Grilling surface

A component, non-stick coating technology used in the field of barbecue surfaces to solve problems such as high thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

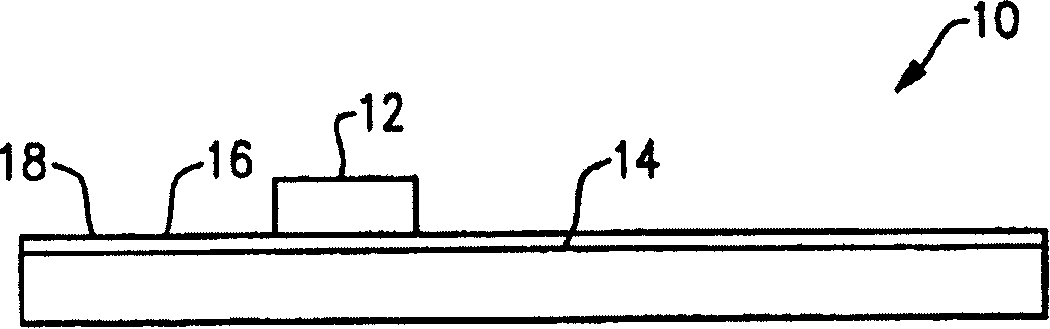

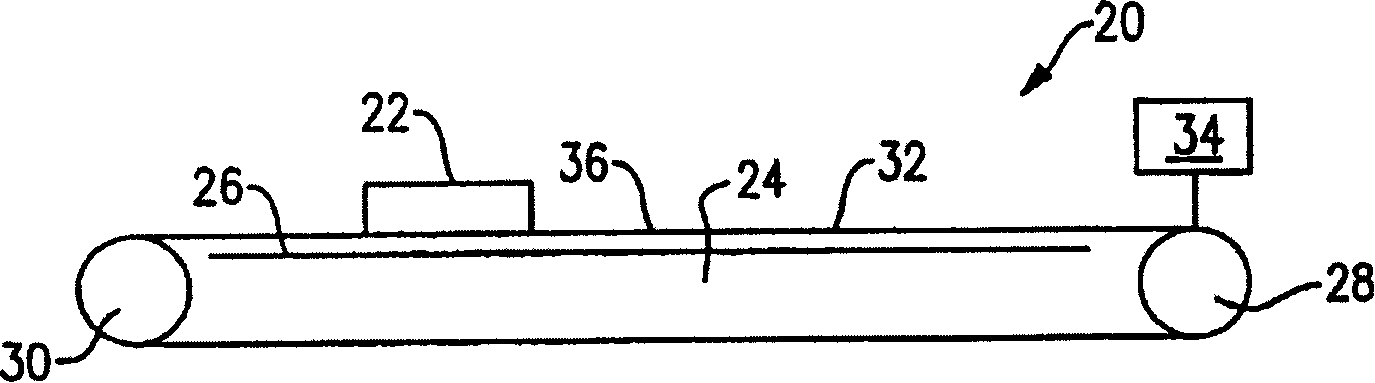

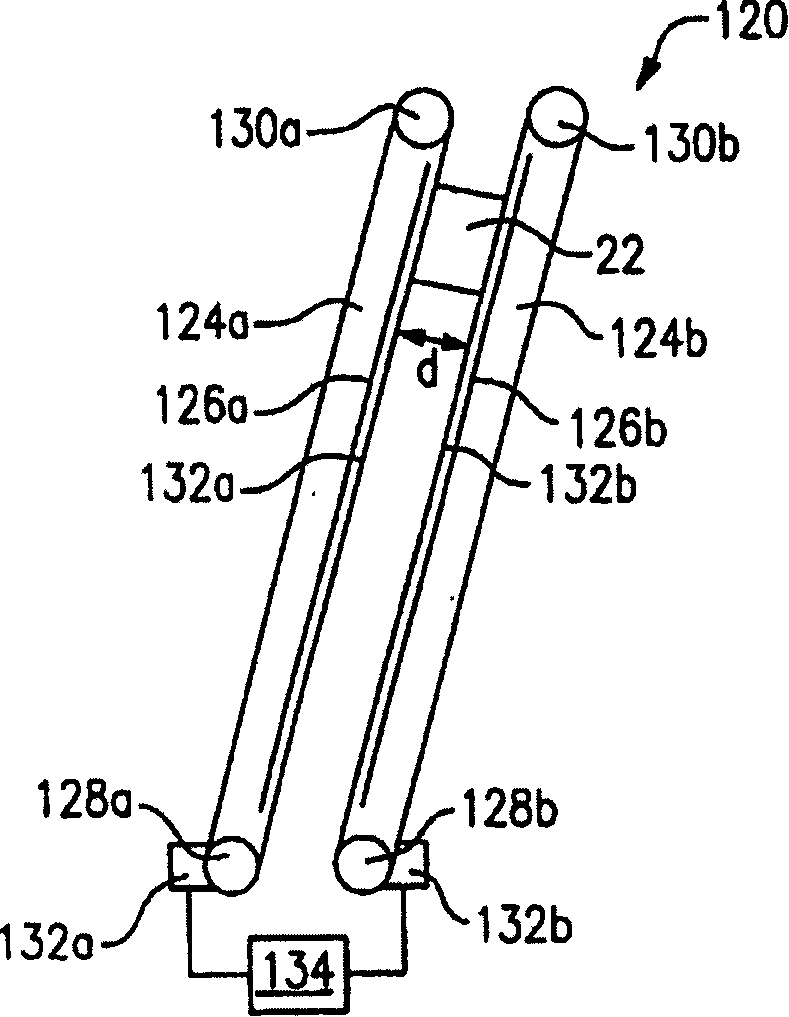

[0013] figure 1 A grilling assembly 10 for grilling food pieces such as hamburger patties is schematically illustrated. The grilling assembly includes a heater 14 for cooking the food piece 12 and a grilling surface 16 made of a suitable material having a low coefficient of thermal expansion.

[0014] In one example, the grilling surface 16 is made of Invar, a material purchased from Imphy S.A in Paris, France. TM make. Invar TM Is a metal alloy that contains iron and 36% nickel, and may contain other trace elements. Inconel has a low coefficient of thermal expansion, so there is very little displacement and expansion when heated. Although Invar is disclosed TM , but it will be appreciated that other suitable materials with a low coefficient of thermal expansion could also be used.

[0015] The grilling surface further includes a non-stick coating 18 . In one example, the non-stick coating 18 is Teflon® available from EI. DuPont Nemours and Company Corporation of Wilmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com