Economical and practical micro DC air pump motor for automobile

A practical and automotive technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of difficulty in guaranteeing working reliability and working life, affecting the working reliability of products, frequent replacement, etc., to ensure long-term working stability and safety. Reliability, shortening and reducing product length and volume, simplifying product structure and the effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

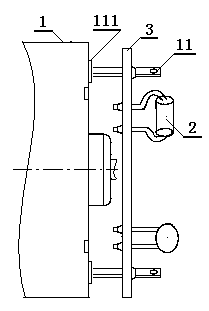

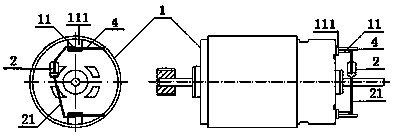

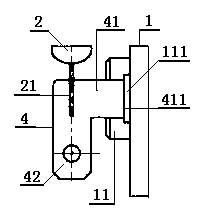

[0015] exist figure 1 Among them, the motor body of the currently commercially available micro DC air pump motor for automobiles related to the present invention includes a motor 1 with a power supply lug 11 extending from the upper limit of the end cover base 111 and a filter capacitor attached to the outer surface of the motor 1 For the special electric circuit board 3 of 2, the extra filter capacitor 2 is fixedly arranged on the special electric circuit board 3 by conventional soldering process, and the special electric circuit board 3 is fixedly welded and arranged on the power supply lug limited by the base 111 11 on. Working in the harsh environment of relatively high temperature and frequent vibration on the car for a long time, the solder joints are easy to age, loosen, or even fall off, which will affect the reliability of the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com