Buckle type assembled LED lamp structure

An LED lamp structure and snap-on technology, which is applied in the parts of lighting devices, lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of extremely high precision of production lines, difficult to meet the requirements of assembly process, etc., and achieve simplification. Assembly structure and installation process, easy mass production, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

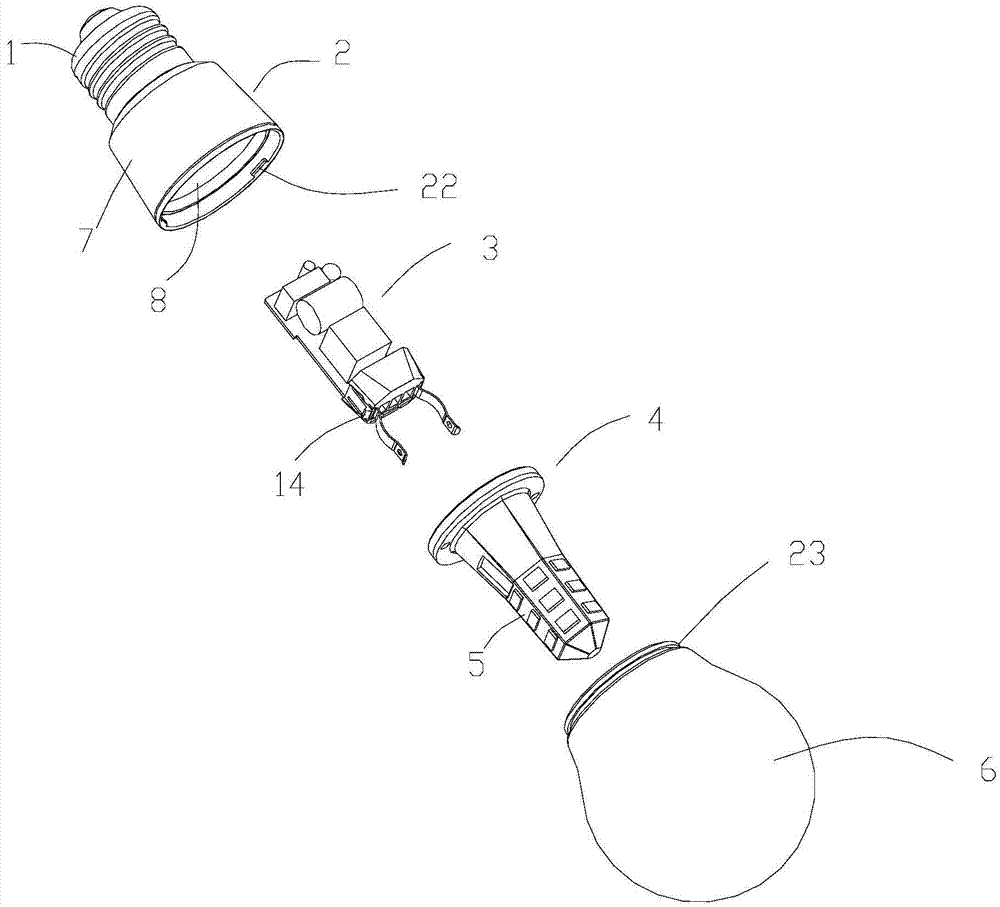

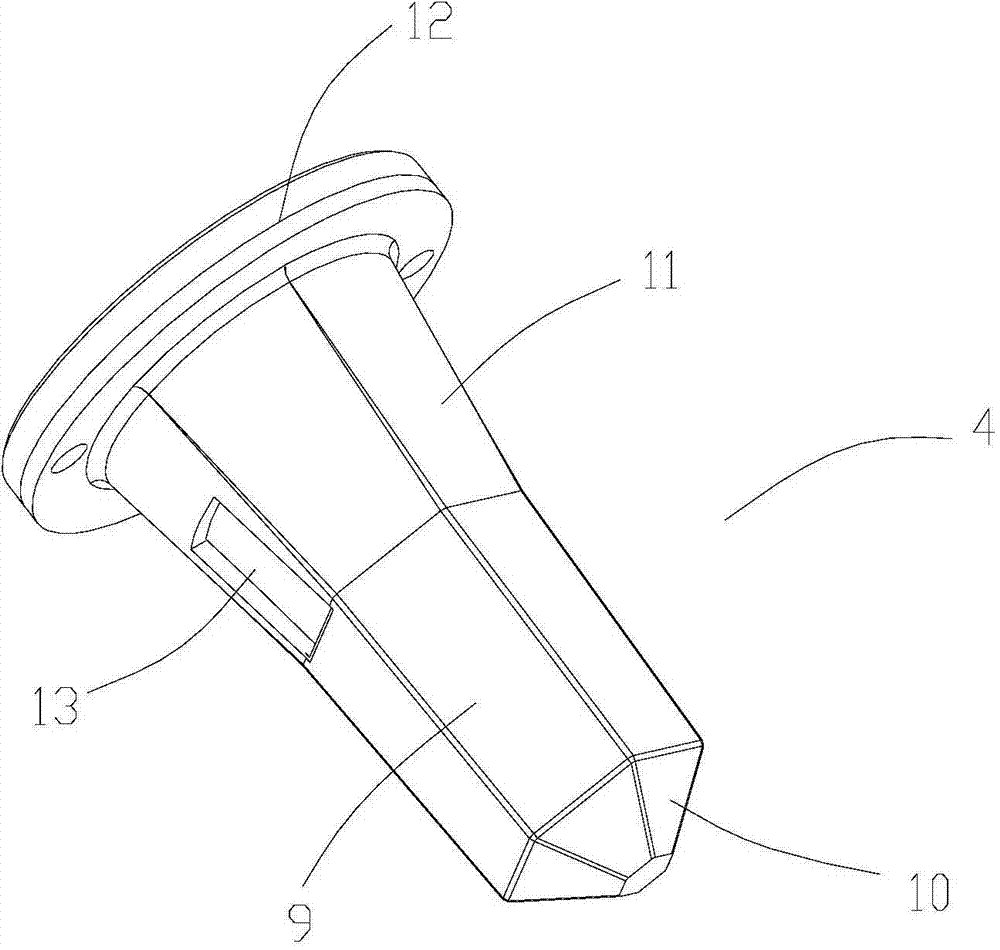

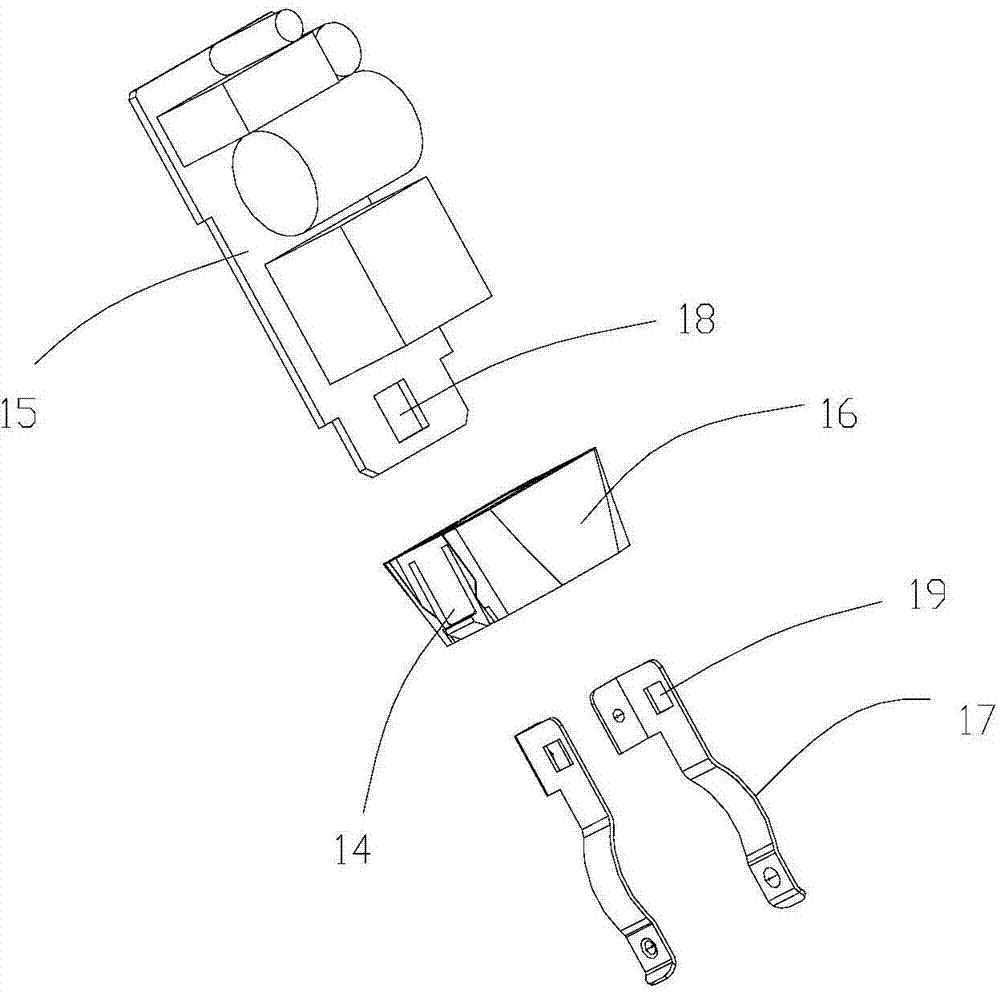

[0036] see figure 1 with figure 2 , this embodiment discloses a buckle-type assembled LED lamp structure, including a conductor 1, a heat dissipation lamp body 2, an electrical component 3, a heat conduction columnar body 4, a flexible light source plate 5 and a lampshade 6; the conductor 1 is installed on a heat dissipation The end of the lamp body 2; the electrical component 3 is electrically connected to the conductor 1, and the first buckle teeth 14 are provided on both sides of the electrical component 3; the heat-conducting columnar body 4 includes a columnar body 9 in the shape of a hollow prism, and the columnar body body 9. One end facing away from the heat dissipation lamp body 2 is provided with a pyramid-shaped cone head 10, and one end of the columnar body body 9 facing the heat dissipation lamp body 2 is provided with a transition portion 11 extending from a conical surface, and the end of the transition portion 11 is provided with a skirt. part 12, two first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com