Sewing machine

A sewing machine and fan impeller technology, which is applied to sewing machine components, sewing equipment, sewing machine control devices, etc., can solve the problems of not being able to make full use of motor efficiency, stop the motor in advance, etc., and achieve effective guidance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

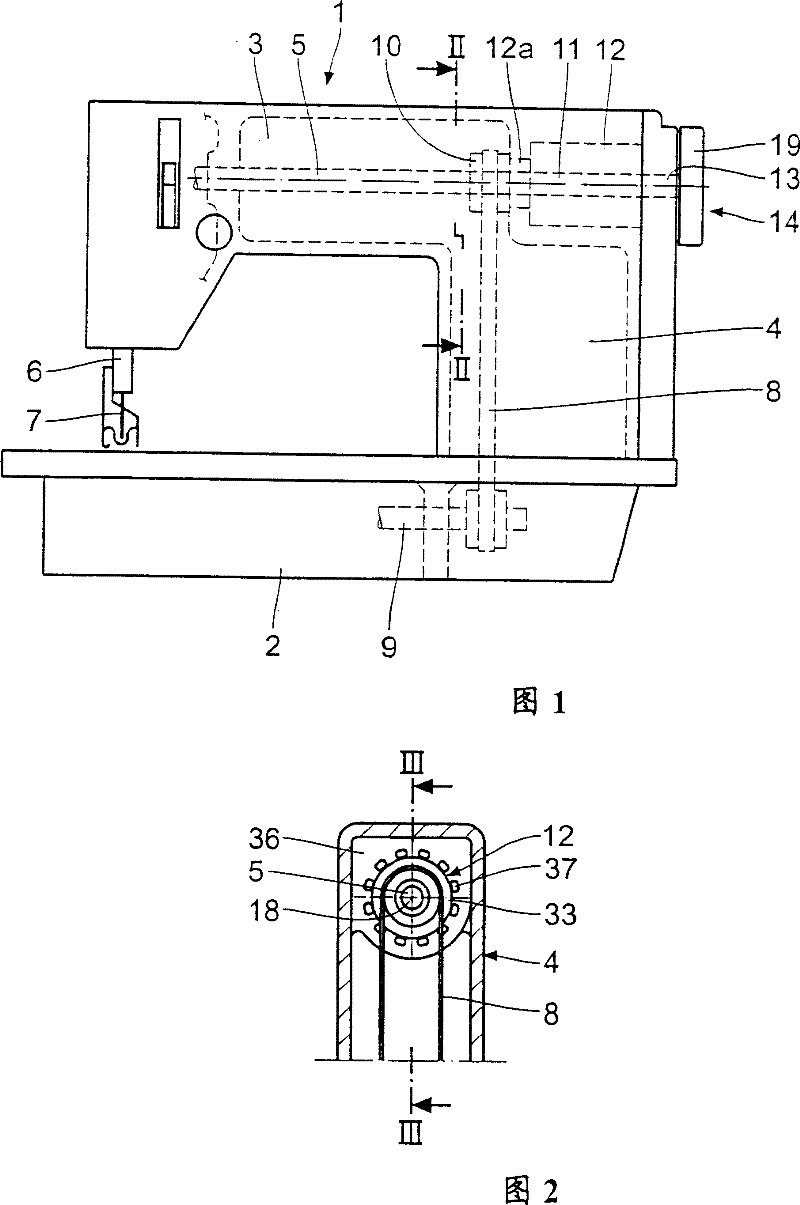

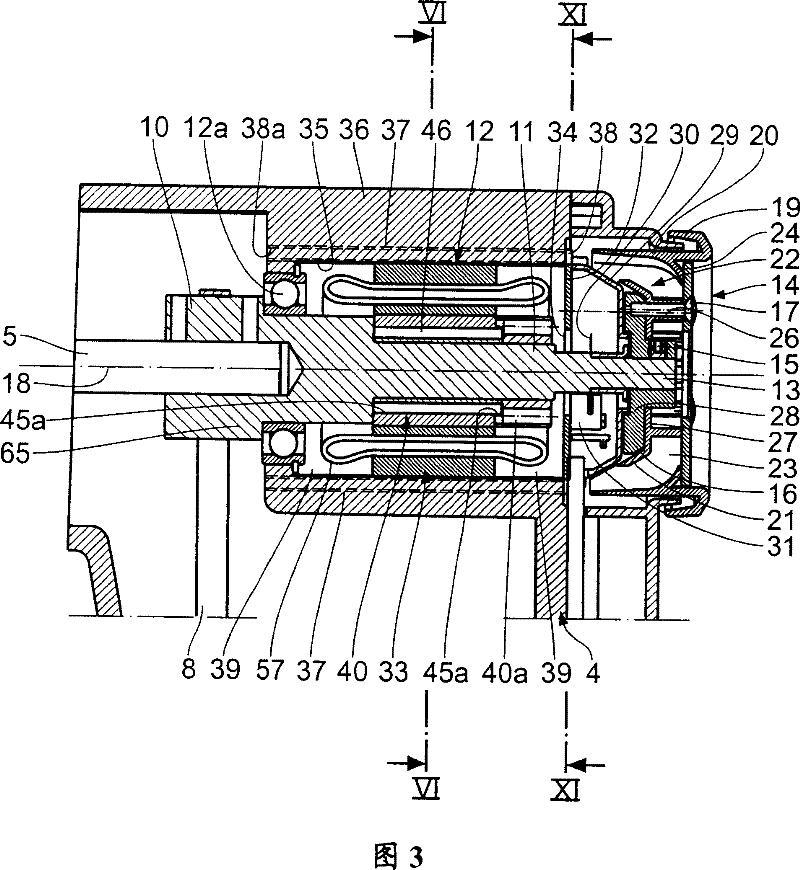

[0025] Figures 1 to 13 The sewing machine 1 shown in the figure comprises a base plate 2 in the form of a housing, a top arm 3 and a column 4 connecting the two parts. That is, the overall shape of the sewing machine 1 is roughly C-shaped. An arm shaft 5 is supported in the top arm 3, through which a needle bar 6 with a needle 7 is driven to reciprocate up and down by means of a crank driver (not shown). The arm shaft 5 drives via a (belt) belt drive 8 and a shaft 9 mounted in the base plate 2 a thread hook, also not shown, which is mounted in the base plate 2 and assigned to the needle 7 .

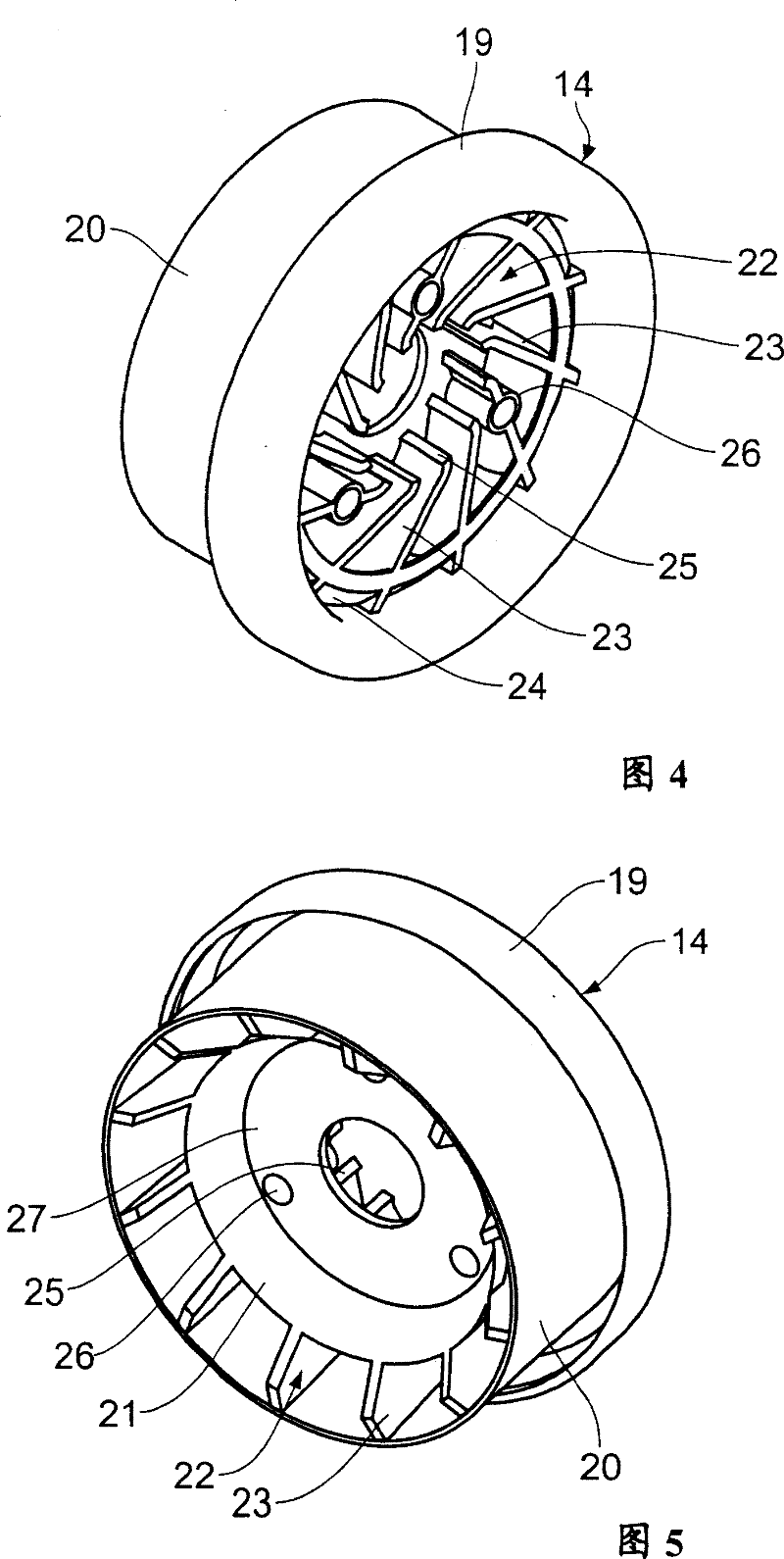

[0026] A flange portion 10 is provided on the arm shaft 5 at the level of the belt drive 8 . The arm shaft 5 is relatively non-rotatably coupled via a flange portion 10 to a drive shaft 11 of an arm shaft drive motor 12 aligned with the arm shaft. The drive shaft 11 is supported by an axial / radial bearing 12a at a position adjacent to the flange portion 10 . A hand wheel 14 is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com