Large internal combustion engine with supercharger

An internal combustion engine, large-scale technology, applied in the direction of internal combustion piston engines, combustion engines, engine components, etc., can solve problems such as engine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

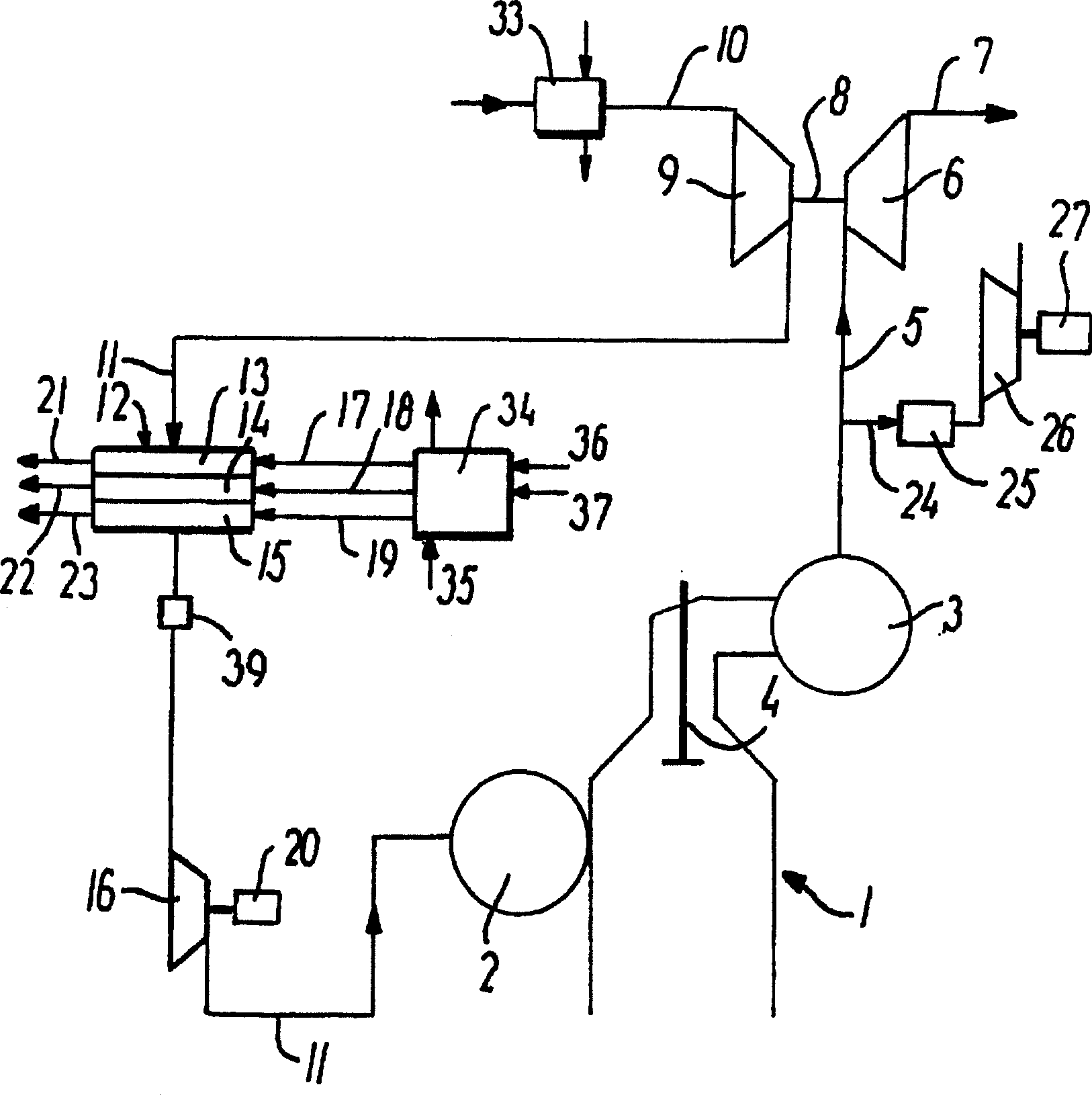

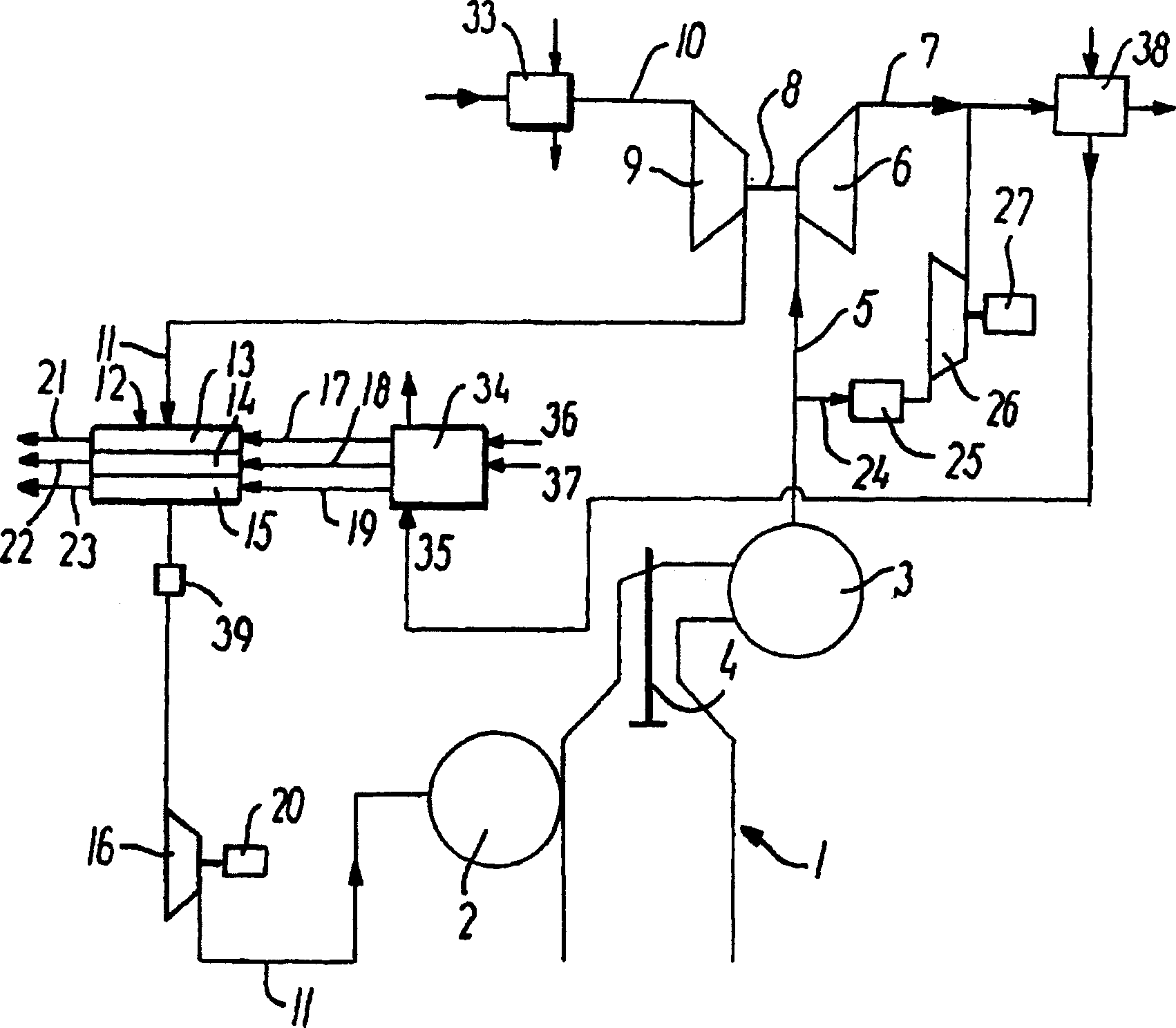

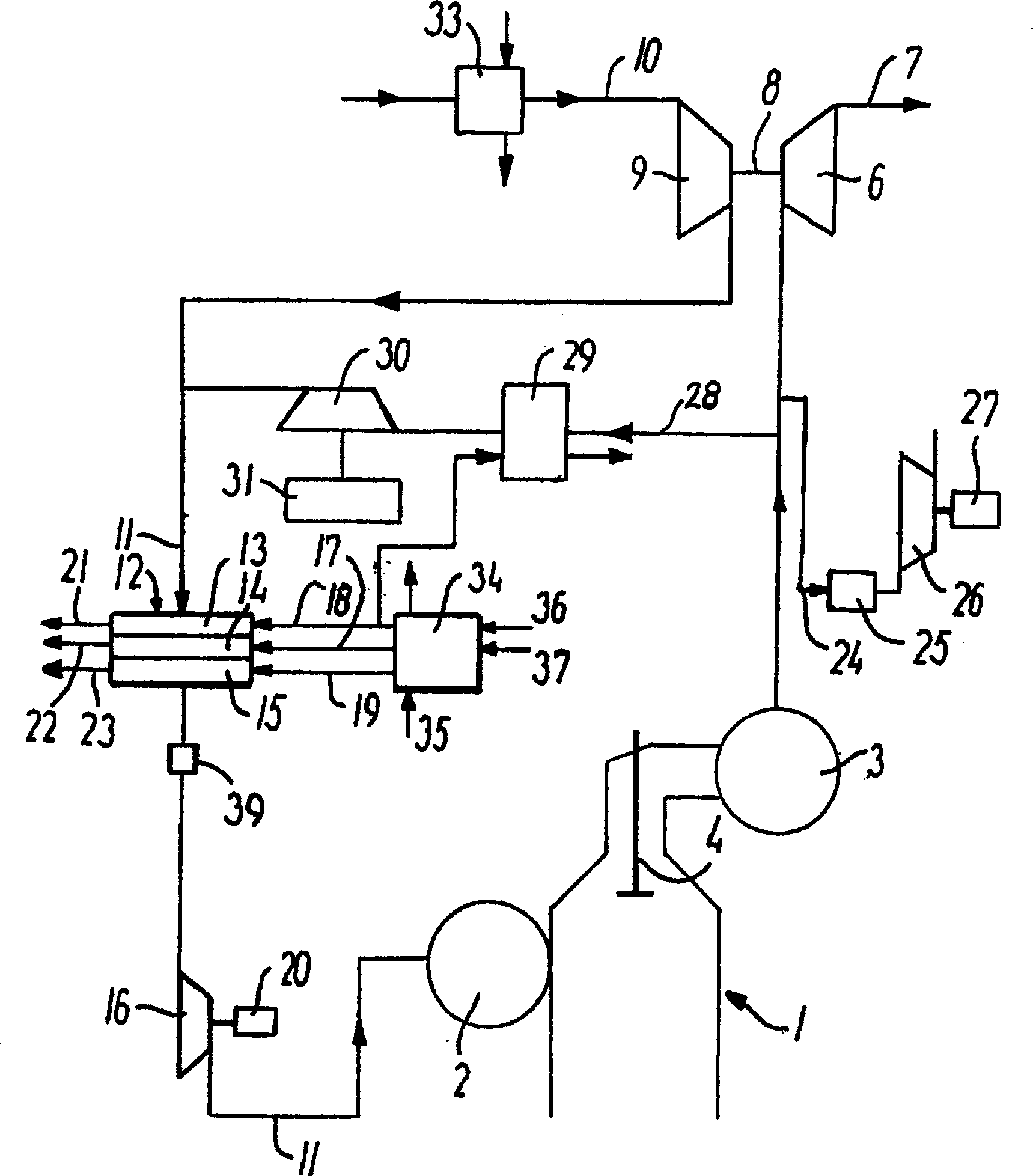

example 1

[0052] The following example describes the mode of operation of a scrubber in an engine plant, where the recirculation gas is purified and humidified in a humidification unit 29 and all charge air is humidified in a two-stage humidification unit 12 . The operating state of the engine can be selected so that the maximum amount of energy is shunted from the exhaust flow. For simplicity, the calculation is based on the engine at full load, the input power is 25,000KW and the nominal pressure of the charge air is 360Kpa.

[0053] The engine is running at 100% load, the ambient air temperature is 25°C and the relative humidity is 30%, which means that the intake air will contain about 6g water / kg air. The air consumption of the engine is about 55kg / s. After passing through the compressor 9, the temperature of the air is T1=190° C., and the relative humidity is 0.25%.

[0054] In the first humidification section 13, water is supplied at a flow rate of 13 l / s to the atomizer nozzles...

example 2

[0059] This example shows the possibility of selecting the operating state of the engine in case of low thermal load on the engine. Under the same ambient conditions and engine load as above, the atomizer nozzles in the first flushing section 12 are supplied with seawater at a temperature of 30°C and a flow rate of at least 20 l / s, thus altering the charge air by evaporation The temperature is about T1=75°C, the humidity is about 90% relative temperature, and the absolute humidity is about 65g / kg.

[0060] In the second flushing section 13, water is supplied with a temperature of about 30° C. and a flow rate of 60 l / s. This cools the charge air to a temperature of about 37°C and an absolute humidity of the air at 100% saturated gas of about 11 g / kg.

[0061] Thus, a low thermal load setting of the engine can be achieved, for example, when a thermal overload signal of the engine is present.

example 3

[0063] This example shows the possibility of selecting the operating state of the engine when the engine has a medium heat load. Under the same ambient conditions and engine load as above, the sprayer nozzles in the first scourer section 12 are supplied with seawater at a temperature of 50° C. and a flow rate of about 13 l / s. This changes the temperature of the charge air to approximately 75°C, while the charge air is humidified to approximately 80% relative humidity. The absolute temperature thus reaches a level of approximately 59 g / kg.

[0064] In the second flusher section 13, water is supplied with a temperature of about 76° C. and a flow rate of 50 l / s. This changes the temperature of the charge air to about 75°C and the absolute humidity of the air at 100% saturated gas is about 76g / kg.

[0065] Thus, a moderate thermal load setting of the engine can be achieved, the engine can be operated with reduced NOx emissions and with less energy diverted from the exhaust flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com