Glutamine transferase soy-bean protein fish and meat product and the like

A technology for transglutaminase and glutamine, applied in animal protein processing, plant protein processing, etc., can solve problems that are not known

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

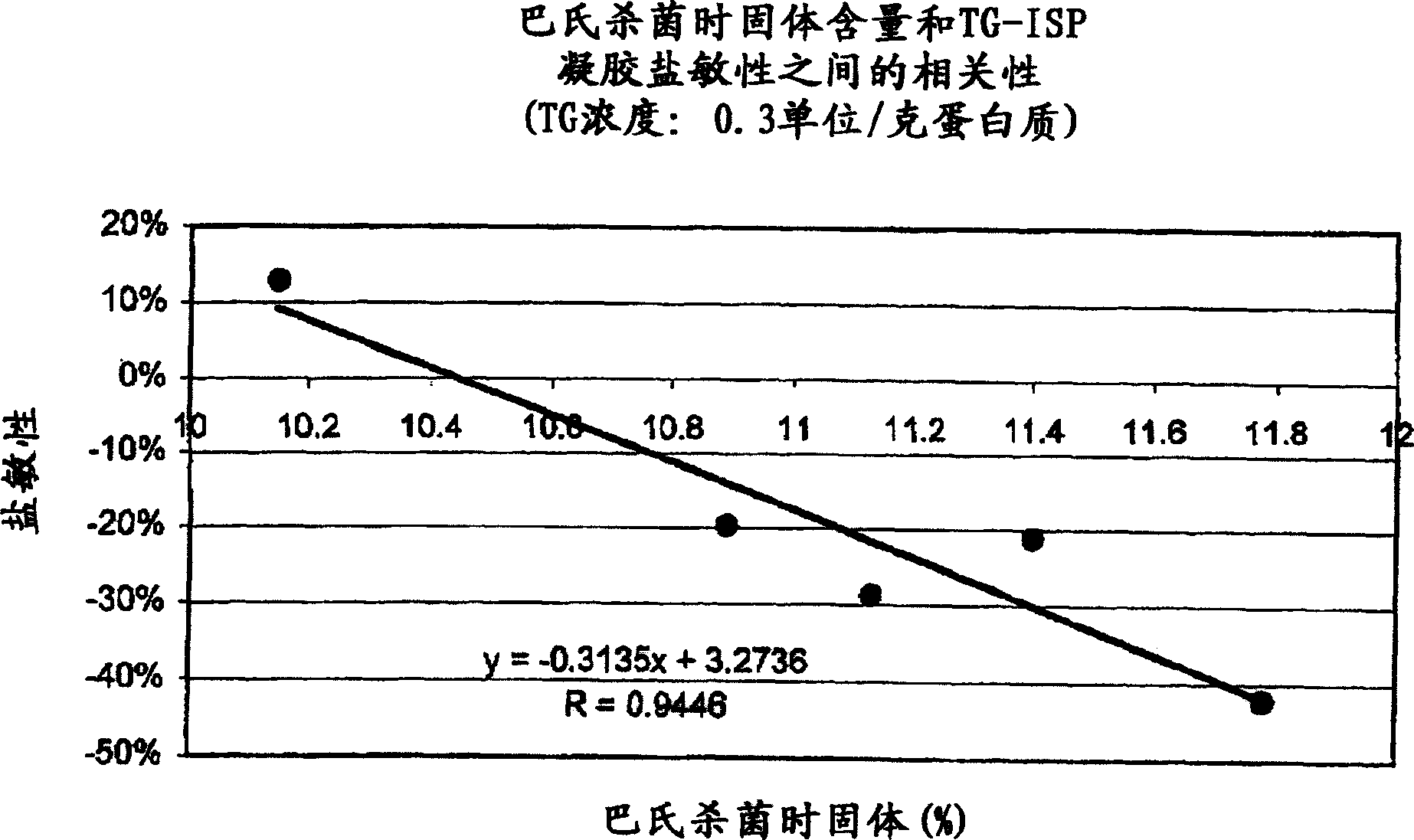

[0032] Transglutaminase-coupled soy protein was prepared using 0.3 units of transglutaminase per gram of protein for 30 minutes of coupling, 10.2% total solids pasteurization.

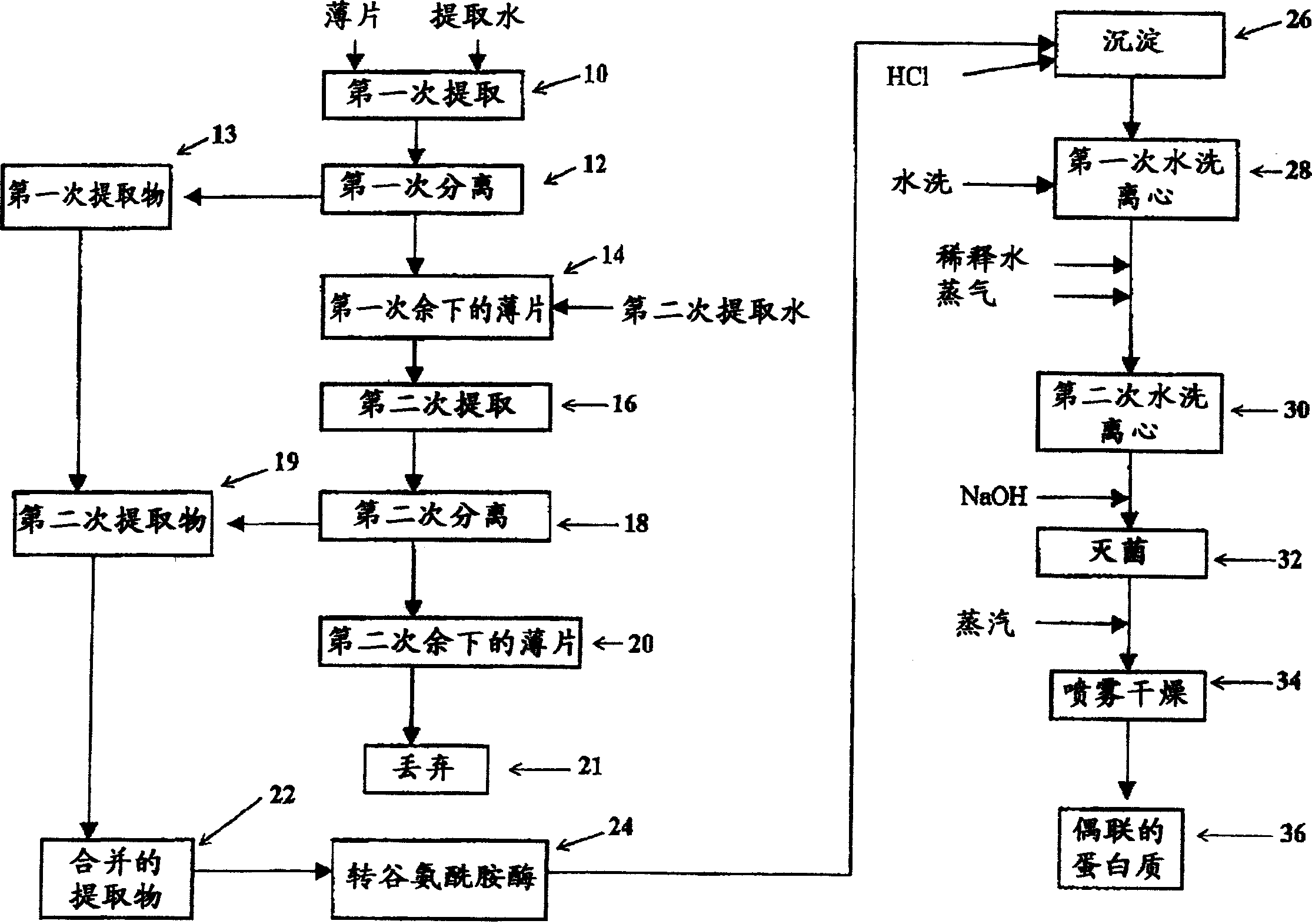

[0033] Extracts were prepared by a standard two-step co-current extraction process. Soybean powder and water at a ratio of 1 part powder to 10 parts water, into the first extraction of 10. The pH of the first extraction was not chemically adjusted. Total solids is 8.5% the first extraction slurry is pumped into the first separation 12 at a rate of 116 pounds per minute, at a cylinder speed (bowl speed) of 4000 RPM (revolutions per minute) pinion speed (pinion speed) is Separation in a 3000RPM centrifuge. The first extract 13 at 6.7% total solids was pumped into the combined extract flow line, while the first remaining flakes 14 at 21.4% total solids were reslurried with 60 lbs of water at 4.4% total solids at The second extract is formed in 16, pumped into 18. In 18, the second separation is carried...

Embodiment 2-5

[0036] Some minor changes were made, and the process of Example 1 was repeated, that is, the solid content during pasteurization in each example was as follows.

[0037] Example Solid

[0038] 2 10.9%

[0039] 3 11.4

[0040] 4 11.1

[0041] 5 11.8

Embodiment 6-10

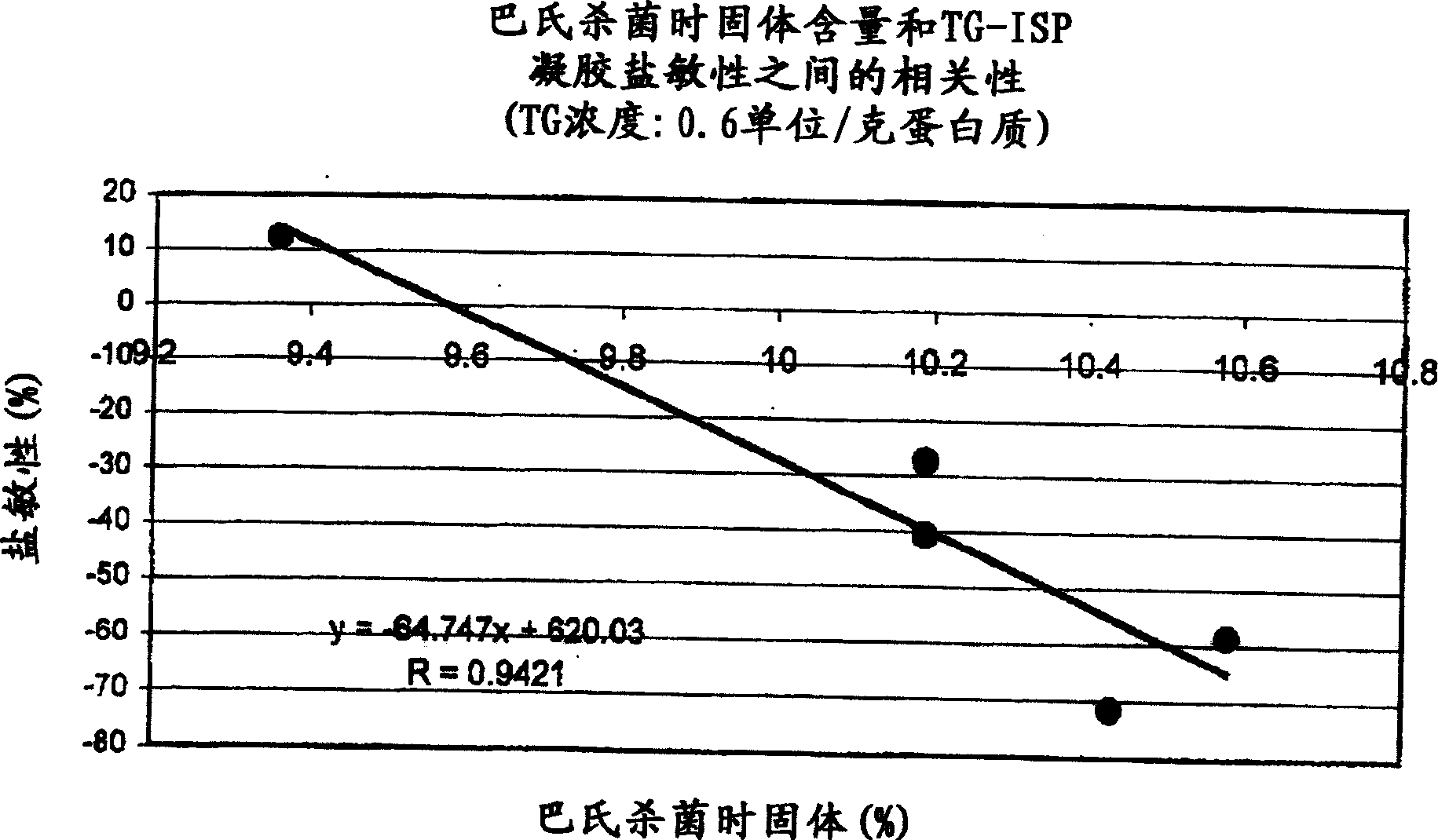

[0043] With some minor changes, the procedure of Example 1 was repeated, i.e. the concentration of transglutaminase was changed from 0.3 units of transglutaminase per gram of protein to 0.6 units of transglutaminase per gram of protein, and the various examples The solids content during medium pasteurization is shown below.

[0044] Example Solid

[0045] 6 9.4%

[0046] 7 10.1

[0047] 8 10.2

[0048] 9 10.6

[0049] 10 10.4

[0050] A correlation of gel strength in transglutaminase crosslinked vegetable proteins with and without added salt has been noted. This correlation is related to the amount of solids present when pasteurization is performed. Positive values for salt sensitivity are most desired, but negative values for salt sensitivity are acceptable as long as the negative value does not exceed -30%. "Controlled salt sensitivity" means a salt sensitivity of from -30% to 30%, most preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com