Transport system of glass base

A glass substrate and conveyor technology, which is applied in the field of conveying systems, can solve the problem of large damage to glass substrates, and achieve the effects of saving working time, improving production efficiency and eliminating waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

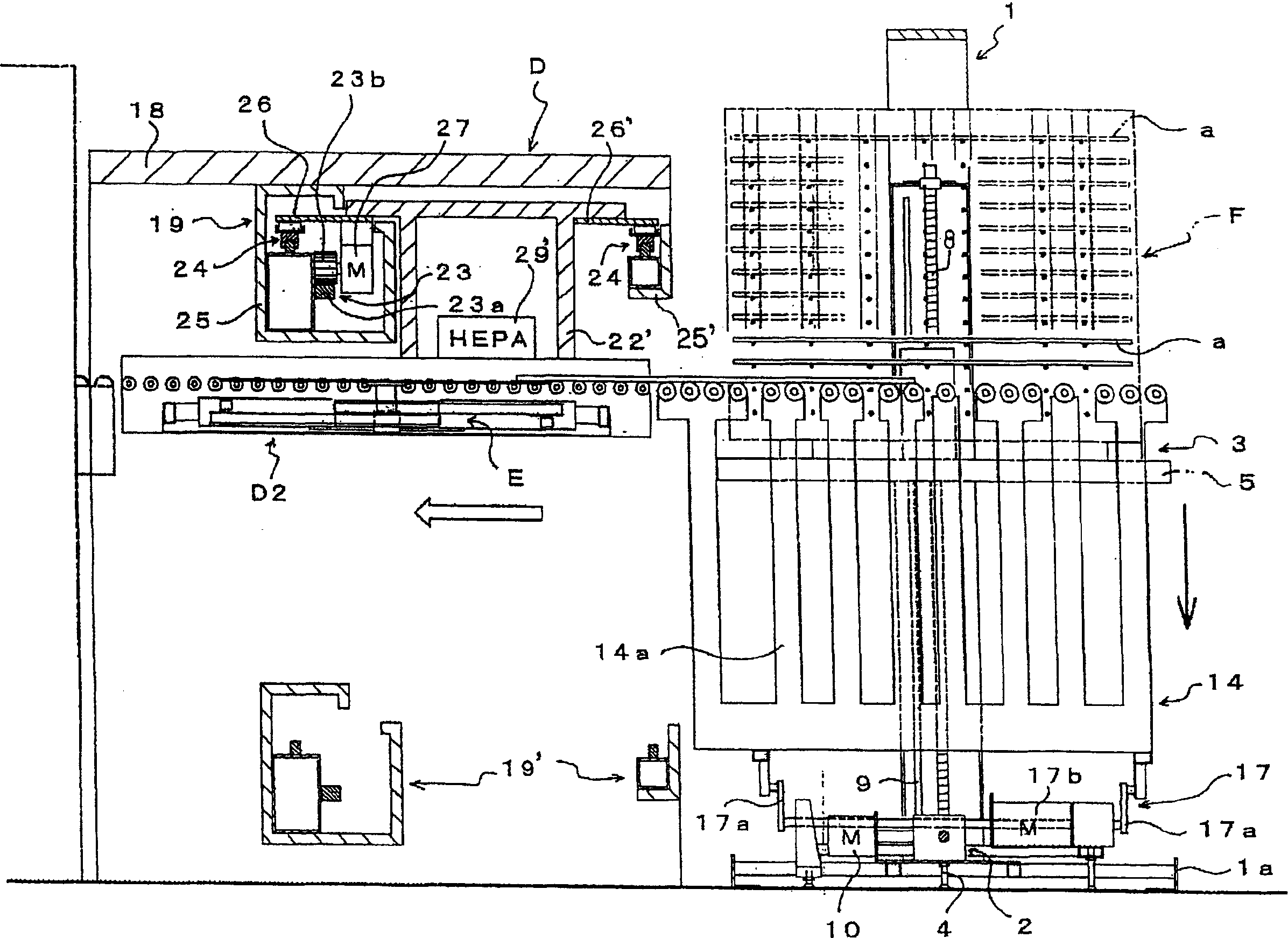

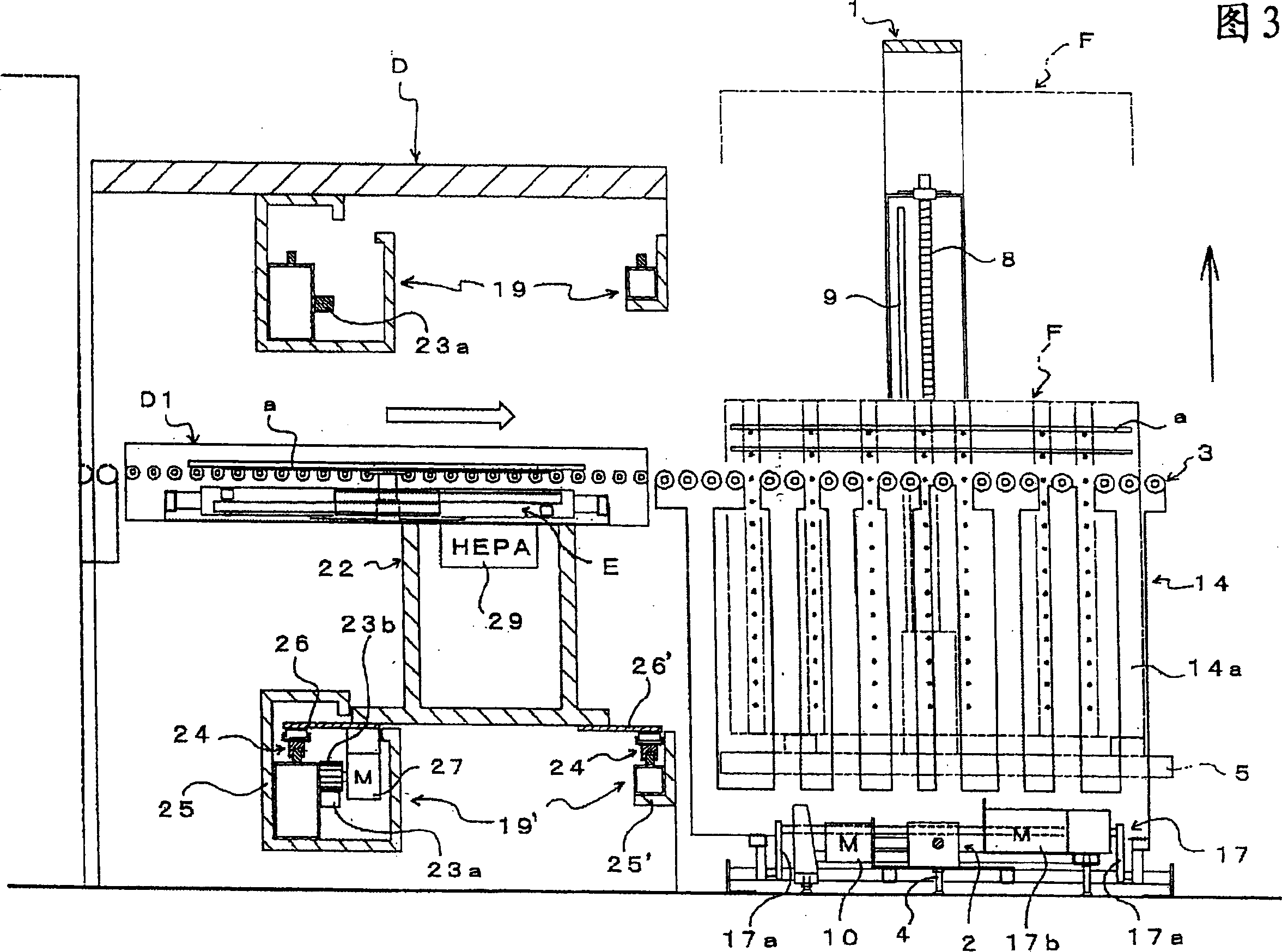

[0056] Embodiments of the transport system of the present invention will be described with reference to the drawings. In the glass substrate a shown in the drawing, in order to facilitate the understanding of the rotation or the adjustment in the left and right directions, a part of the corner is notched to represent.

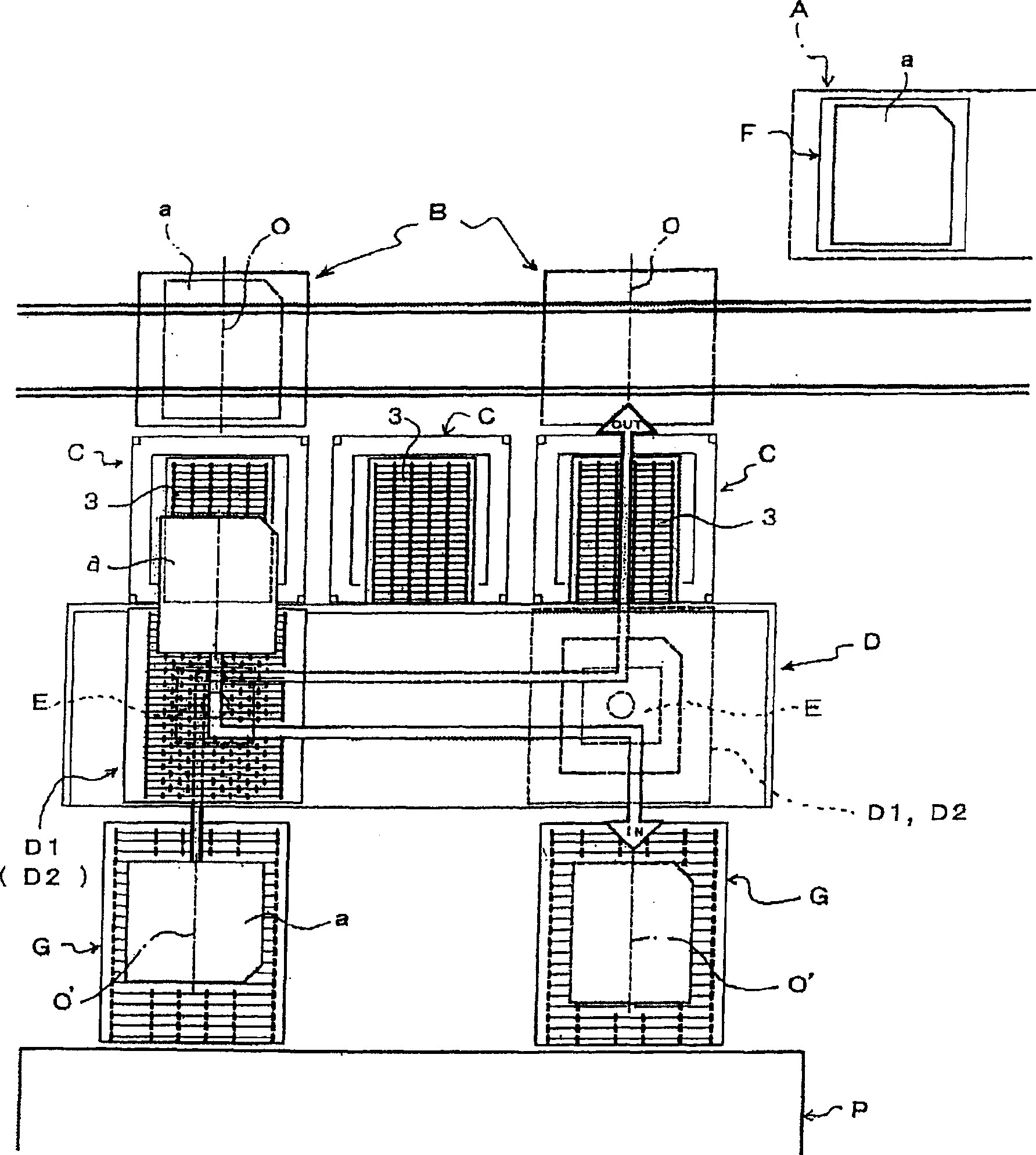

[0057] The arrangement relationship of the automatic warehouse A, the stacking crane B, the switch C, and the conveyor (hereinafter referred to as the shuttle conveyor) D composed of the conveyor D1 for receiving and the conveyor D2 for delivery, which constitute the conveying system, Such as figure 1 As shown, three exchangers C are installed along the travel path of the stacker crane B, and a shuttle conveyor D is arranged in parallel on the side where the glass substrate a is loaded / unloaded from the exchanger C. At the unloading position and the loading position of the conveyor D, the conveyance conveyor G for carrying in to the production line side P and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com