Method for implementing semiconductor laser lightbeam shaping by off-axis all internal reflecting prism array

A total internal reflection prism and beam shaping technology, applied in the field of laser technology applications, can solve problems such as reduced efficiency, achieve cost savings and reduce adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1, the beam is folded 5 times.

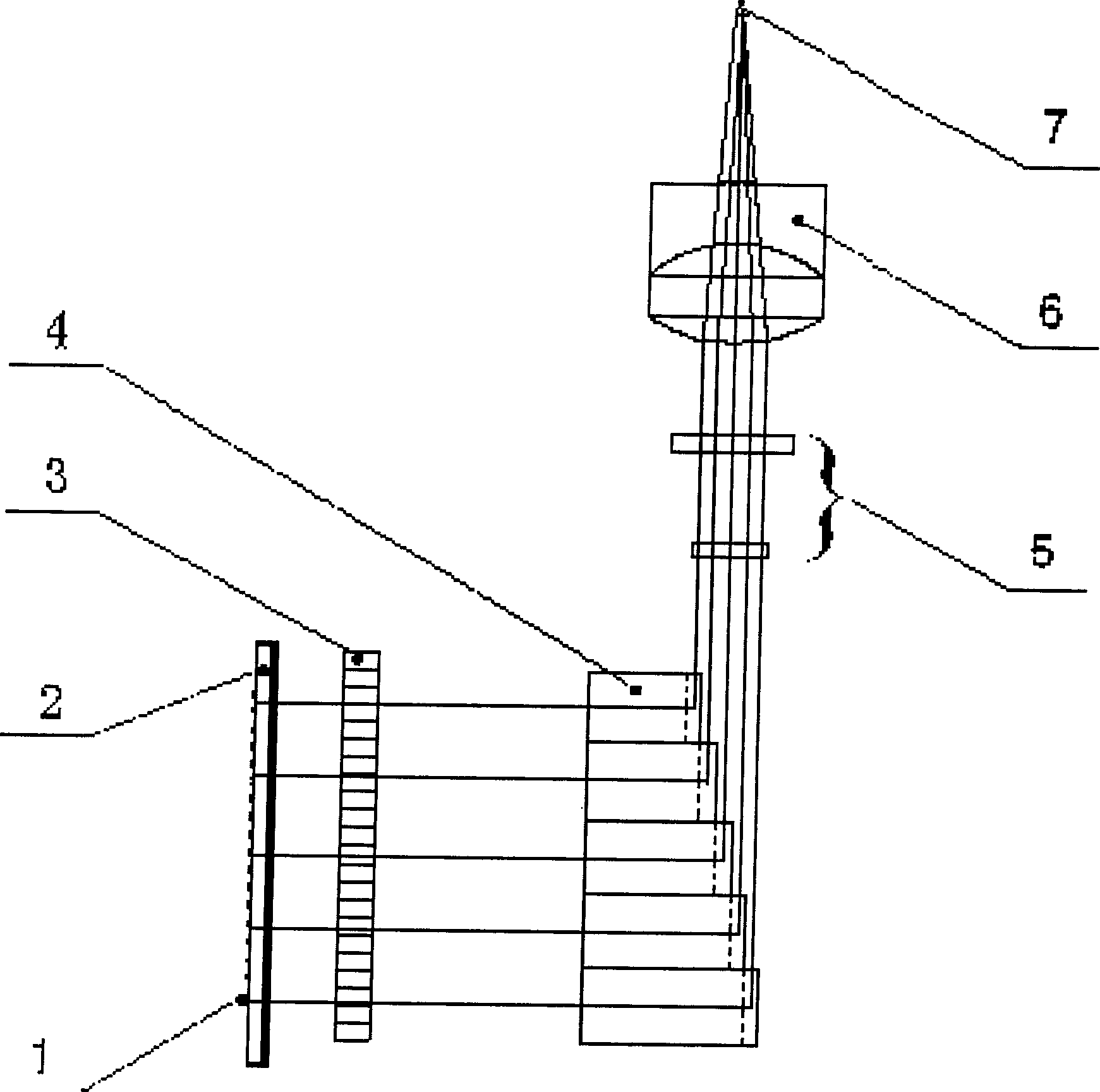

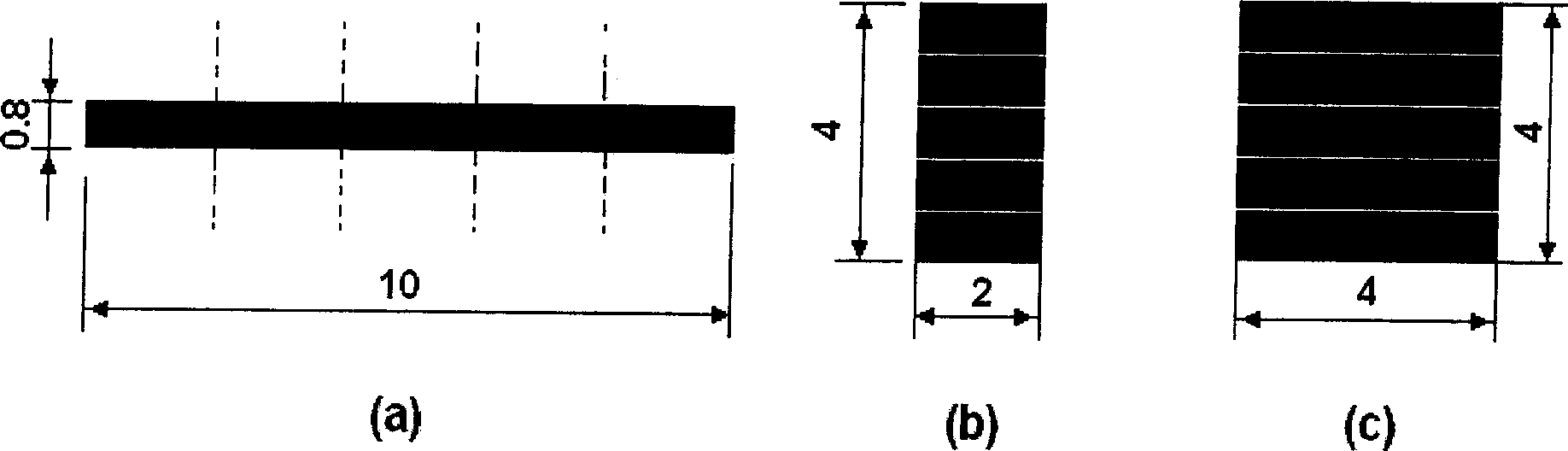

[0022] (1) if figure 1 As shown, the strip semiconductor laser forms a 10mm×0.8mm linear spot with a divergence angle of 0.2°×2.4° after being collimated by the microlens array along the fast and slow axes. The thickness of each reflective prism in the array should be 2mm, and the number of microreflectors should be 5.

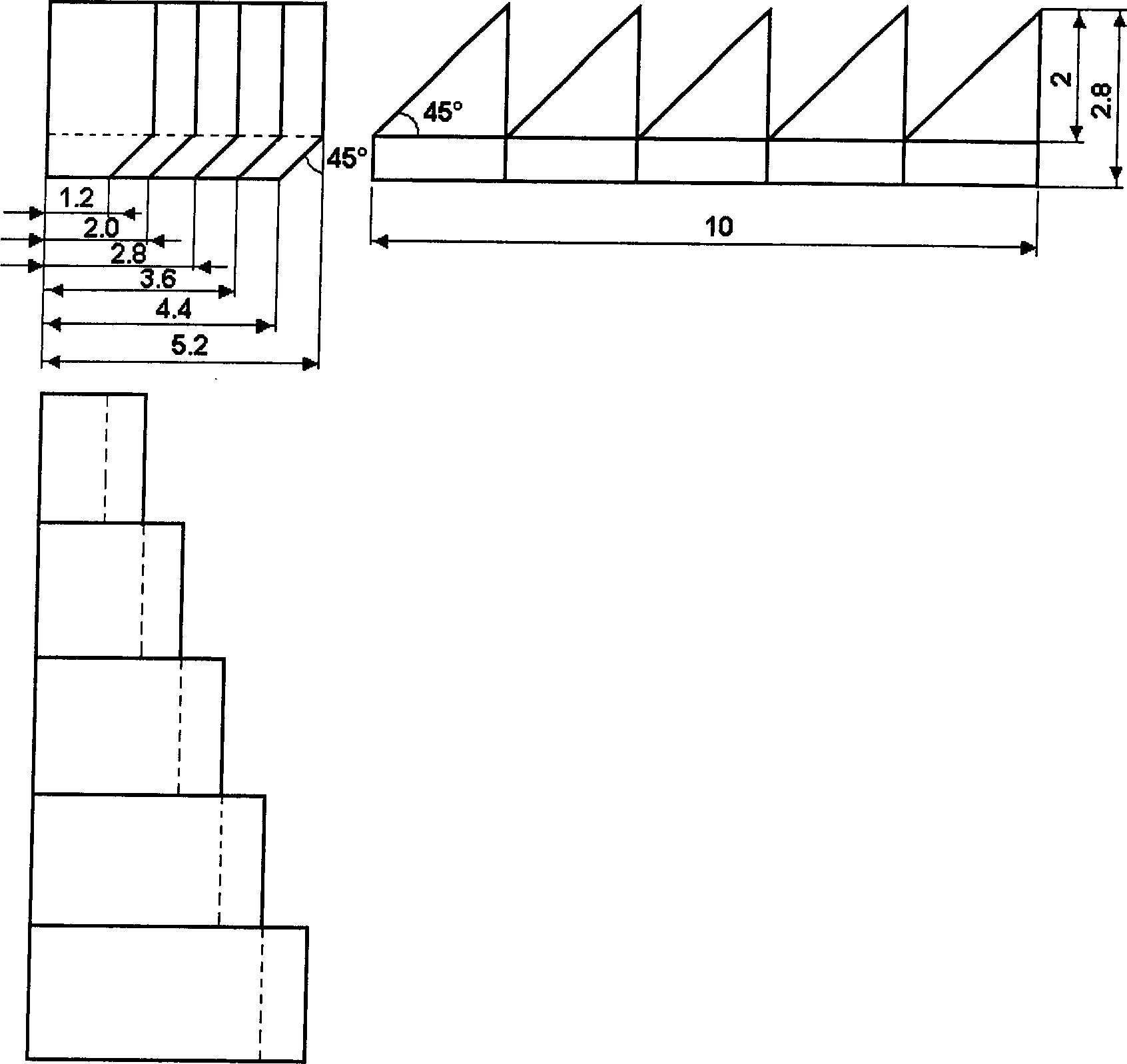

[0023] (2) According to the needs of shaping and folding times 5 times, the thickness of each reflective prism in the shaping micromirror array should be 2mm, the length of two right-angled sides of the prism is 0.8mm, and the displacement of each prism is also 0.8mm, Considering the actual production and adjustment situation, it is designed as figure 2 A shaper composed of five micromirror arrays is shown. The microprisms are individually processed and pressed figure 2 glued together.

[0024] (3) Place the direction correction microreflector group in the optical path of the collimated beam of the semicon...

Embodiment 2

[0028] Example 2, the beam is folded 7 times.

[0029] (1) if Figure 4 As shown, the strip semiconductor laser forms a 10.5mm×0.8mm linear spot with a divergence angle of 0.2°×2.4° after passing through the fast and slow axis collimating microlens array. The thickness of each reflective prism in the microreflective prism array should be 1.5mm, and the total number is 7.

[0030] (2) According to the needs of shaping and folding times 7 times, the thickness of each reflecting prism in the shaping micro-reflecting prism array should be 1.5mm, the length of two right-angled sides of the prism is 0.8mm, and the displacement of each prism is also 0.8mm , taking into account the actual production and adjustment conditions, the design is Figure 5 A shaper composed of five micro-reflecting prism arrays is shown. The microprisms are individually processed and pressed Figure 5 glued together.

[0031] (3) Place the direction correction micro-reflective prism group in the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com