Bridge ship loader-unloader

A loading and unloading mechanism and bridge-type technology, which is applied in the directions of loading/unloading, transportation and packaging, etc., can solve problems such as belt deviation, affecting transportation operations, and affecting the working distance of ship unloaders, so as to reduce the cost and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

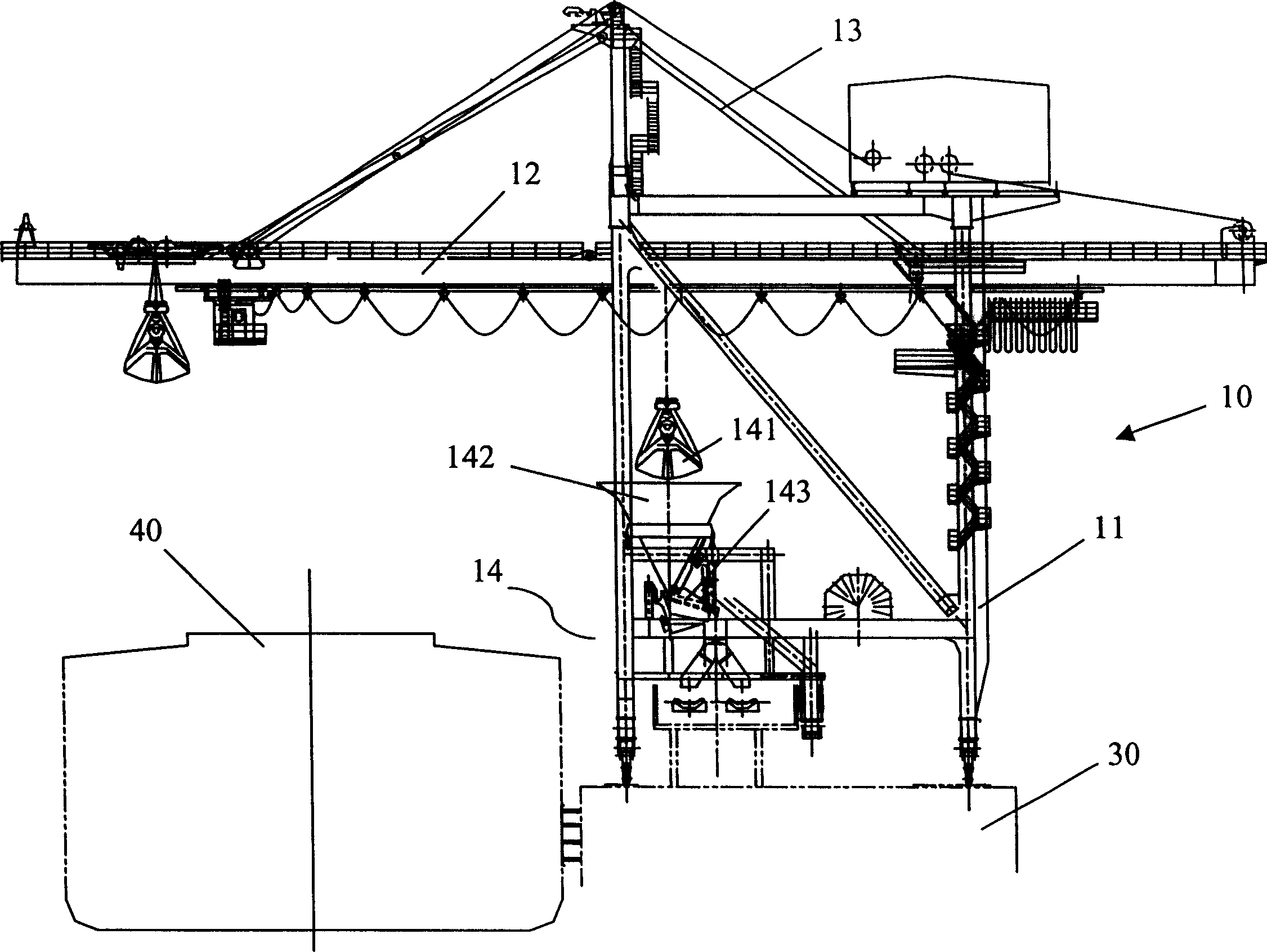

[0027] In order to facilitate the understanding of the ship loading and unloading machine of the present invention, please first combine figure 1 As shown, a simple description is made to the structure of the traditional ship unloader:

[0028] figure 1 Among them, the ship unloader 10 includes a derrick 11, a girder 12, a hanger 13, and a loading and unloading mechanism 14,

[0029] The girder 12 is horizontally arranged on the derrick 11, the hanger 13 is arranged on the derrick 11 and connected with the girder 12, the loading and unloading mechanism 14 is located under the girder 12 and the derrick 11,

[0030] The loading and unloading mechanism 14 includes a grab 141 , a funnel 142 , and a feeder 143 . The grab 141 is slidably arranged on the girder 12 , and the outlet of the funnel 142 is connected to the feeder 143 .

[0031] figure 1 Among them, 30 is the wharf, and 40 is the ship that needs to unload materials.

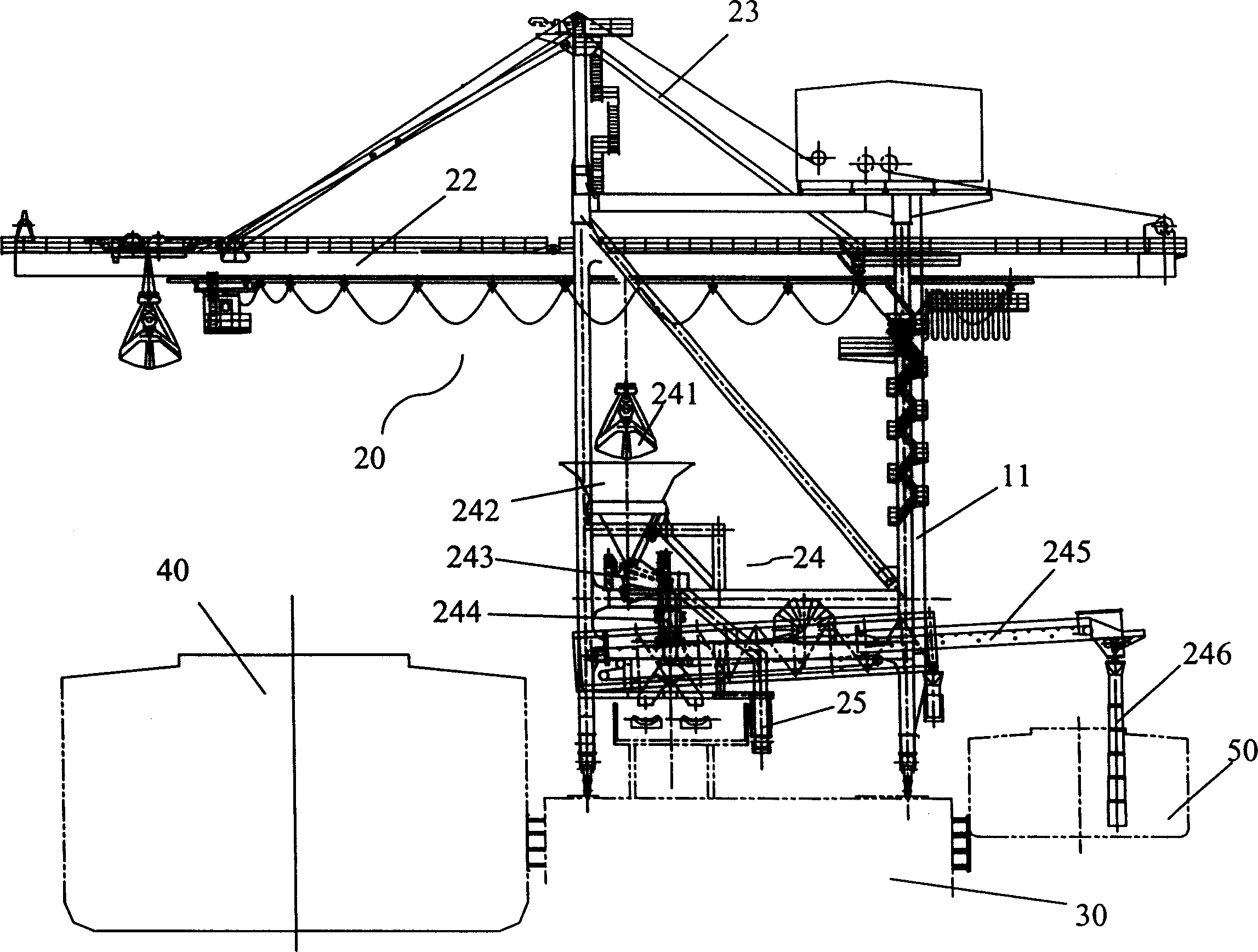

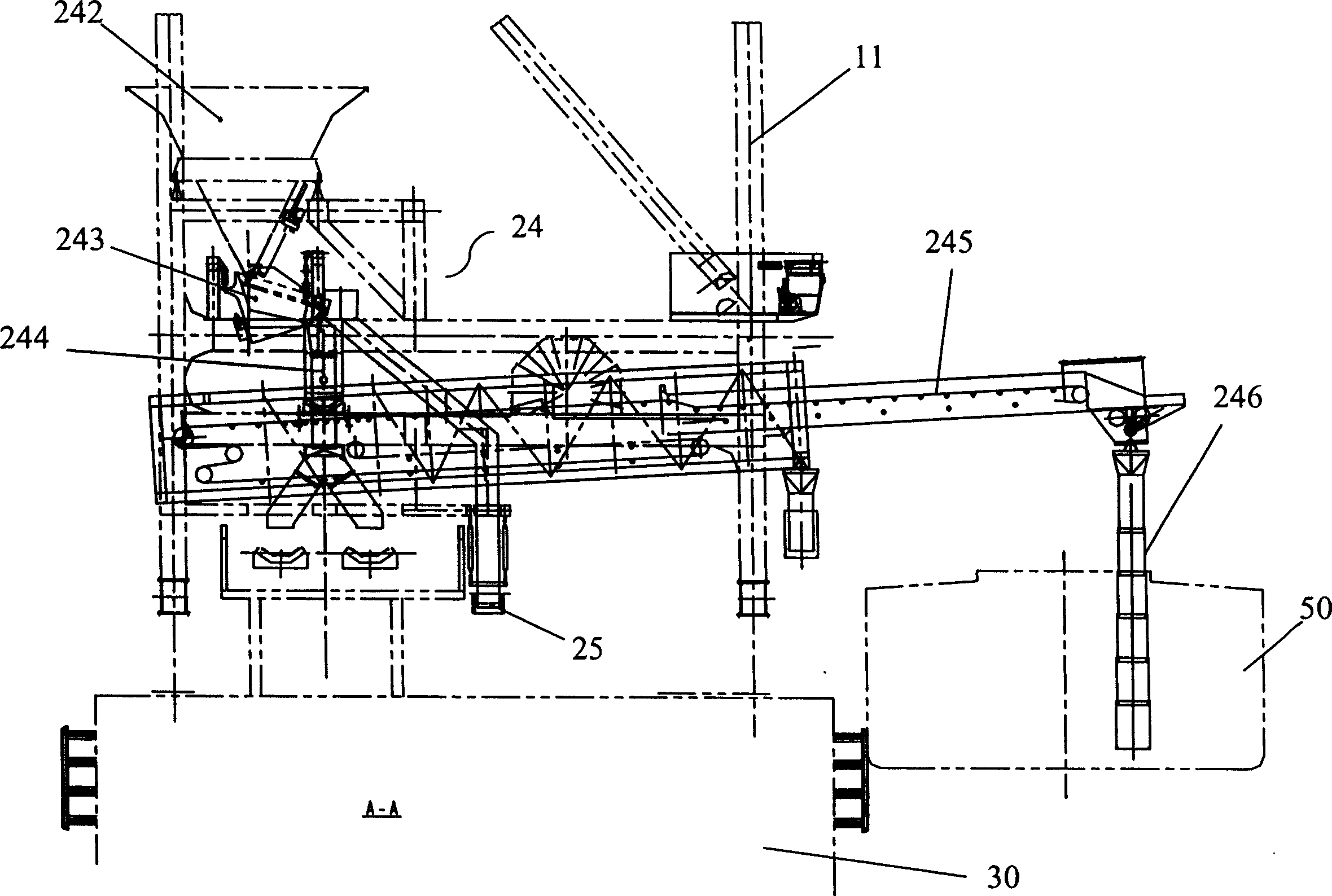

[0032] see again figure 2 as shown,

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com