Composition for forming a functional material layer, method for forming a functional material layer

A technology of functional materials and compositions, applied in fuel cell components, fuel cells, climate sustainability, etc., can solve the problem of inability to form a catalyst uniformly dispersed reaction layer, material difficulties, and uneven nozzle hole size and shape And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

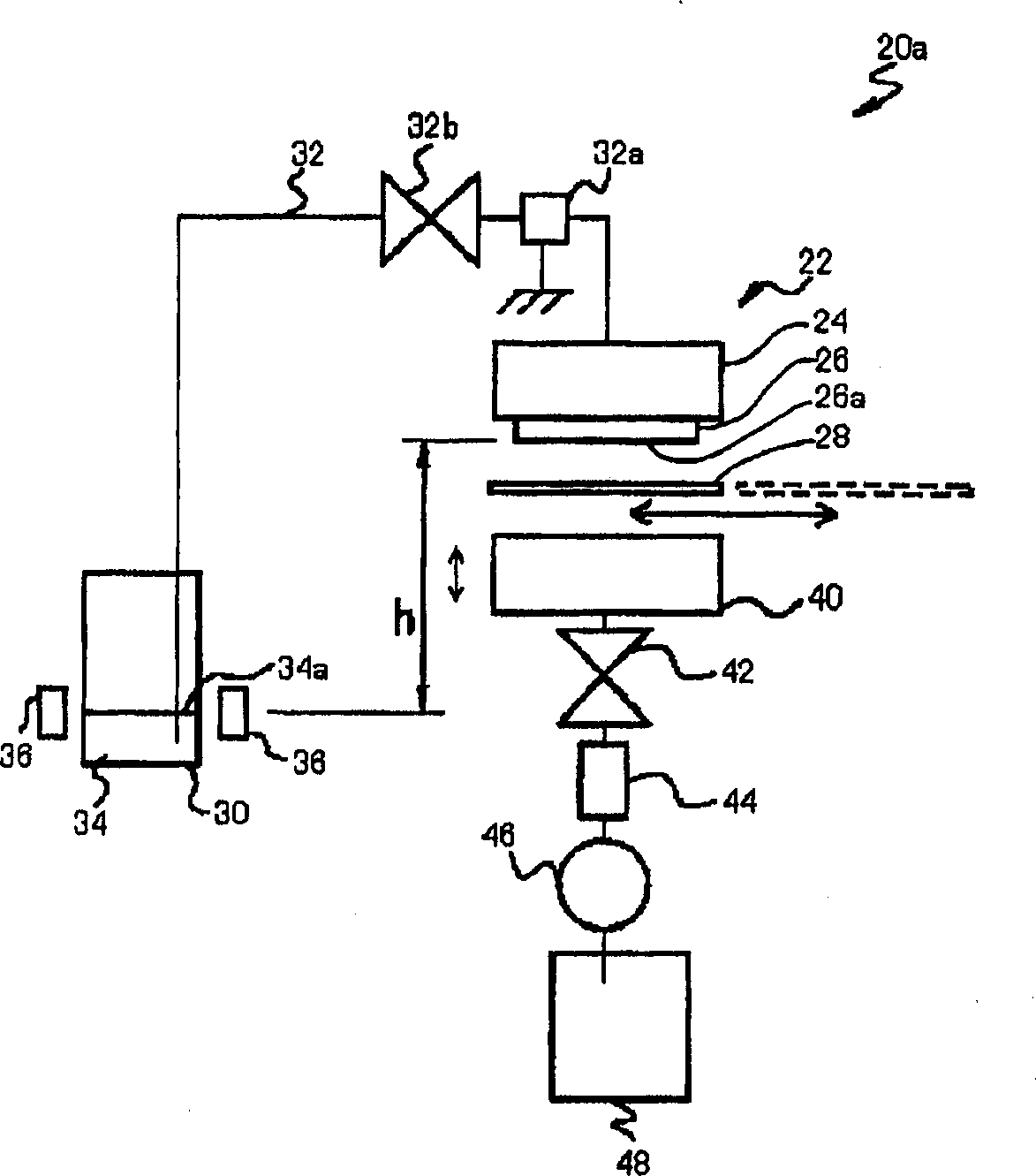

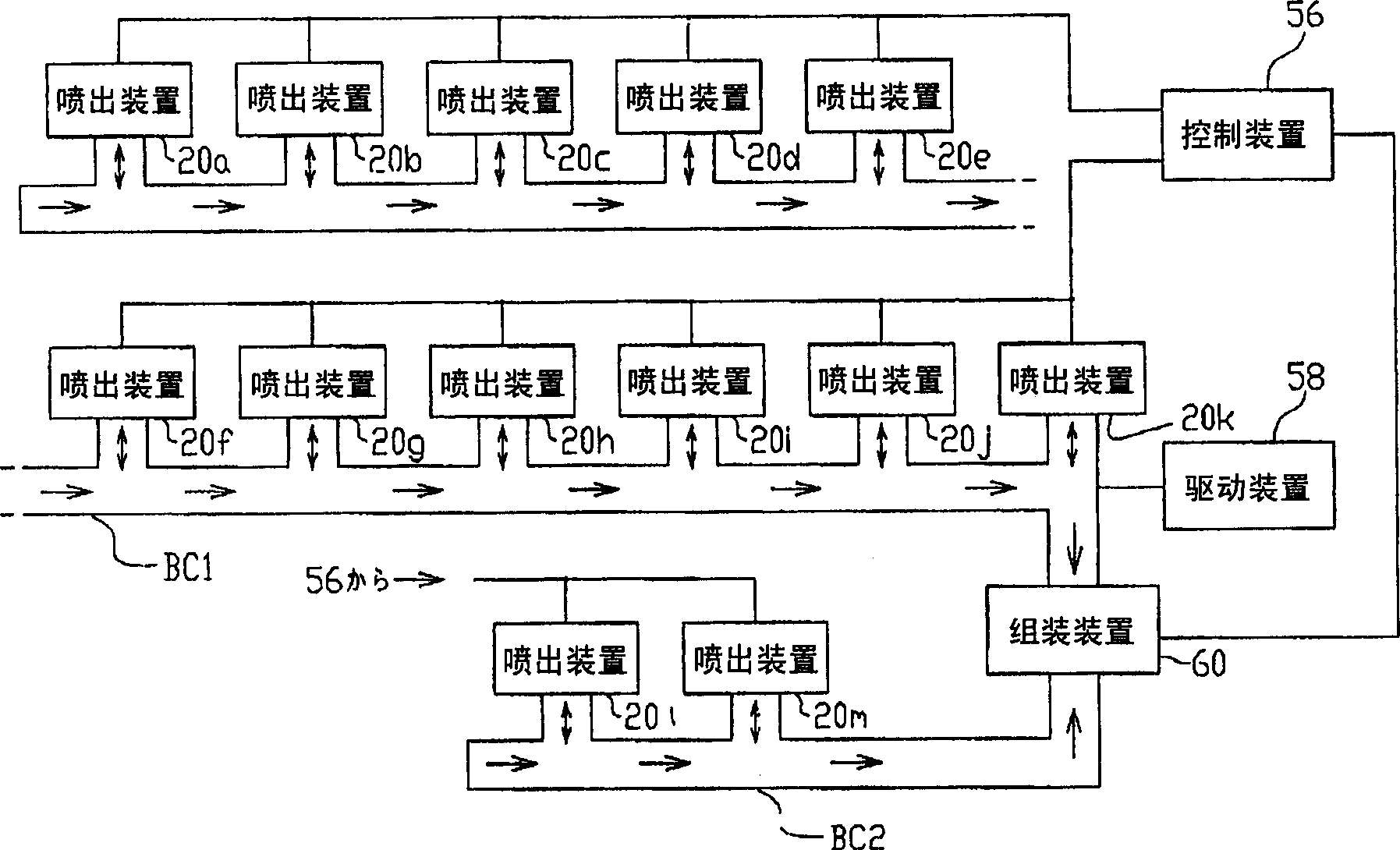

Method used

Image

Examples

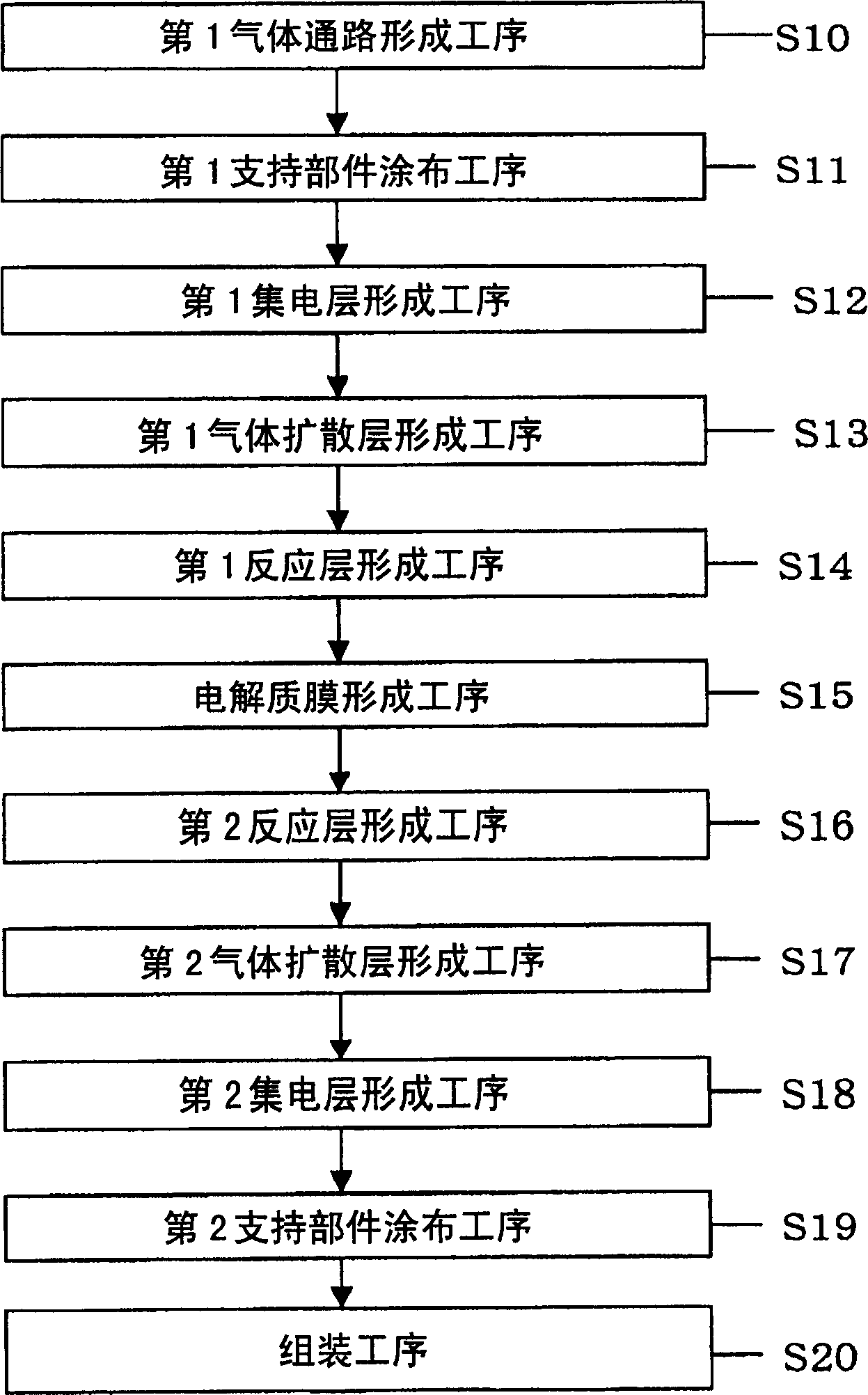

Embodiment Construction

[0046] Hereinafter, the present invention will be described by dividing it into 1) a composition for forming a functional material layer, 2) a method for forming a functional material layer, 3) a method for manufacturing a fuel cell, 4) an electronic device, and 5) an automobile.

[0047] 1) Composition for forming functional material layer

[0048] The composition for forming a functional material layer of the present invention is a non-corrosive composition for forming a functional material layer which is sprayed out by a spraying device, and is characterized in that, by adding a predetermined amount of alkali to a strong acidic functional material solution, , to make a composition that does not corrode the components of the ejection device.

[0049] The functional material used in the functional material layer-forming composition of the present invention is not particularly limited as long as it is strongly acidic and may etch components of a discharge device when in contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com