Cutting equipment

A technology of outer cover and rotating brush, which is applied in the cutting of textile materials, cleaning methods using tools, textiles and papermaking, etc., and can solve problems such as inability to obtain cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

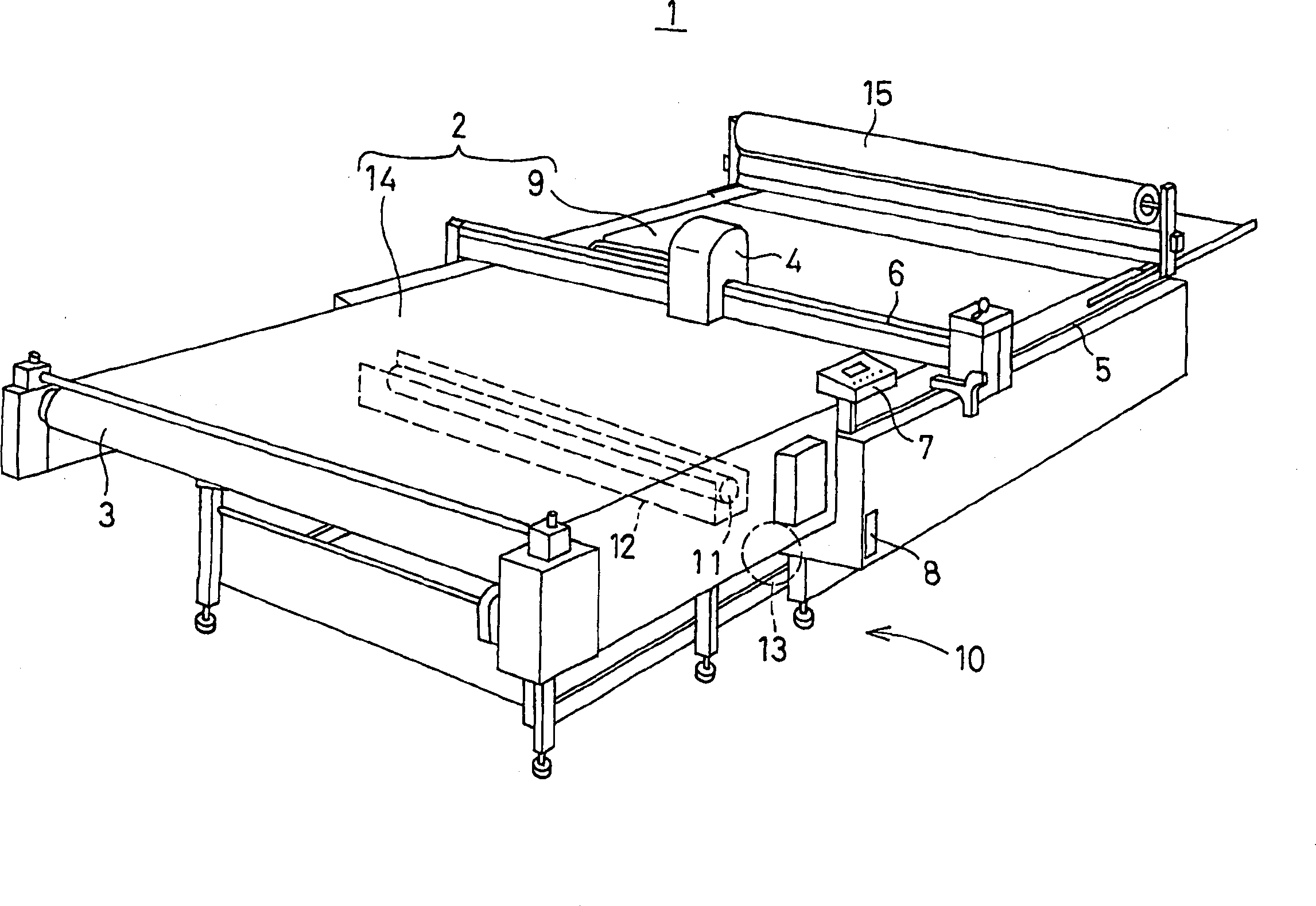

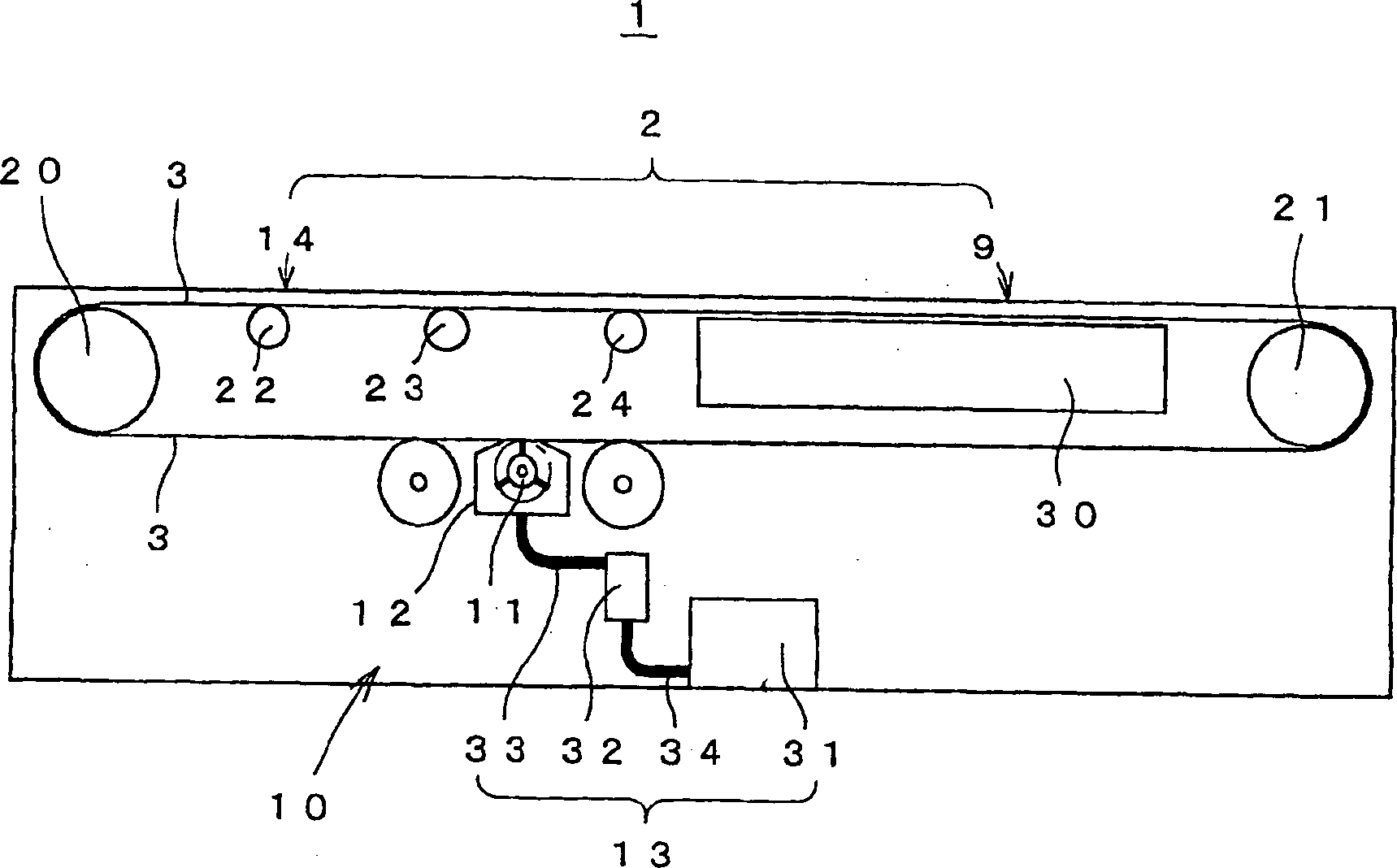

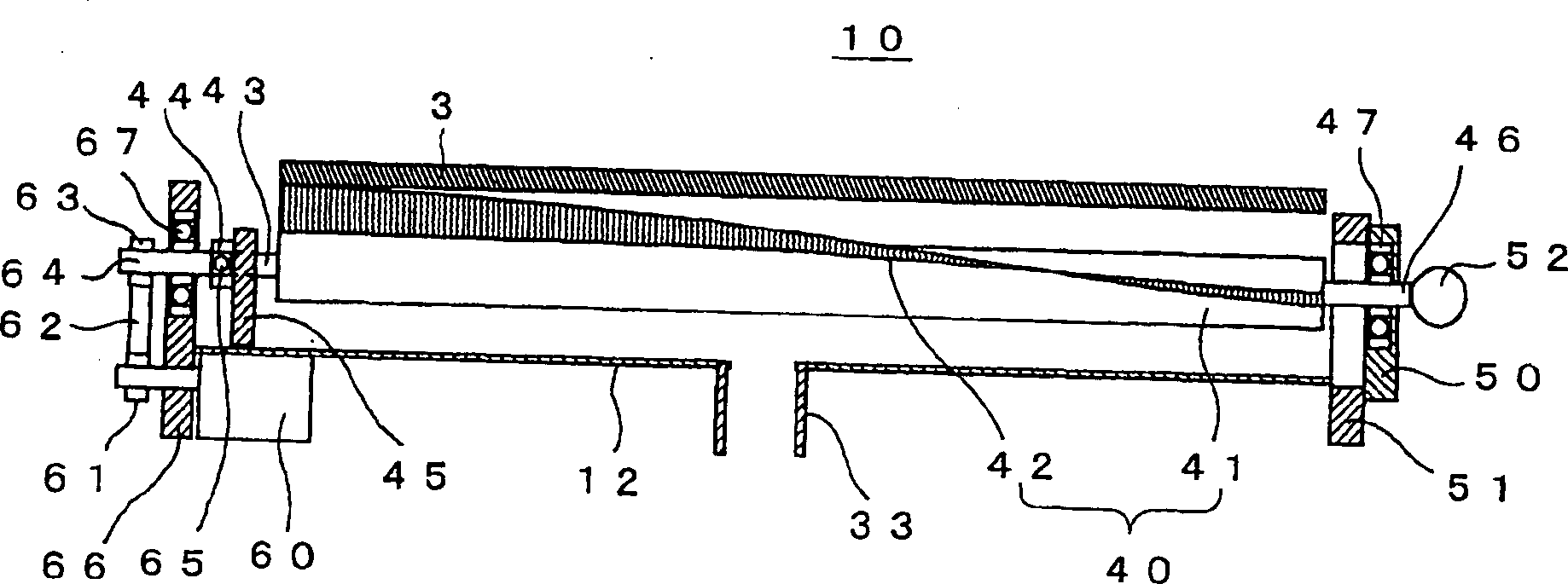

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0039] figure 1 It is a perspective view showing a simplified appearance structure of a cutting device 1 which is an embodiment of the present invention. The cutting device 1 forms a cutting workbench 2 by a grid-shaped recirculating belt 3 . In the cutting device 1 , a sheet such as a cloth to be cut is sucked and held on a conveyor-type cutting table 2 , and is cut by a cutting head 4 . In addition, sheets are omitted in the drawings. The cutting head 4 is supported by a movable rail 6 capable of reciprocating along the fixed rail 5 in the conveying direction of the belt 3 , and is capable of reciprocating along the movable rail 6 in a direction perpendicular to the conveying direction. The controller 7, according to the cutting data recorded on the recording medium such as the floppy disk inserted in the data slot 8, will combine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com