Device with stepping type short tubes for removing inhalable particulates by thermophoresis

A remover and step-by-step technology, which is applied to the field of step-by-step short-tube inhalable particulate matter thermophoresis removers, can solve the problems of complex methods and difficult to apply engineering practice, and achieves simple control, reliable performance, and easy marketability. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific structure, working process and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

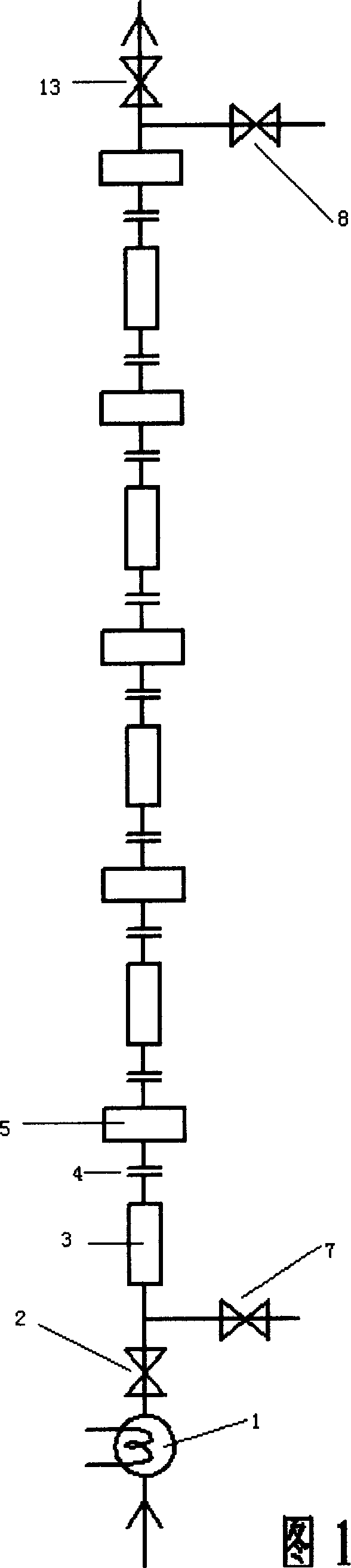

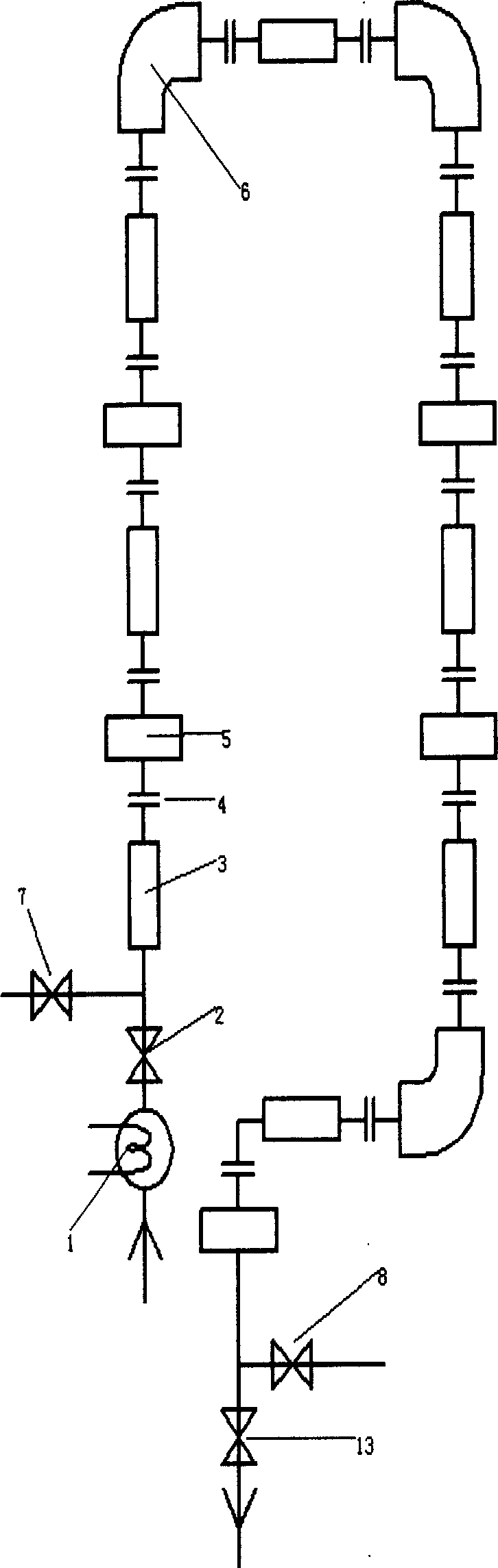

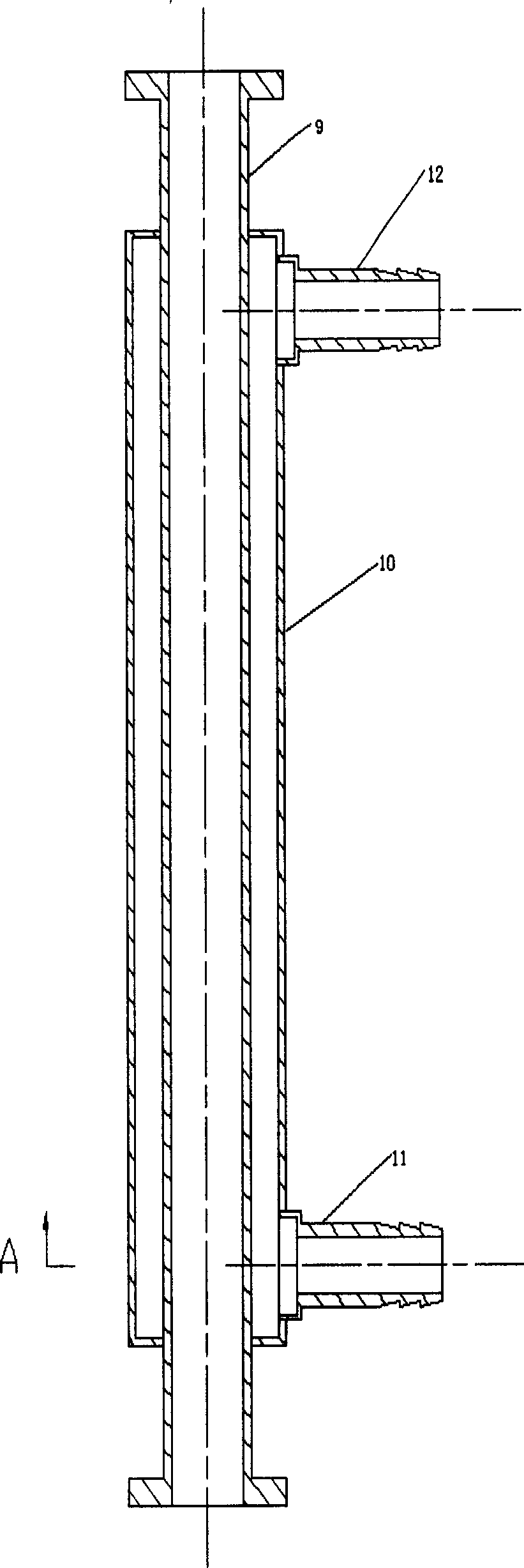

[0012] Fig. 1 is a schematic structural diagram of a straight channel stepping short tube inhalable particle thermophoresis remover, which is straight in shape and includes a thermophoresis working section 3, a transition flow section 5, an inlet valve 2, an outlet valve 13 and a The dust cleaning bypass system between the inlet valve and the outlet valve; the thermophoresis working section and the transition flow section are arranged alternately, and the two are connected by a flange 4; the thermophoresis working section adopts a water inlet 11 and a water outlet The annular bushing of the water cooling system of hole 12, annular bushing is made of interior pipe 9 and outer casing 10 (as image 3 , 4), the length of the annular casing is generally 0.1 to 2.0m, preferably 0.5 to 1.2m, and the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com