Electromagnetic coil of step-by-step motor of electric valve

A technology of stepping motor and electromagnetic coil, applied in the direction of electric components, valve operation/release device, valve device, etc., can solve the problems of labor-hour and cost, increase cost, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

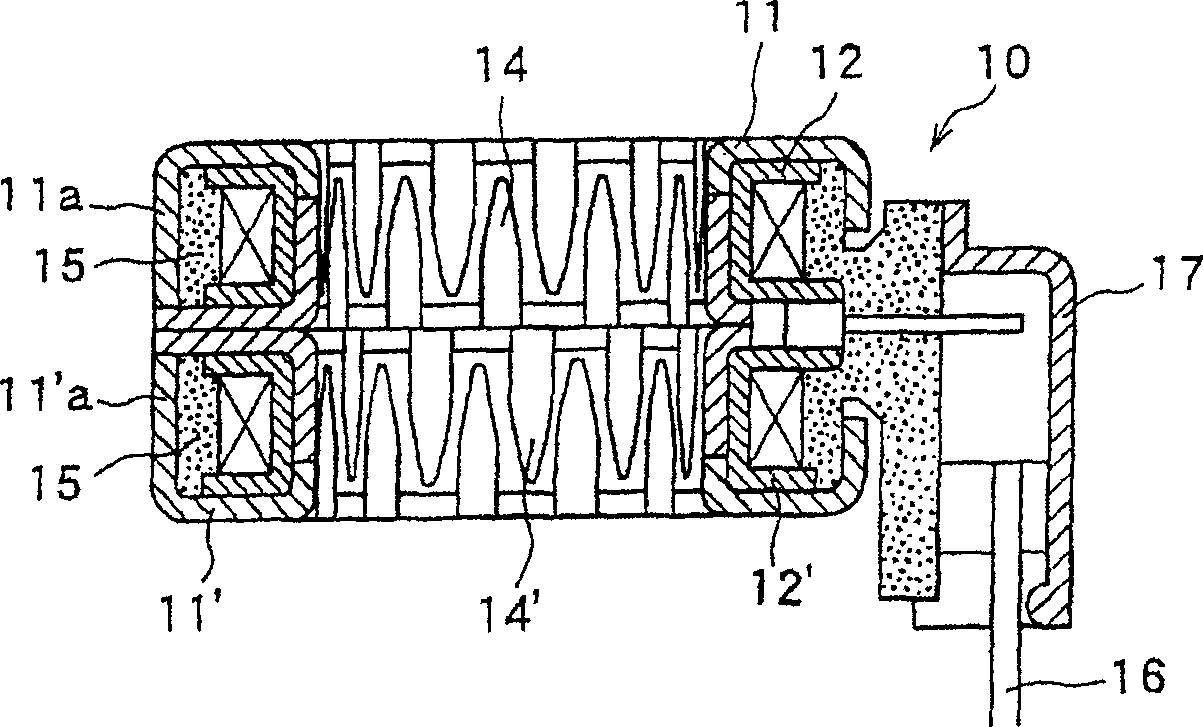

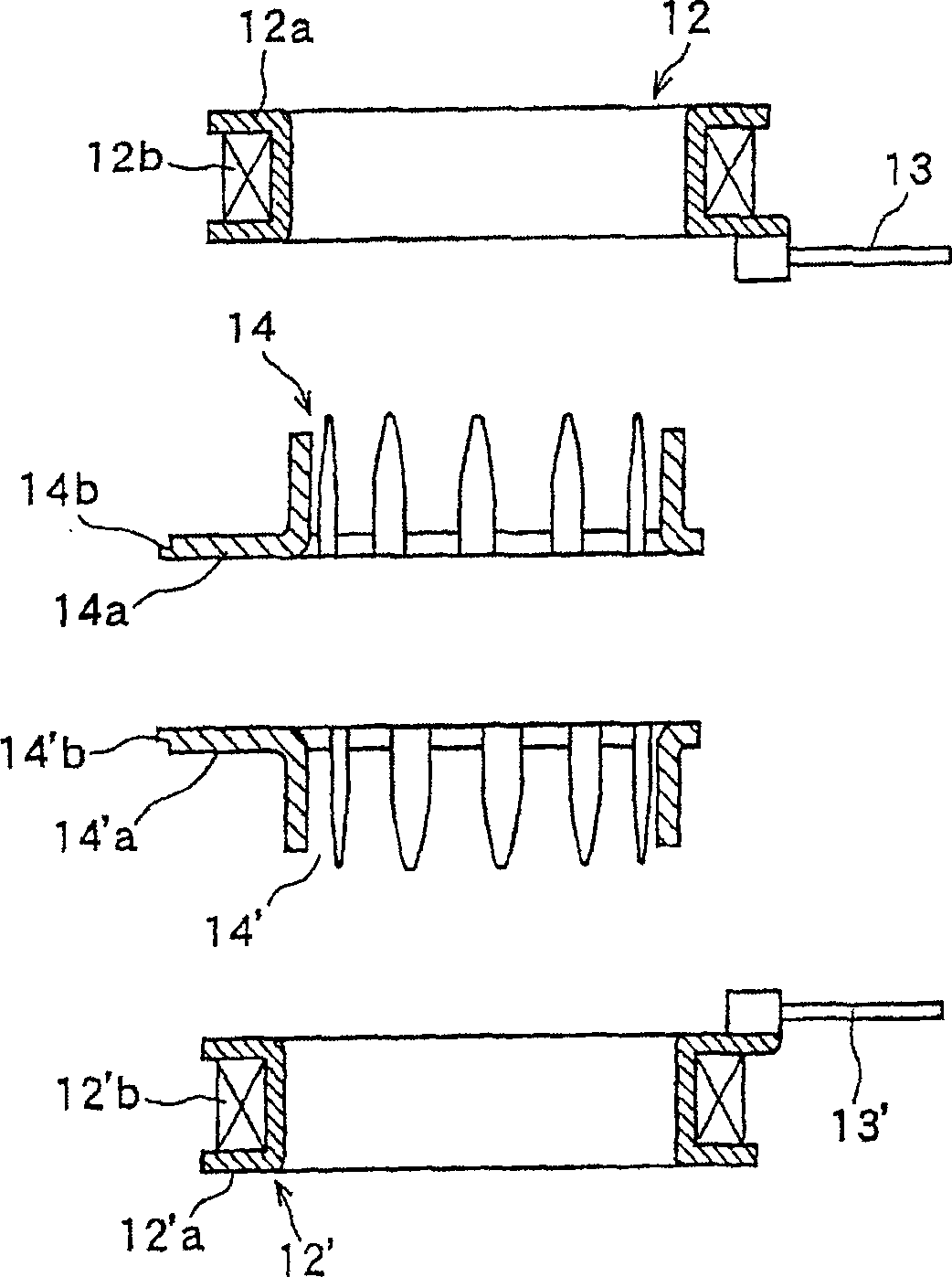

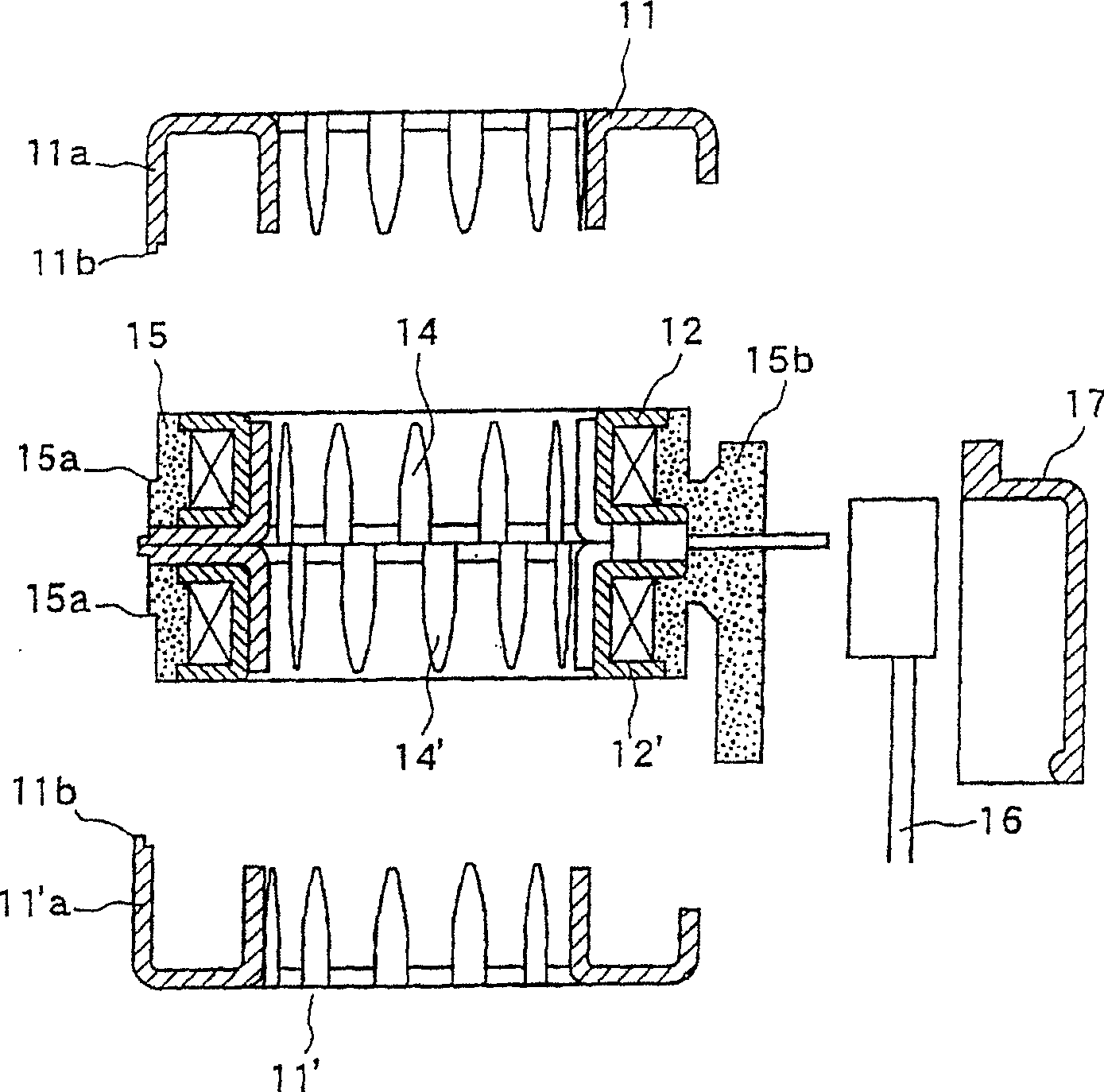

[0033] Embodiment 1 will be described with reference to the drawings. figure 1 is a longitudinal sectional view of the electromagnetic coil, figure 2 It is a cross-sectional view showing the first stage of the assembly process of the same electromagnetic coil, image 3 is a sectional view showing the second stage, Figure 4 It is an explanatory diagram showing important parts of the same assembly process.

[0034] The electromagnetic coil 10 of the stepping motor, such as figure 1 As shown, by winding the first coil 12b on the first bobbin main body 12a, and covering the outer peripheral portion of the first coil 12b with the resin molded part 15, the first bobbin part 12 is formed on the second bobbin main body 12 The second coil 12'b is wound on the 'a, and the second coil frame part 12' which covers the outer peripheral part of the second coil 12'b with the resin molded part 15 is sandwiched between the first coil frame part 12 and the second coil frame part 12'. The...

Embodiment 2

[0043] Hereinafter, Embodiment 2 will be described with reference to the drawings. Figure 5 is a longitudinal sectional view of the electromagnetic coil, Image 6 is a cross-sectional view showing the first stage of the assembly process of the electromagnetic coil, Figure 7 It is a sectional view showing the second stage of the same assembly process, Figure 8 It is an explanatory diagram showing important parts of the same assembly process, Figure 9 It is a plan view of the electromagnetic coil of Example 2.

[0044] The electromagnetic coil 20 of the stepping motor is as Figure 5 As shown, by winding the first coil 22b on the first bobbin main body 22a and covering the outer peripheral portion of the first coil 22b with the resin molded part 25, the second bobbin main body 22 The second coil 22'b is wound on the 'a, and the second coil frame part 22' which covers the outer peripheral part of the second coil 22'b with the resin molded part 25 is sandwiched between the...

Embodiment 3

[0052] Hereinafter, Embodiment 3 will be described with reference to the drawings. Figure 10 It is a longitudinal sectional view of the electromagnetic coil of this embodiment 3, Figure 11 is a cross-sectional view showing the first stage of the assembly process of the electromagnetic coil, Figure 12 It is a sectional view showing the second stage, and FIG. 13 is a plan view of the electromagnetic coil of Embodiment 3, Figure 14 It is an explanatory diagram showing important parts of the same assembly process.

[0053] The electromagnetic coil 30 of the stepping motor is as Figure 10 As shown, by winding the first coil 32b on the first coil body 32a and covering the outer peripheral portion of the first coil 32b with the resin molded part 35, the second coil body 32 The second coil 32'b is wound on 'a, and the second bobbin part 32' which covers the outer peripheral part of the second coil 32'b with the resin molded part 35 is sandwiched between the first coil bobbin p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com