Debugging-free magnetic latching relay

A technology of magnetic latching relays and magnetizers, which is applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve problems that affect the reliability of relays, difficult production processes, complex relay structures, etc., and achieve simplified structures and production processes. The effect of reducing production costs and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

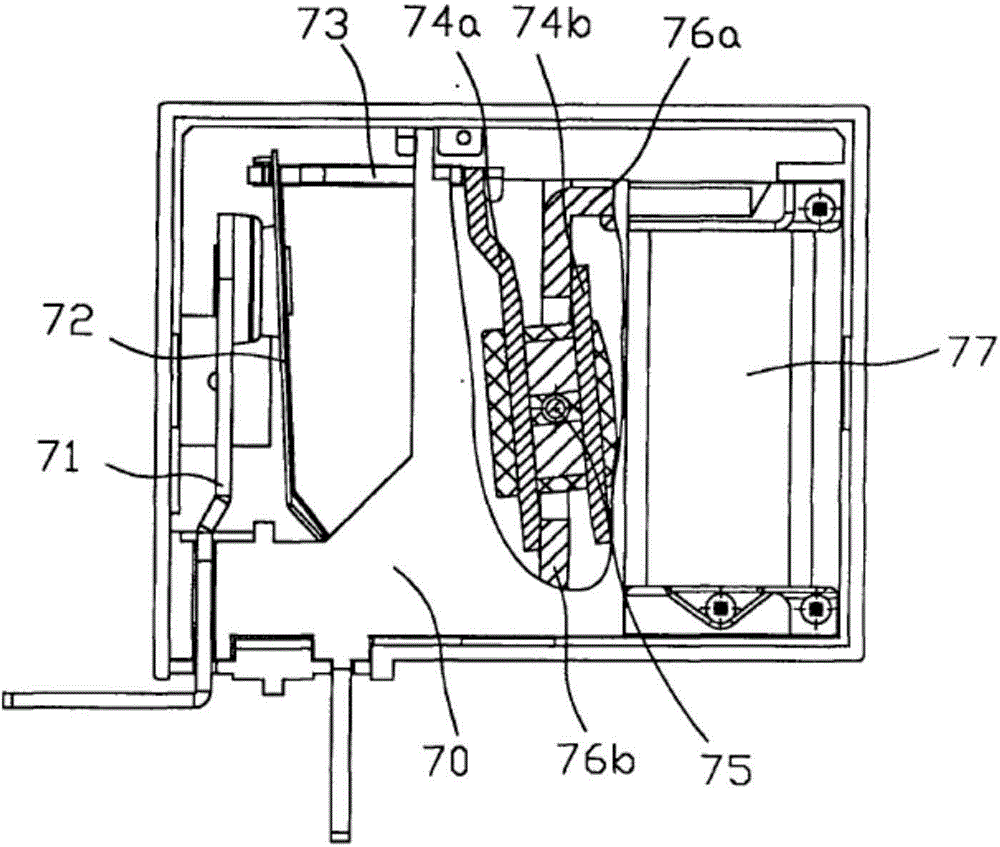

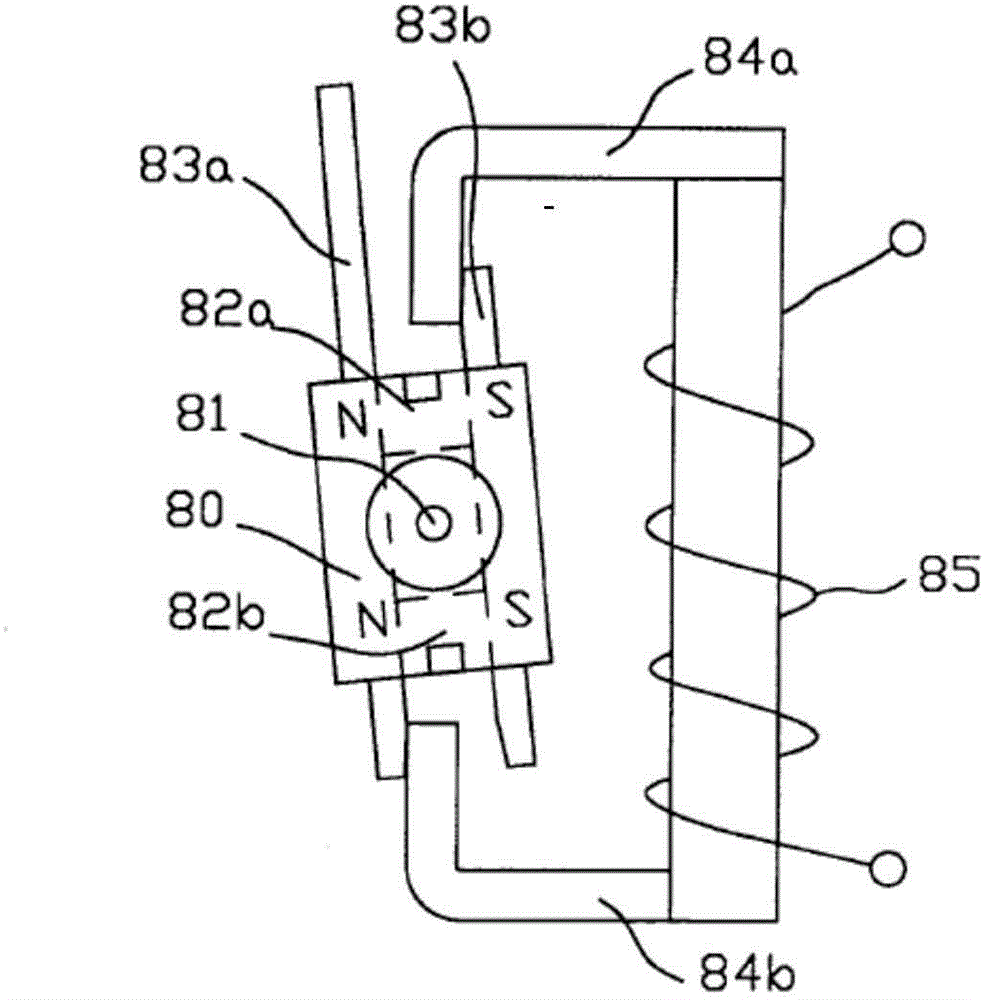

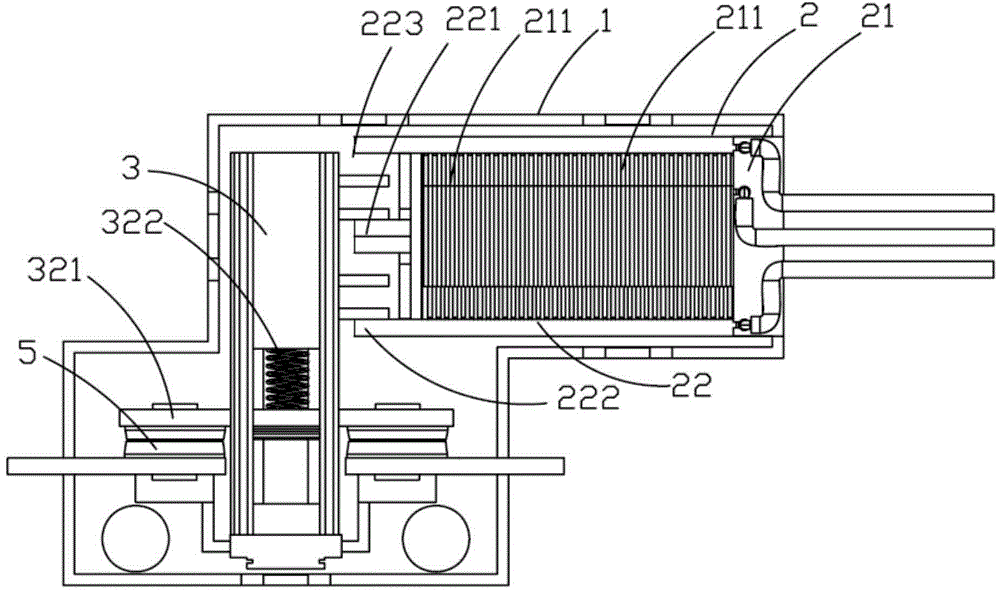

[0030] Please also refer to Figure 3 to Figure 11 , a debugging-free magnetic latching relay 9 according to the present invention includes a lower housing 1, a magnetic drive module 2, a bridge dynamic module 3 and an upper cover 4, and the magnetic drive module 2 drives the bridge dynamic module 3 Do linear motion. The magnetic drive module 2 includes a coil former 21 on which an excitation coil 211 is wound and an E-shaped stationary magnetizer assembly 22, and the stationary magnetizer assembly 22 includes a common contact passing through the cavity of the coil former. part 221 and the first and second contact parts 222 and 223 arranged in parallel with the common contact part 221 on the outside of the coil tube 21, the stationary magnetizer assembly 22 consists of two U The magnetic conductor 220 constitutes or integrally forms the structure 22'.

[0031] The bridge moving module 3 includes a movable magnetizer assembly 31 and a contact bridge assembly 32. The movable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com