Hollow prefabricated steel bar reinforced concrete boards

A reinforced concrete slab and reinforced concrete technology, which is applied in the direction of building components, floor slabs, building structures, etc., can solve the problems of easy cracking of concrete, weak connection force at joints, and poor integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

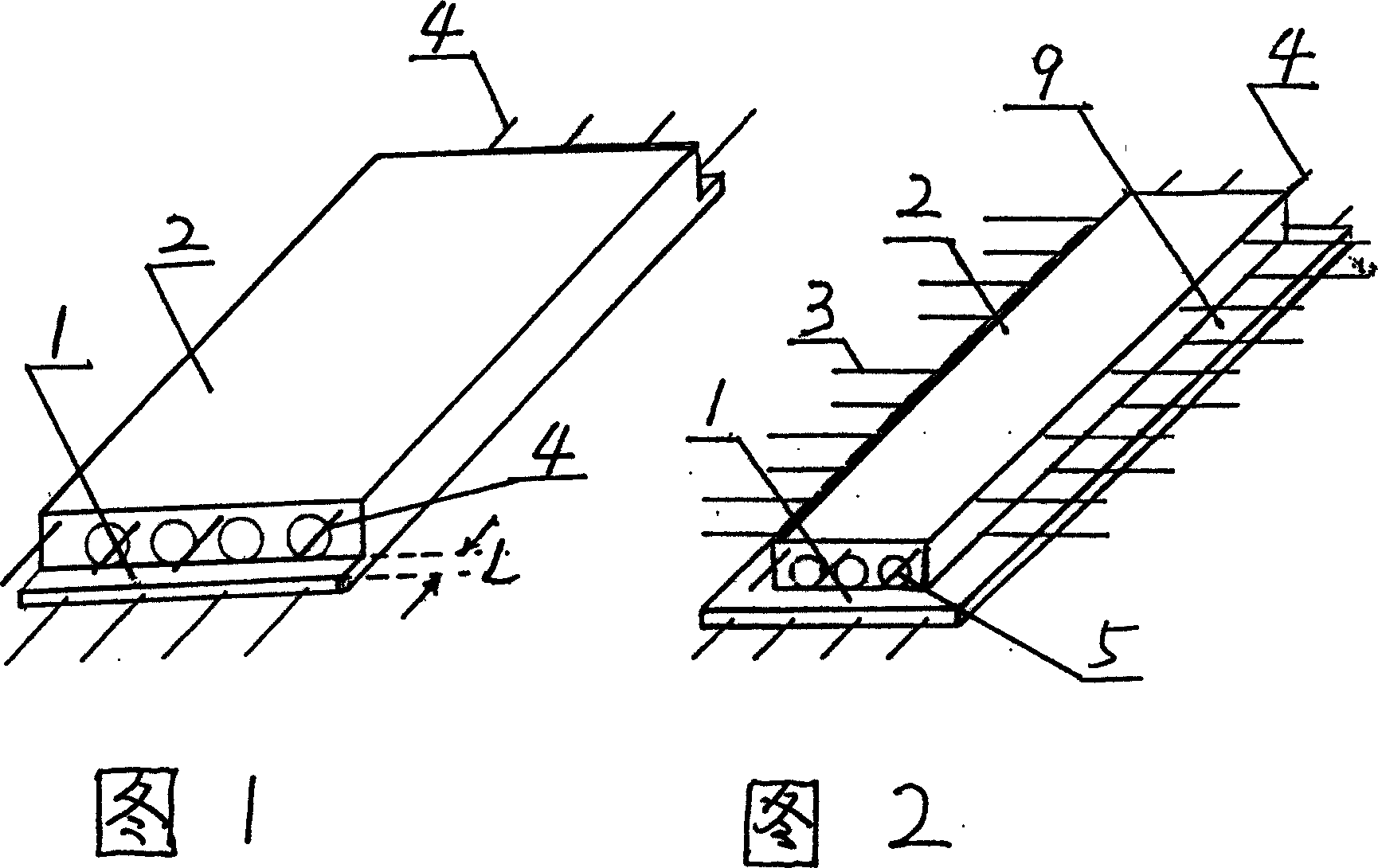

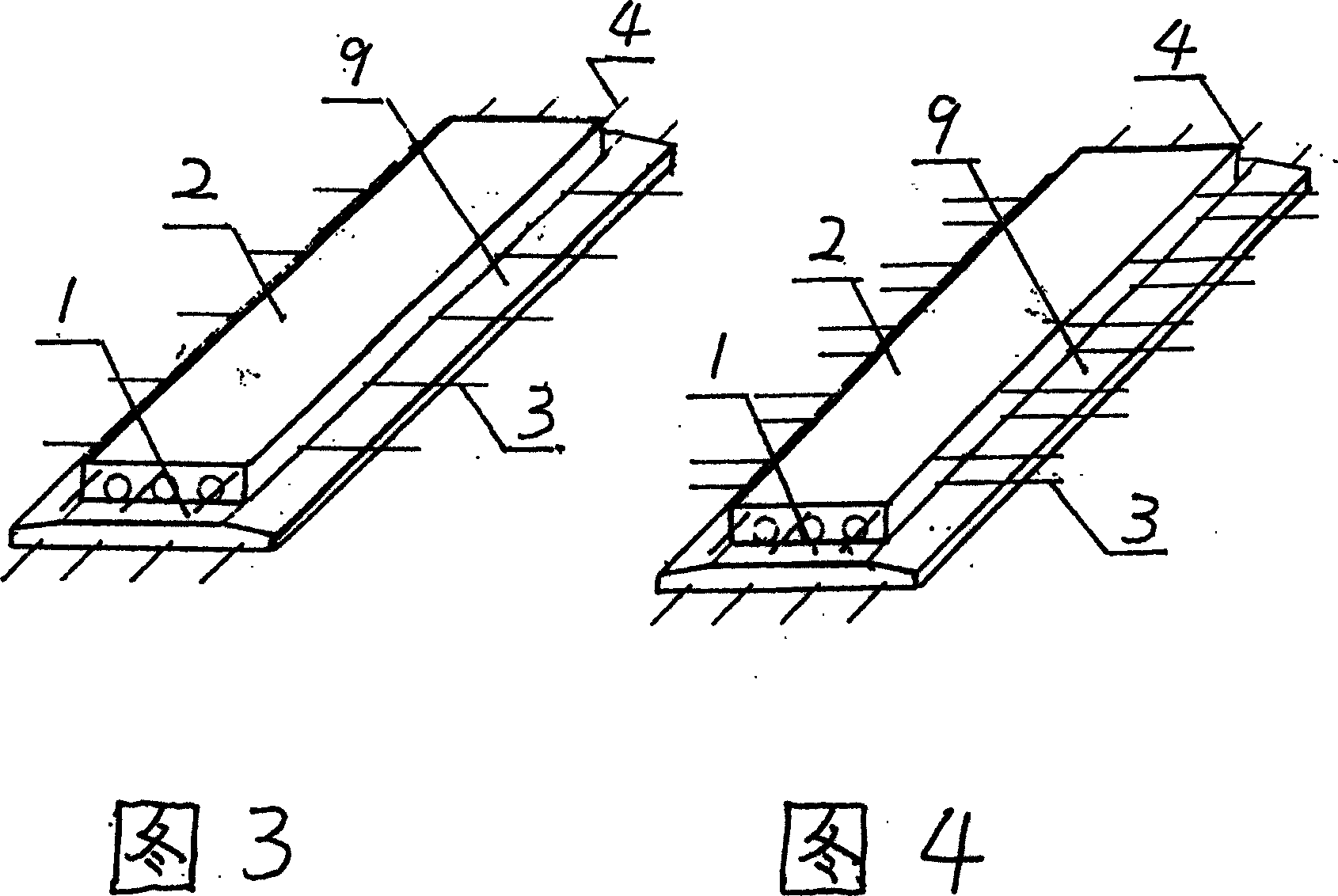

[0012] Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the reinforced concrete hollow prefabricated member panel includes a reinforced concrete panel body 2 with a through hole 5 in the middle, and the bottom of the reinforced concrete panel body 2 is provided with convex Out of the platform 1, the two ends of the reinforced concrete slab body 2 are provided with connecting steel bars 4, and the width L of the protruding platform 1 is greater than or equal to 2 cm. Both sides of the concrete slab body 2 are provided with connecting steel bars 3 .

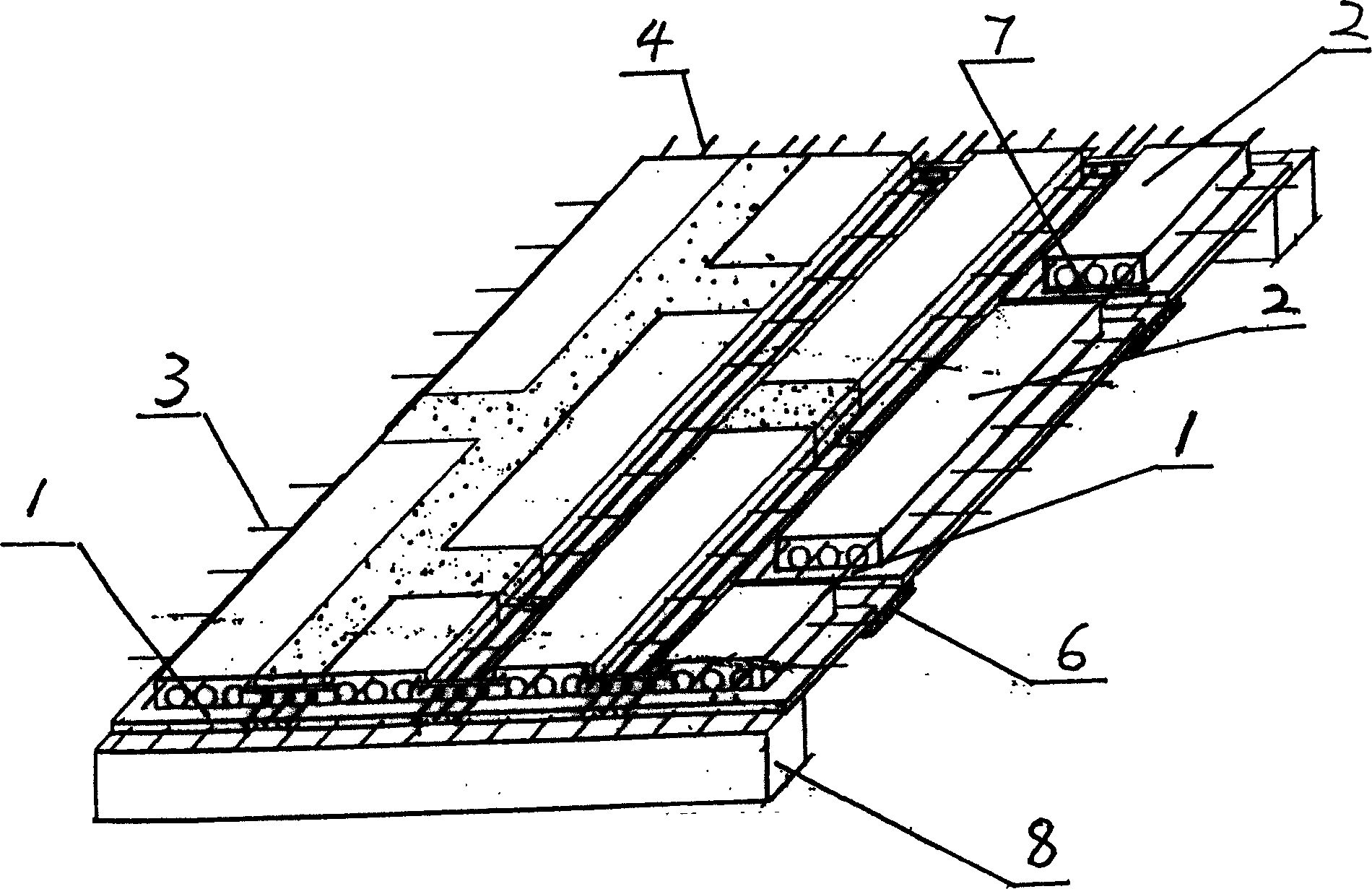

[0013] refer to Figure 5 , when assembling the floor slab, the hollow prefabricated component slab 2 is placed on the support 8 or the formwork 6 first, and the protruding platform 1 provided at the bottom of the two ends of the reinforced concrete slab body 2 can not only meet the requirement of the shelving length, but also make the adjacent The groove-shaped cavity formed by the longitudinal joint 7 of the two prefabricated comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com