Slider rolling-guiding device for press

A guide device and press technology, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problems of large guide rail clearance, easy wear and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

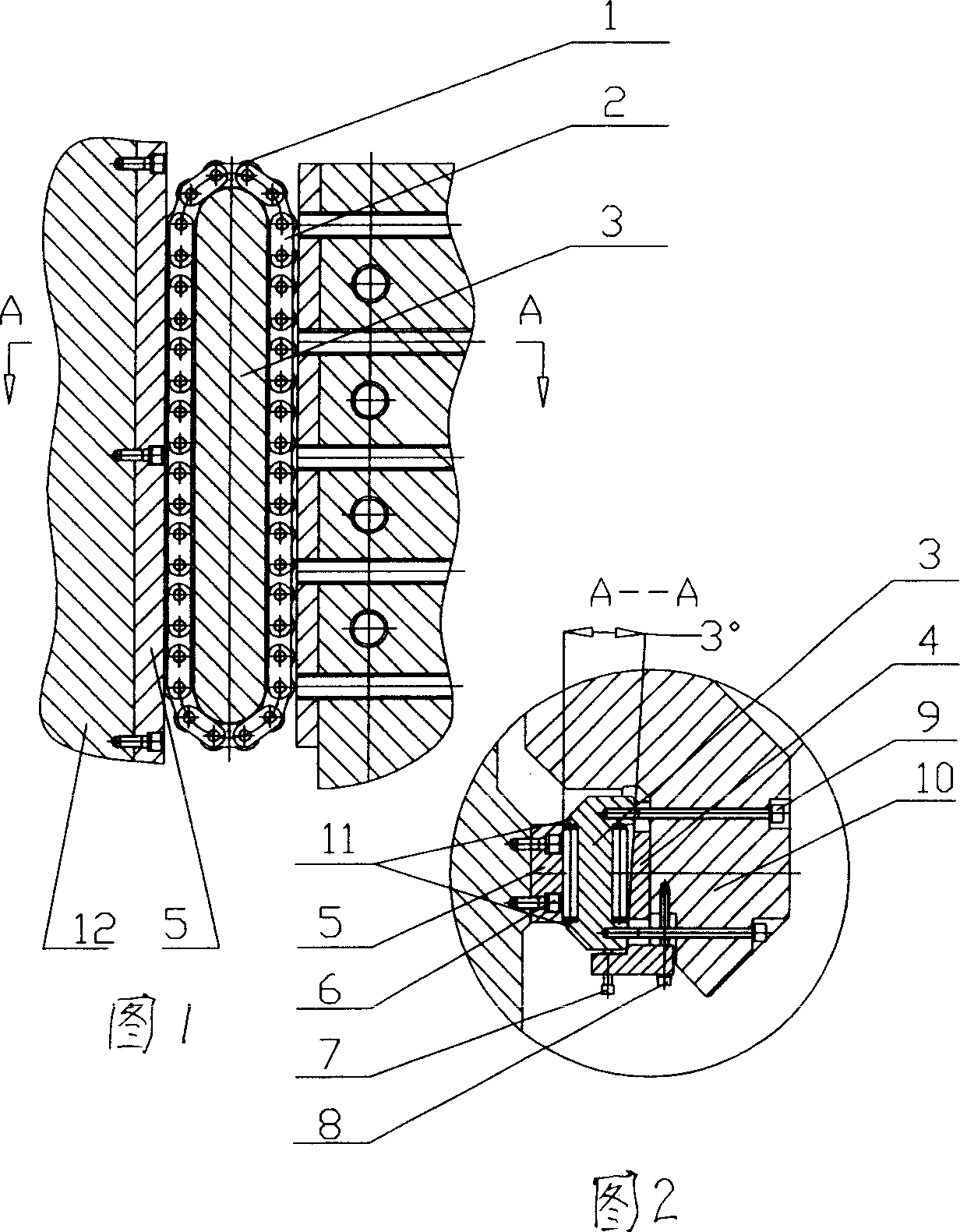

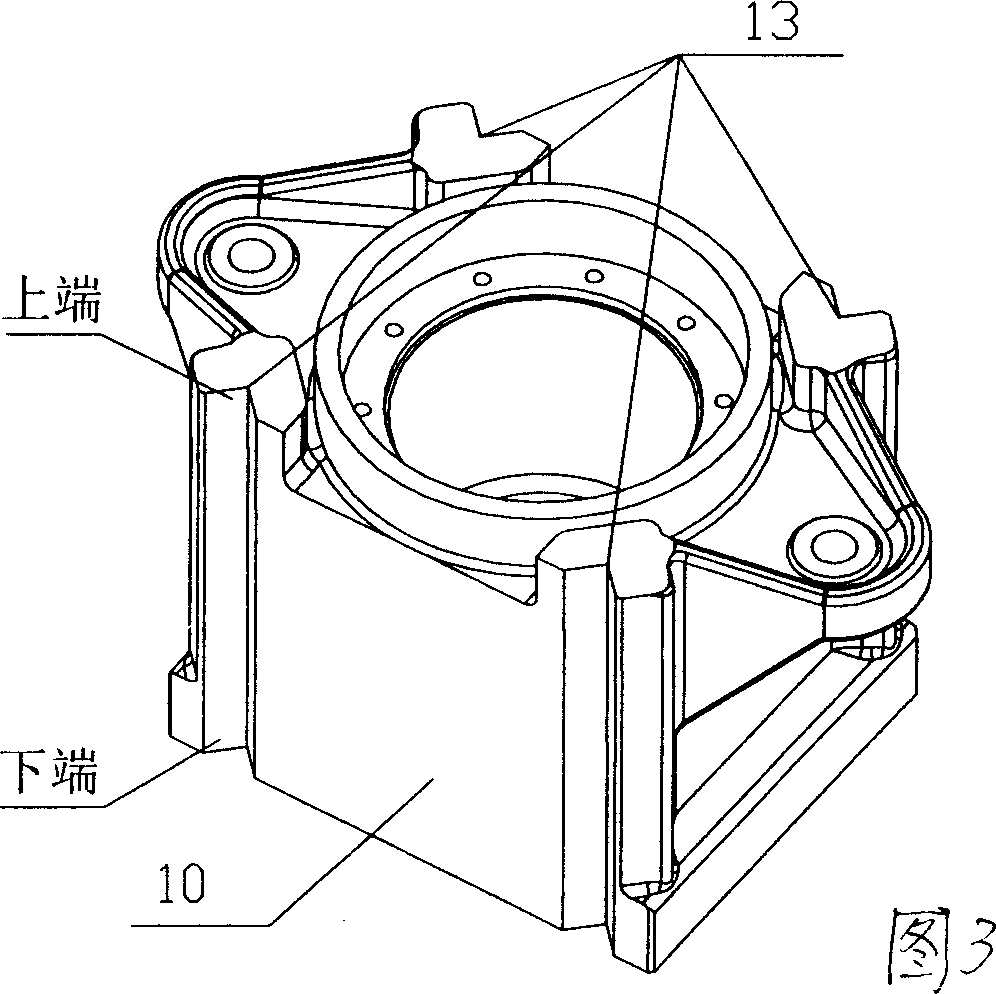

[0011] The rolling guide device of the slide block of the press, its structure and installation are as follows, a long endless chain is movably connected by a plurality of rollers 1 with small shafts at both ends and a hinge plate 1 with two holes, and is rolled and installed on the annular raceway On the body 3; the flanges 11 on both sides of the raceway body 3 block the hinge plate 2. There are grooves 13 on the four vertical sides of the slider 10, and the eight raceway bodies 3 are fixedly connected to the upper and lower ends of the groove of the slider through the adjusting plate 4 and bolts 9 respectively; The plate 5 is fixedly connected to the frame by the bolt 6; the angle between the mating surface of the raceway body 3 and the adjusting plate 4 and the track plane is 3-5°; The adjusting bolt 8 installed on the right boss fixes the adjusting plate on the slide block, and the adjusting bolt 7 installed on the left boss abuts on the raceway body 3 . When the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com