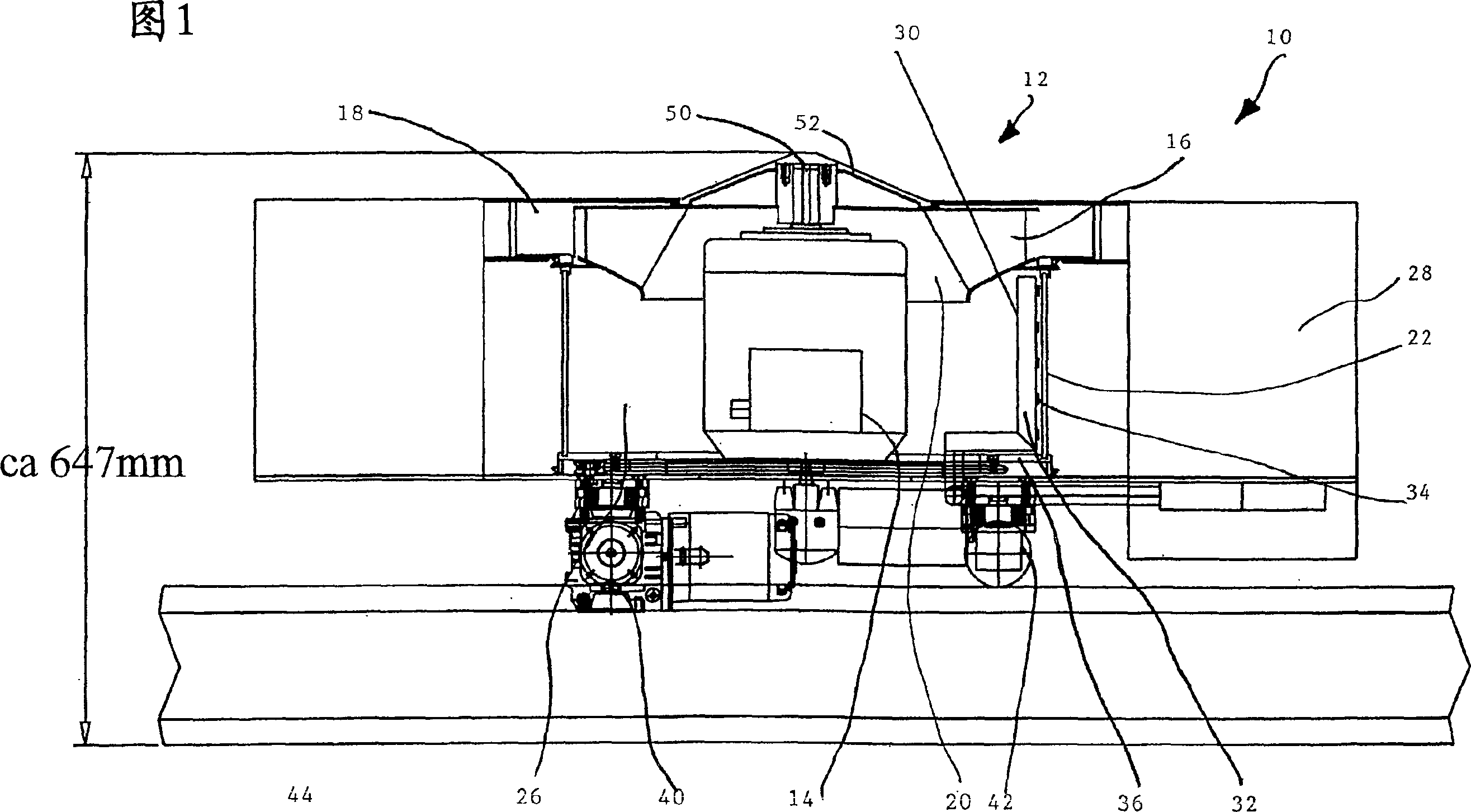

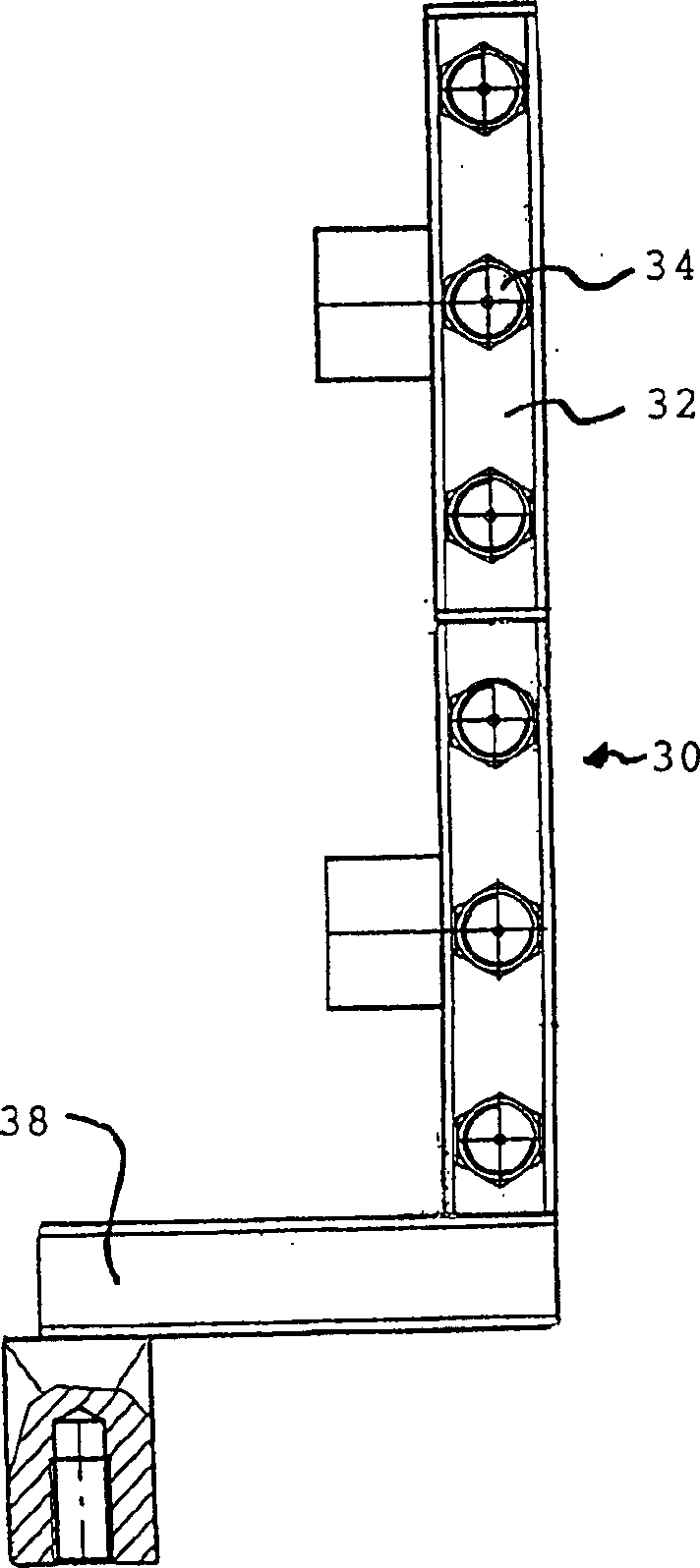

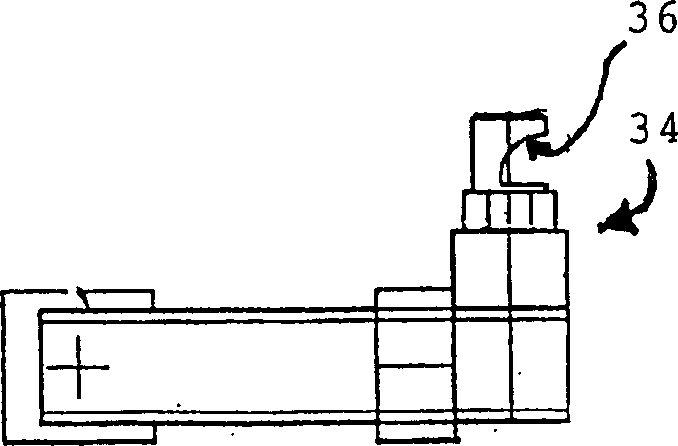

[0031] The cleaning device 10 shown in FIG. 1 comprises a trash remover 12 with a trash remover motor 14 which drives a trash remover wheel 16 . In known manner, a radial trash remover is provided. The trash trap is arranged in a known manner in a trash trap housing 18 . An axial inflow parallel to the motor is achieved by means of the axially oriented trash filter intake opening 20 , which has the effect of cooling the trash filter motor 14 in the cooling air flow.

[0032] The electric machine is surrounded by an annular filter 22 according to the invention almost over its entire height—in the exemplary embodiment shown approximately over 80% of its height. The diameter of the ring filter 22 is about 3 times the diameter of the motor in order to obtain sufficient internal free space for forming the suction chamber. The suction chamber 26 communicates in a known manner with the suction channel of the textile machine cleaning device, while a blowing chamber 28 also communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com