Punching mould appts.and metal punching method

A technology for stamping dies and metal plates, which is applied in the field of metal stamping processing, and can solve problems such as inability to confirm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] As described in the background art, the thin metal plate also goes through the preliminary forming process, the punching and deburring process, and reaches the flattening process.

[0035] This press die device for heat exchange fins is composed of an upper die and a lower die that are openably and closably provided, and a die plate (not shown) that constitutes the upper die holds a die for flattening (not shown). ).

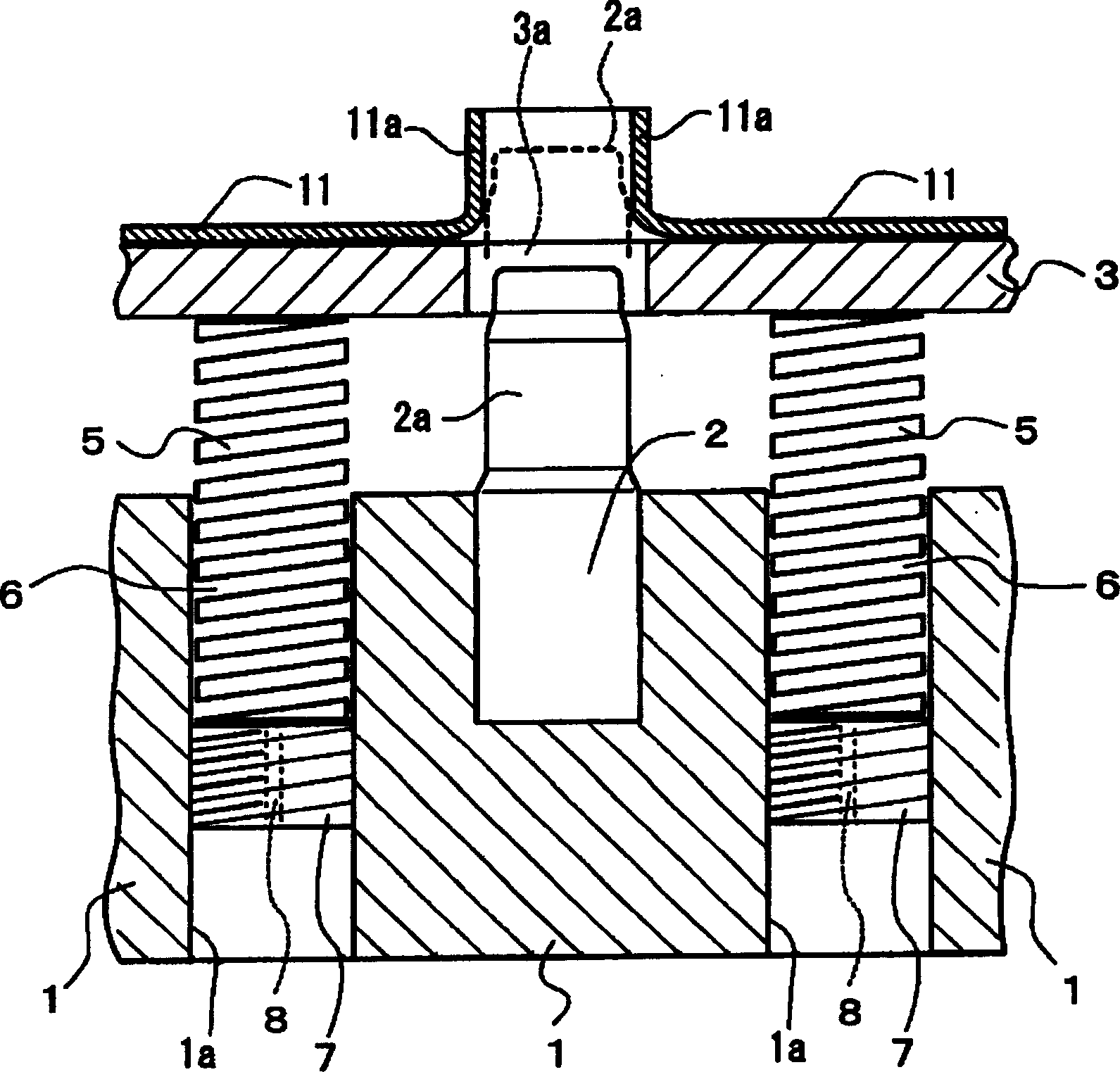

[0036]On the other hand, a flattening punch 2 is fixed to the punch plate 1 constituting the lower die. Above the punch connecting plate 1, a stripper plate 3 is provided at a certain distance from the connecting plate 1. The stripper plate 3 is elastically supported by a spring (coil spring 5) as an elastic member. The stripper plate 3 is provided with a penetration hole 3a through which the head end 2a of the flattening punch 2 can pass, and the head end 2a of the flattening punch 2 is in a state in which no load is applied to the stripper plate 3. T...

Embodiment approach 2

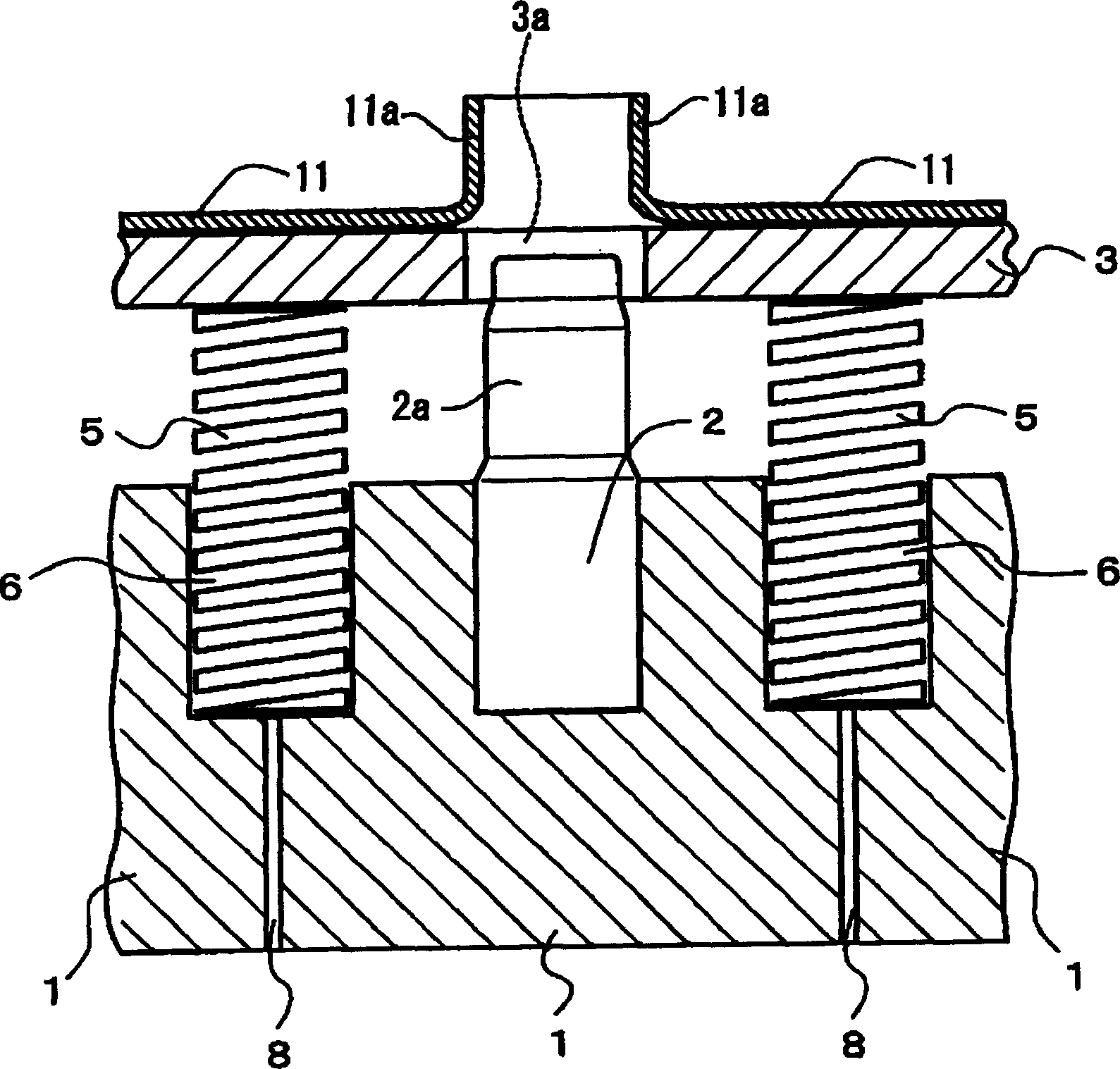

[0050] figure 2 Embodiment 2 which is different from Embodiment 1 described above is shown. In this Embodiment 2, with figure 1 Unlike the first embodiment shown, the concave portion 6 for accommodating the spring 5 is formed as a bottomed hole formed on the upper surface of the punch tab 1 . In addition, a discharge passage 8 for discharging the lubricating liquid is provided through the punch adapter plate 1 from the lower surface of the punch adapter plate 1 to the recessed portion 6, and is provided with the punch adapter plate 1. figure 1 In the same manner as in the illustrated embodiment 1, the lubricating liquid that has flowed into the recessed portion 6 is discharged from the discharge passage 8 . Other structures are due to figure 1 Since Embodiment 1 shown is the same, the same number is used for the same member, and the description is abbreviate|omitted.

Embodiment approach 3

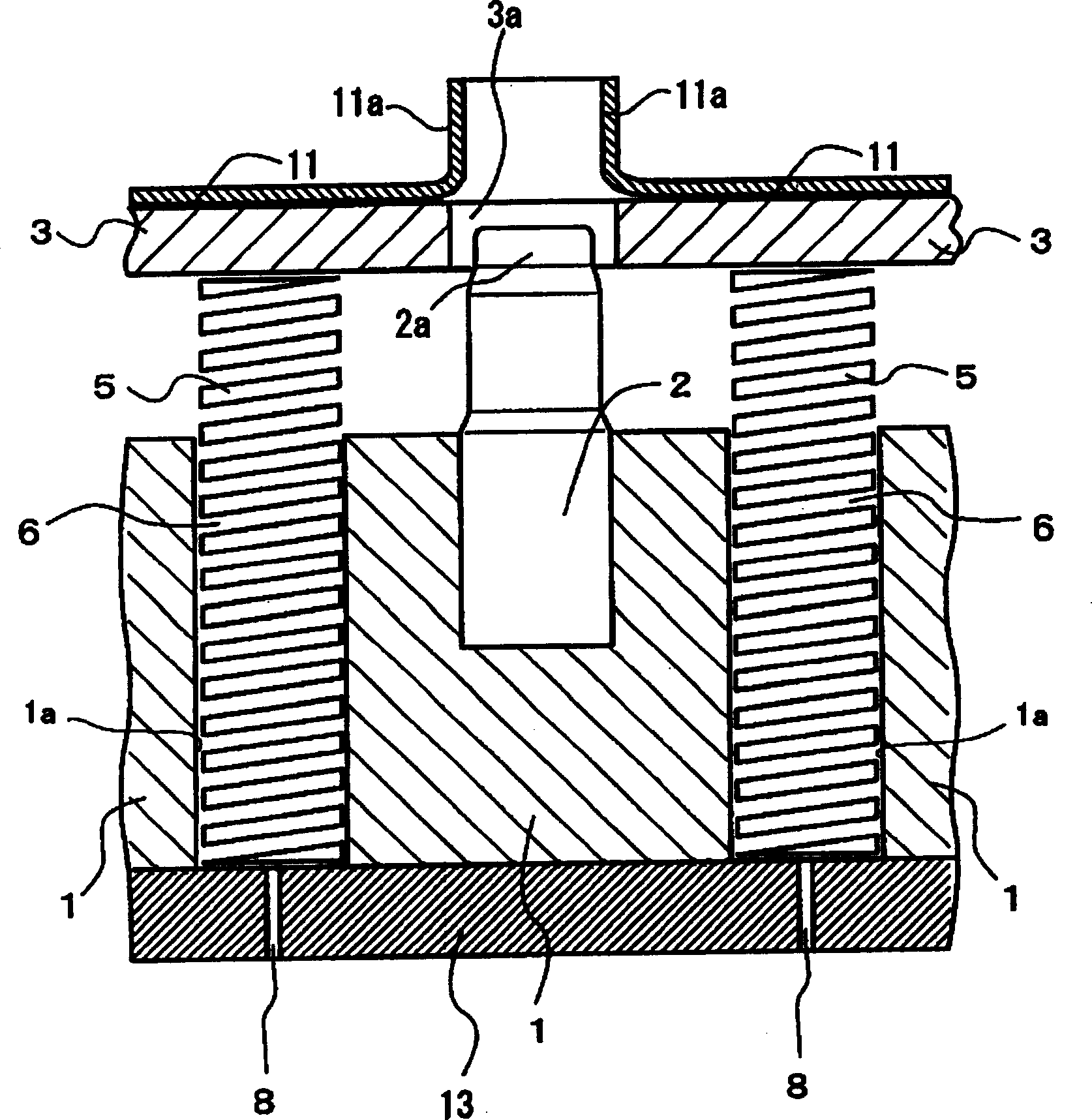

[0052] image 3 Embodiment 3, which is different from the above-described embodiment, is shown. In the third embodiment, the concave portion 6 for accommodating the spring 5 is constituted by the inner side surface of the through hole formed in the punch adapter plate 1 and the upper surface of the support plate 13 arranged on the lower side of the punch adapter plate 1 . Further, the discharge passage 8 communicating with the recessed portion 6 is formed through the support plate 13 , so that the lubricating liquid flowing into the recessed portion 6 is discharged from the discharge passage 8 as in the above-described embodiment. Since other structures are the same as those of the above-described embodiment, the same reference numerals are used for the same members, and the description thereof will be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com