Manufacturing method and manufacturing apparatus for image display device

An image display device and a manufacturing method technology, applied in the manufacture of discharge tubes/lamps, ships or lead-in wires, and cold cathode manufacturing, can solve the problems of increasing the withstand voltage to the desired value and achieve withstand voltage characteristics Excellent, display performance and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

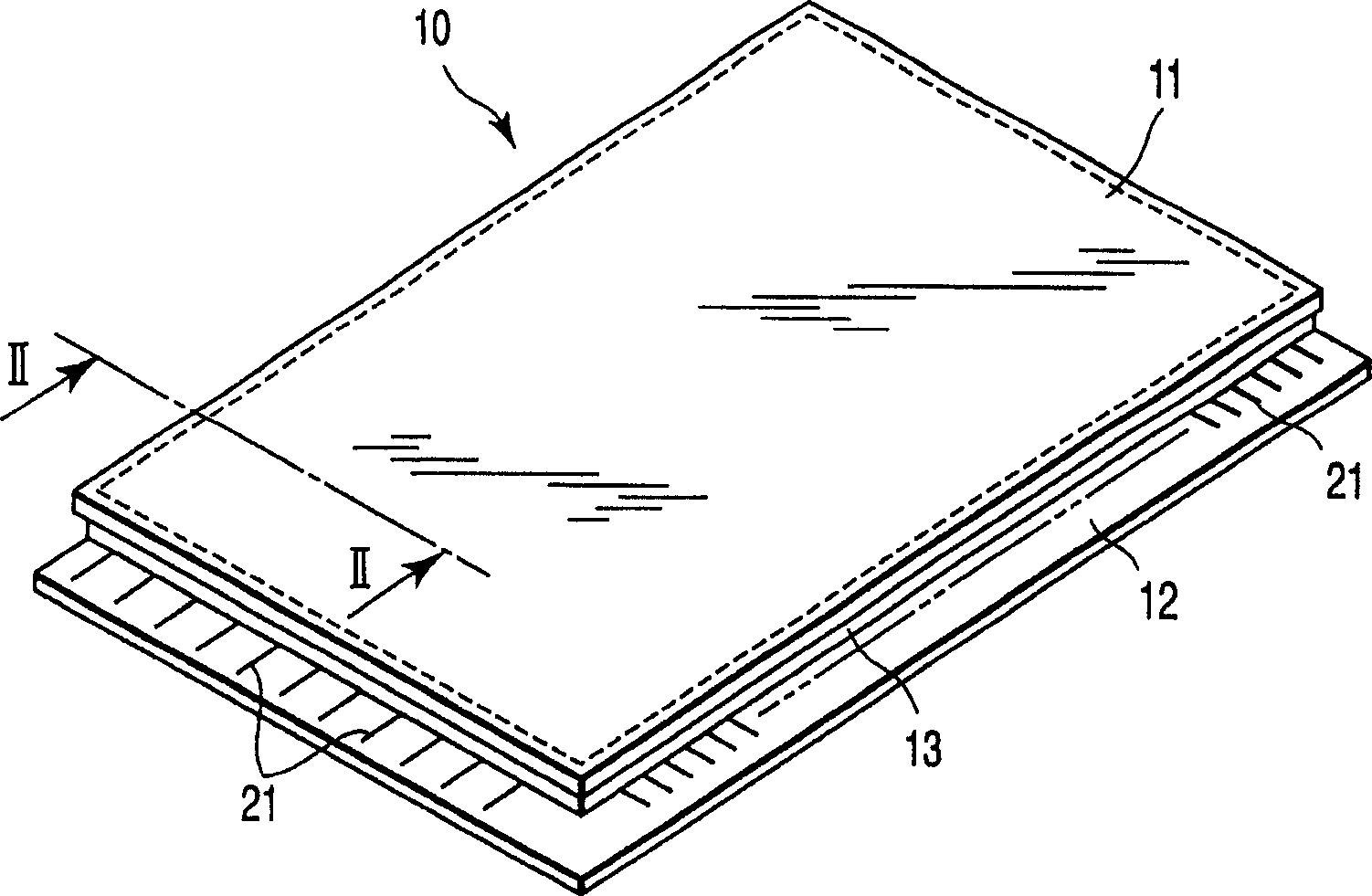

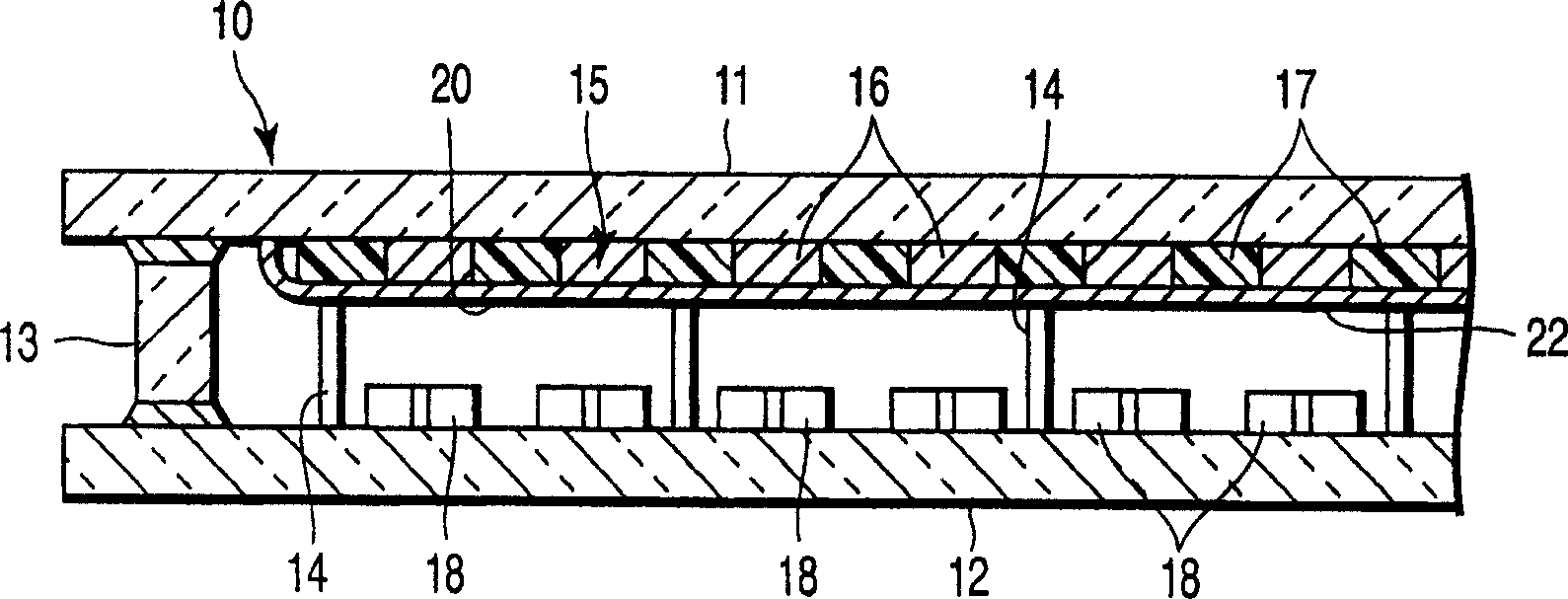

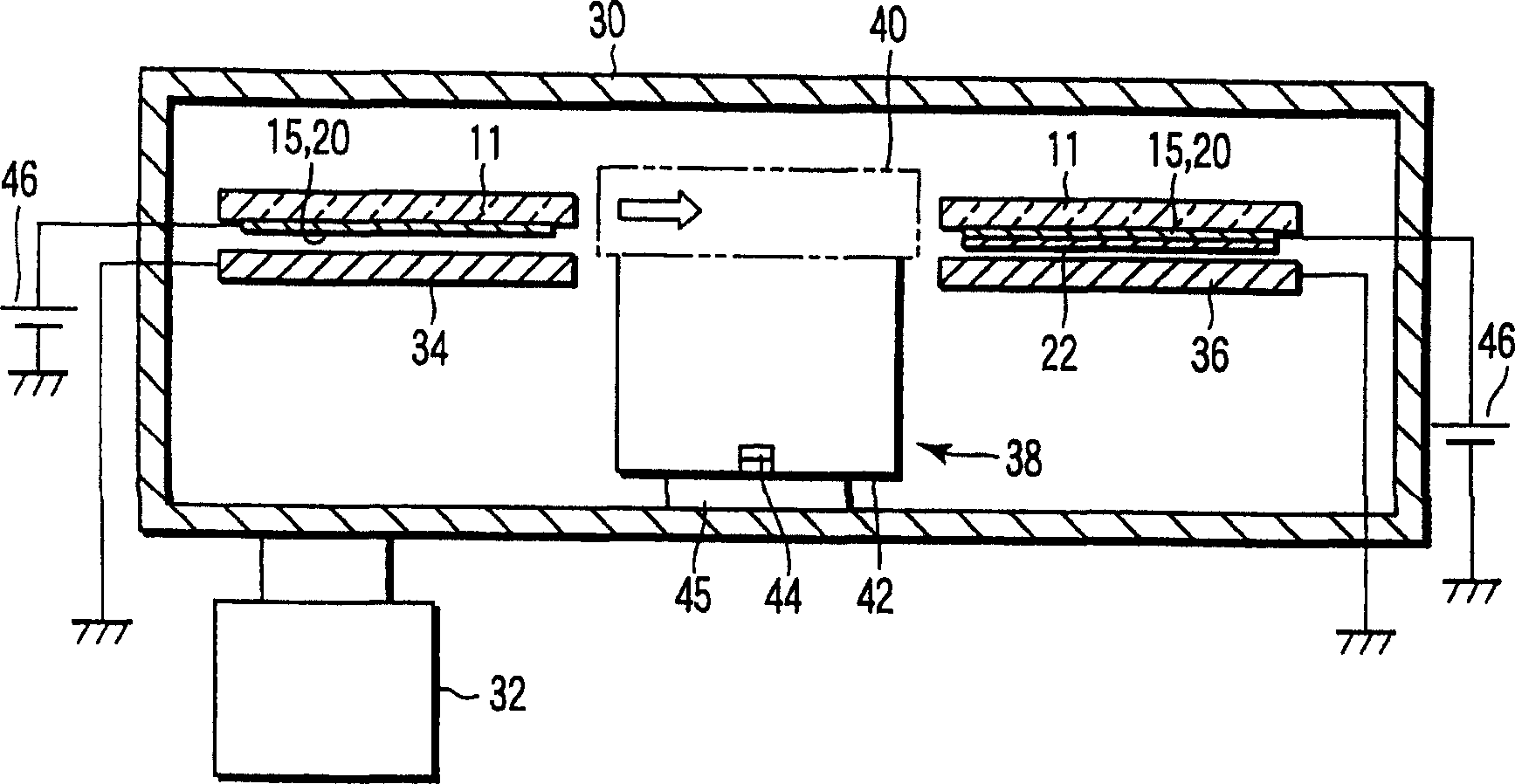

[0041] Hereinafter, a method of manufacturing an image display device and a manufacturing apparatus according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0042] First, as an image display device manufactured by the method and manufacturing apparatus of the present invention, an FED having a surface conduction type electron emission element will be described as an example.

[0043] Such as figure 1 and figure 2 As shown, this FED has, as an insulating substrate, a front substrate 11 and a rear substrate 12 each composed of a rectangular glass plate with a plate thickness of about 1 to 3 mm, and these substrates face each other with a gap of 1 to 2 mm. The front substrate 11 and the rear substrate 12 are connected to each other through the rectangular frame-shaped side wall 13 to form an internal support 10. -4 A flat rectangular vacuum envelope 10 of high vacuum around Pa.

[0044] A plurality of suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com