Multilayer ceramic electronic part, circuit board and method for producing ceramic green sheet used for manufacturing those part and circuit board

一种陶瓷生片、多层陶瓷的技术,应用在多层电路制造、印刷电路制造、电路基板材料等方向,能够解决绝缘层影响、内部电极图形截面形状增加等问题,达到防止堆叠未对准的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

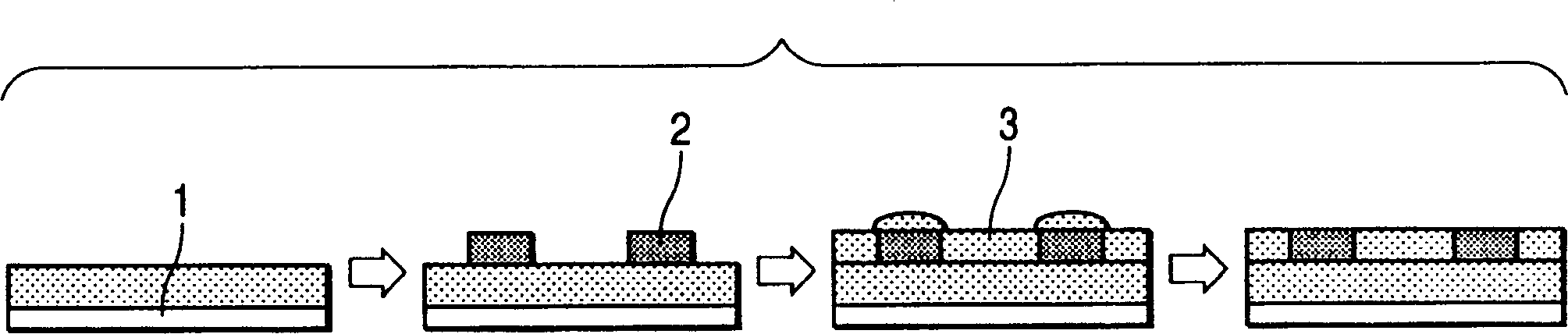

[0040] Such as figure 1 As shown, internal electrodes 2 having a predetermined thickness are formed on substrate 1 by an arbitrary process. A paste of photosensitive ceramic 3 is then applied on the internal electrode surfaces. The paste is dried so that its thickness is substantially equal to that of the internal electrodes just before exposure. Subsequently, after passing the Figure 4 While masking the internal electrode pattern with the photomask 4 shown, the photosensitive ceramic paste is irradiated with light from the upper side of the substrate for exposure. In this process, the surface of the photosensitive ceramic paste is selectively cured while controlling the exposure amount in such a manner that the exposed portion on the surface of the photosensitive ceramic paste is cured. Unexposed portions of the photosensitive ceramic paste are removed by a development process to form a substantially planar layer including internal electrodes.

[0041] By stacking a plur...

Embodiment 2

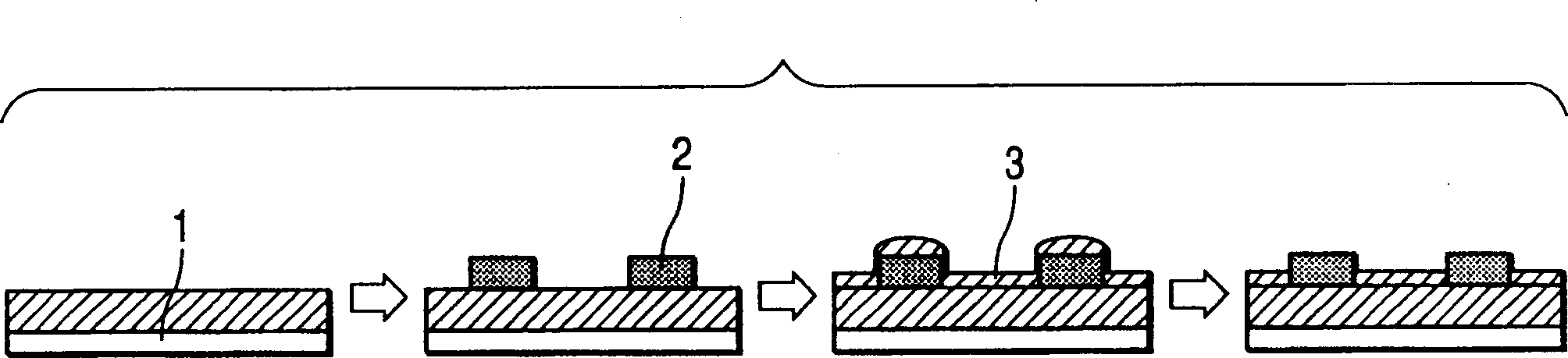

[0045] Such as figure 2 As shown, internal electrodes 2 having a predetermined thickness are formed on substrate 1 by an arbitrary process. The paste of the photosensitive ceramic 3 is then applied on the surface of the internal electrodes. The paste is dried so that its thickness is smaller than that of the internal electrodes just before exposure. Subsequently, after passing the Figure 4 While masking the internal electrode pattern with the photomask 4 shown, the photosensitive ceramic paste is irradiated with light from the upper side of the substrate for exposure. In this process, the surface of the photosensitive ceramic paste is selectively cured while controlling the exposure amount in such a manner that the exposed portion on the surface of the photosensitive ceramic paste is cured. Unexposed portions of the photosensitive ceramic paste are removed through a developing process to expose internal electrode patterns.

[0046] By stacking a plurality of photosensiti...

Embodiment 3

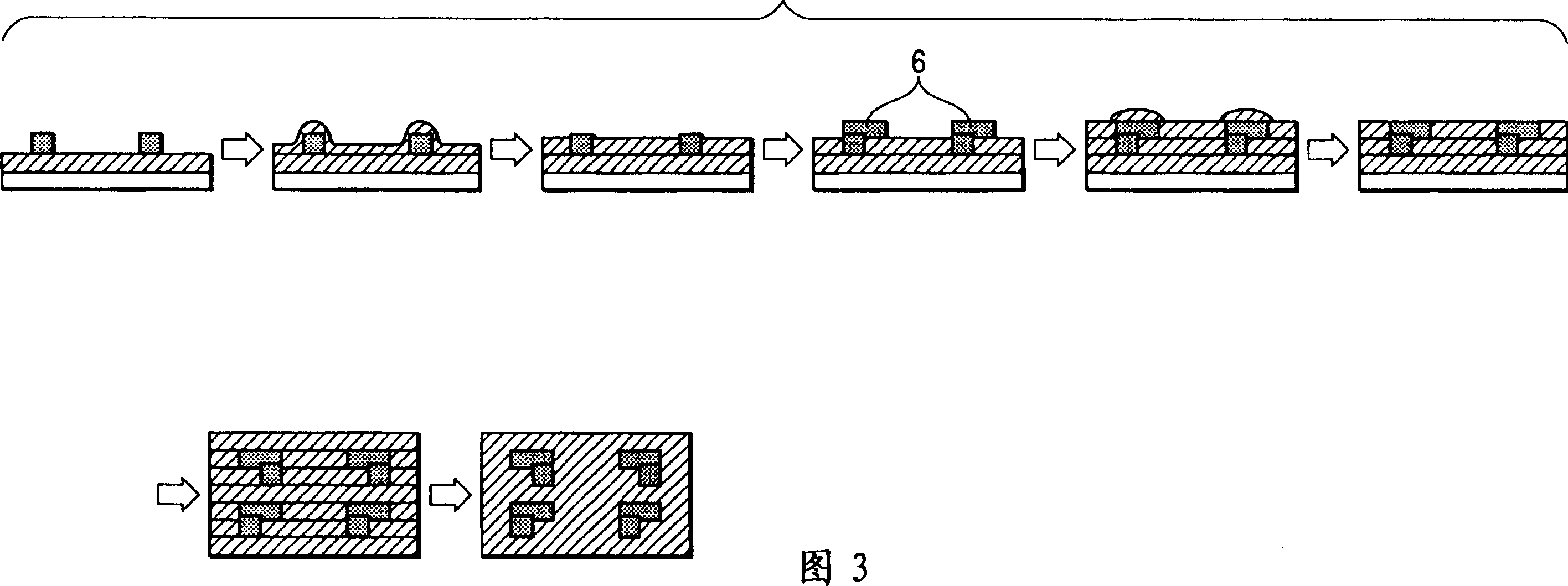

[0048] As shown in FIG. 3, an internal electrode 2 having a predetermined thickness is formed on a substrate 1 by an arbitrary process. The paste of the photosensitive ceramic 3 is then applied on the surface of the internal electrodes. The paste is dried so that its thickness is smaller than that of the internal electrodes just before exposure. Subsequently, after passing the Figure 4 While masking the internal electrode pattern with the photomask 4 shown, the photosensitive ceramic paste is irradiated with light from the upper side of the substrate for exposure. In this process, the surface of the photosensitive ceramic paste is selectively cured while controlling the exposure amount in such a manner that exposed portions on the surface of the photosensitive ceramic paste are cured. Unexposed portions of the photosensitive ceramic paste are removed through a developing process to expose internal electrode patterns. Pattern electrodes 6 are formed on the columnar electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com