Hanging film hollow glass and manufacturing method thereof

A production method and glass technology, applied in parallel glass structures, buildings, building components, etc., can solve problems such as low production efficiency, unstable quality, and difficult production and processing, so as to improve production efficiency and product quality, and simplify the structure and production process, the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

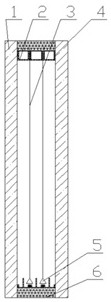

[0039] Example 1: Reference figure 1 , a two-glass three-cavity hanging film hollow glass, including glass 1, spacer frame 2, hanging film 3, sealant 4, bottom bar 5 and structural glue 6, glass 1 includes two pieces of glass at the front and back, between the two pieces of glass 1 A spacer frame 2 is bonded and fixed at the corresponding positions around the periphery by sealant 4. The sealant 4 generally adopts butyl glue, and a suspension film 3 is bonded and fixed by sealant 4 at the upper ends of the two spacer frames 2, and a spacer frame 2 is passed through a spacer. Frame 2 is bonded and pressed together, so that the two suspension films 3 are suspended in the cavity between the two pieces of glass 1, and a hollow cavity is formed between the suspension film 3 and the glass 1, and between the suspension film 3 and the suspension film 3, and the two The lower ends of the suspension film 3 are each fixedly connected with a bottom bar 5, and the suspension film 3 is tight...

Embodiment 2

[0040] Example 2: Reference figure 2 , a kind of two-glass two-cavity suspended film hollow glass, including glass 1, spacer frame 2, suspended film 3, sealant 4, bottom bar 5 and structural glue 6, are basically the same as embodiment 1, and its difference is that there is only one A hanging film 3 forms two hollow cavities with two pieces of glass 1, and becomes a hanging film hollow glass with two glasses and two cavities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com