Circulating chain code calibration equipment lifting mechanism

A technology of circulating chain code and verification device, applied in the field of bulk material metering device, can solve the problems of long total length of equipment, consumption of manufacturing cost, large size of driving rod, etc. Reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

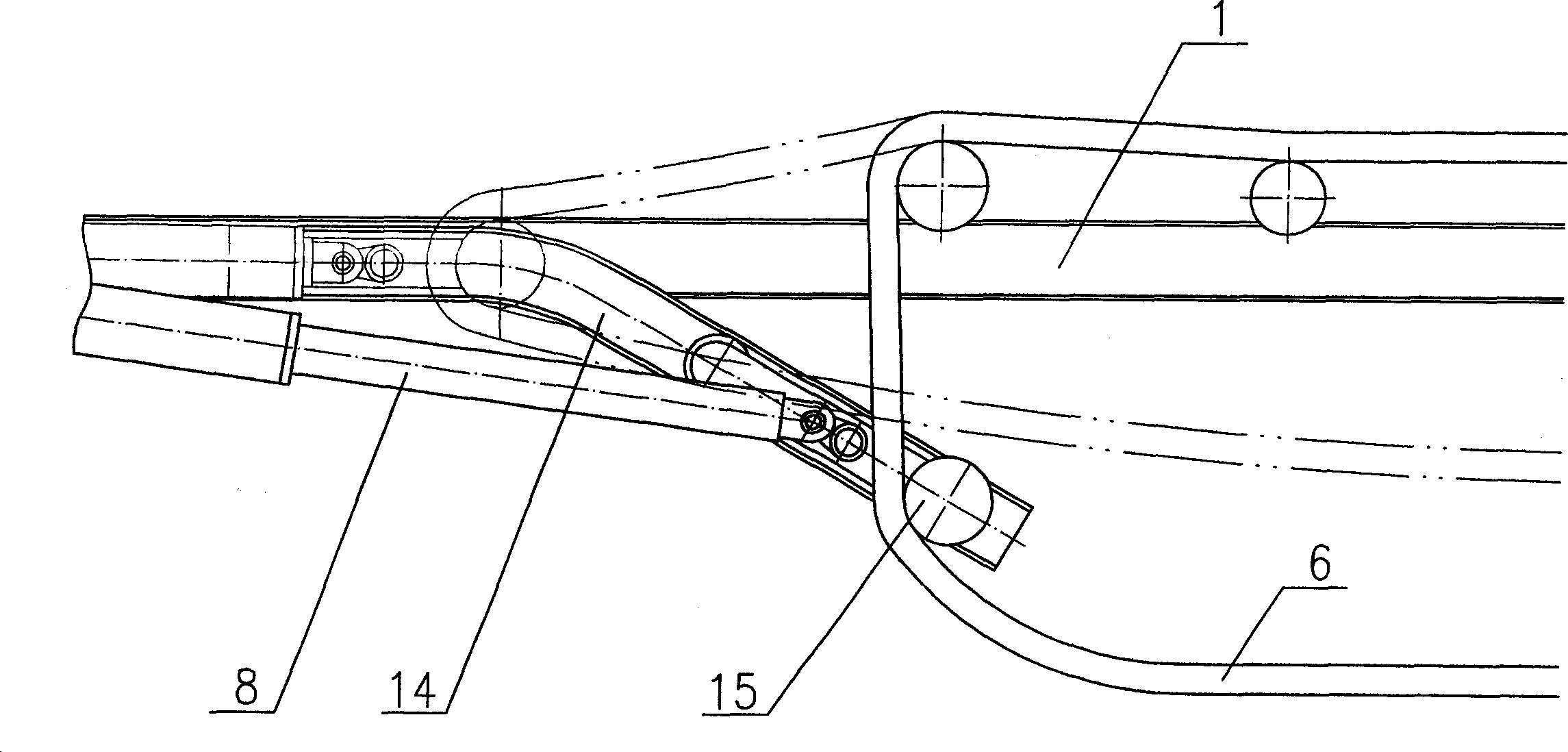

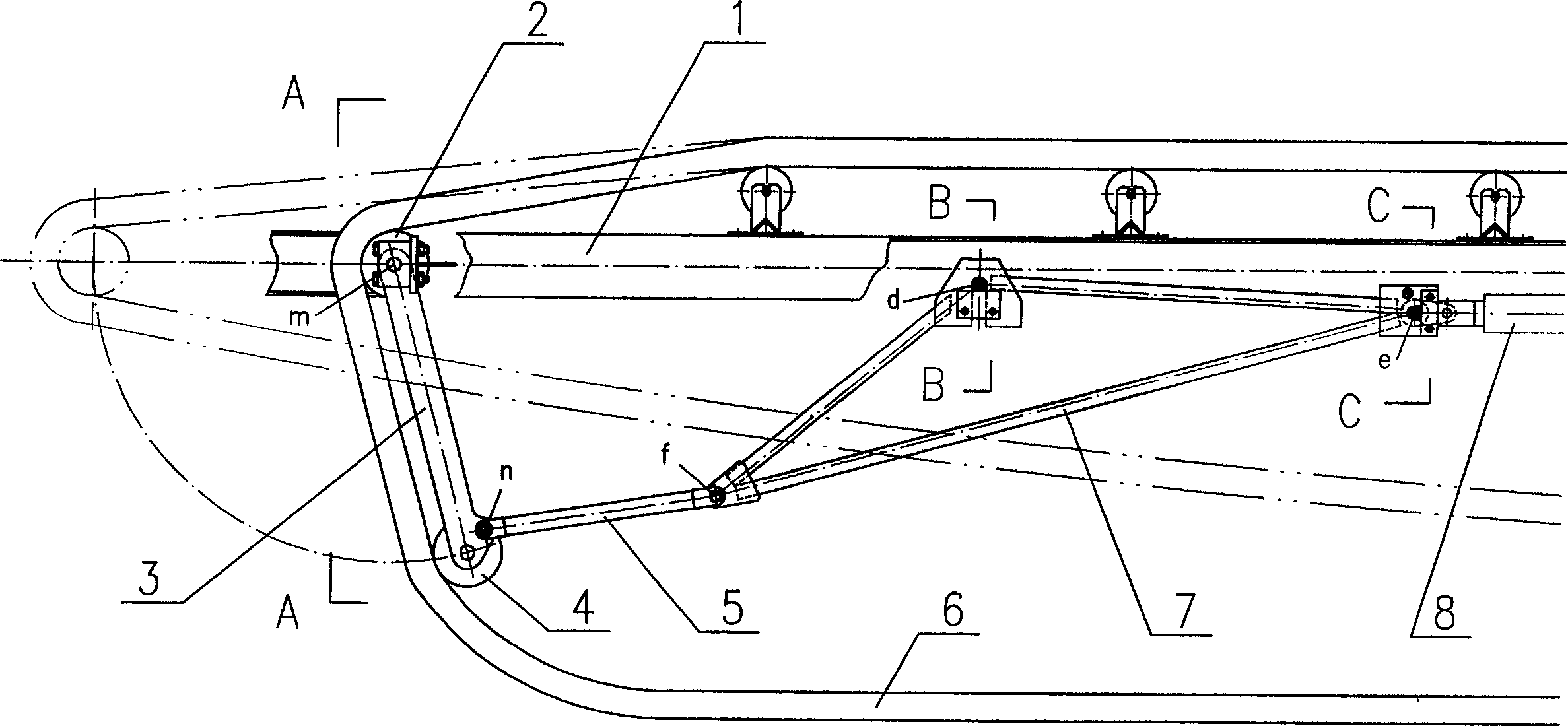

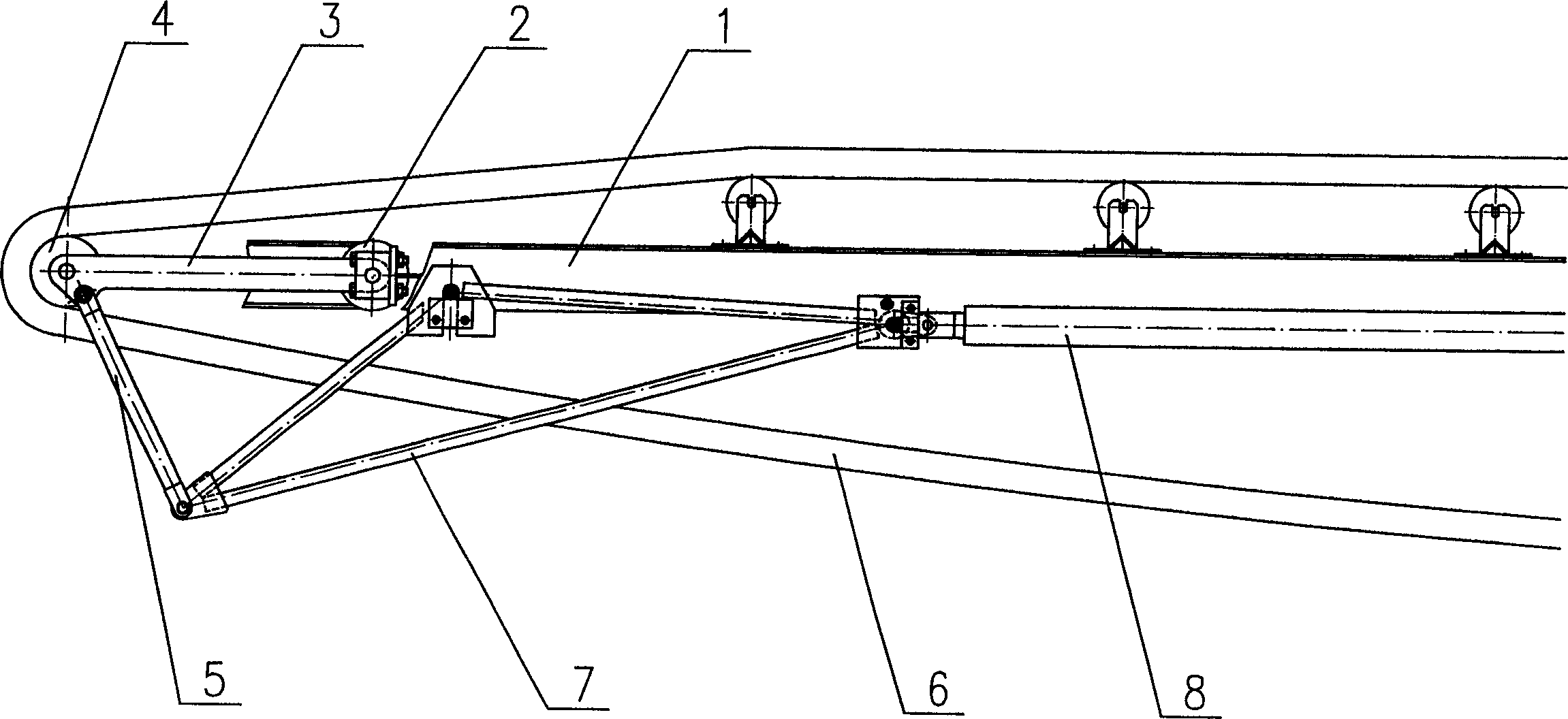

[0028] Such as figure 2 , image 3 As shown, the present invention is used for the lifting mechanism of the cyclic chain code verification device for electronic belt scale verification, including the frame main beam 1, the triangular vehicle frame 7, the cyclic chain code 6 and the driving rod 8, the triangular vehicle frame 7 and the driving rod 8 is located at the inner side of the circular chain code 6, the first end point d or the first and second end points d, e of the triangular vehicle frame 7 are installed on the frame main beam 1 and move left and right with the frame main beam 1 as a guide rail, and the second The end point e is connected with the drive rod 8, and the third end point of the triangular vehicle frame 7 protrudes downward to form a push point f; a swing rod 3 is arranged at one end of the main beam 1 of the frame, and the fixed end of the swing rod is connected with the main beam of the frame. 1 Hinged, the hinge axis is m, the swing end of the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com