Resonator, filter and fabrication of resonator

A resonator and filter technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. Adequate adjustment of the resonator resonant frequency filter center frequency, increased production costs, increased manufacturing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

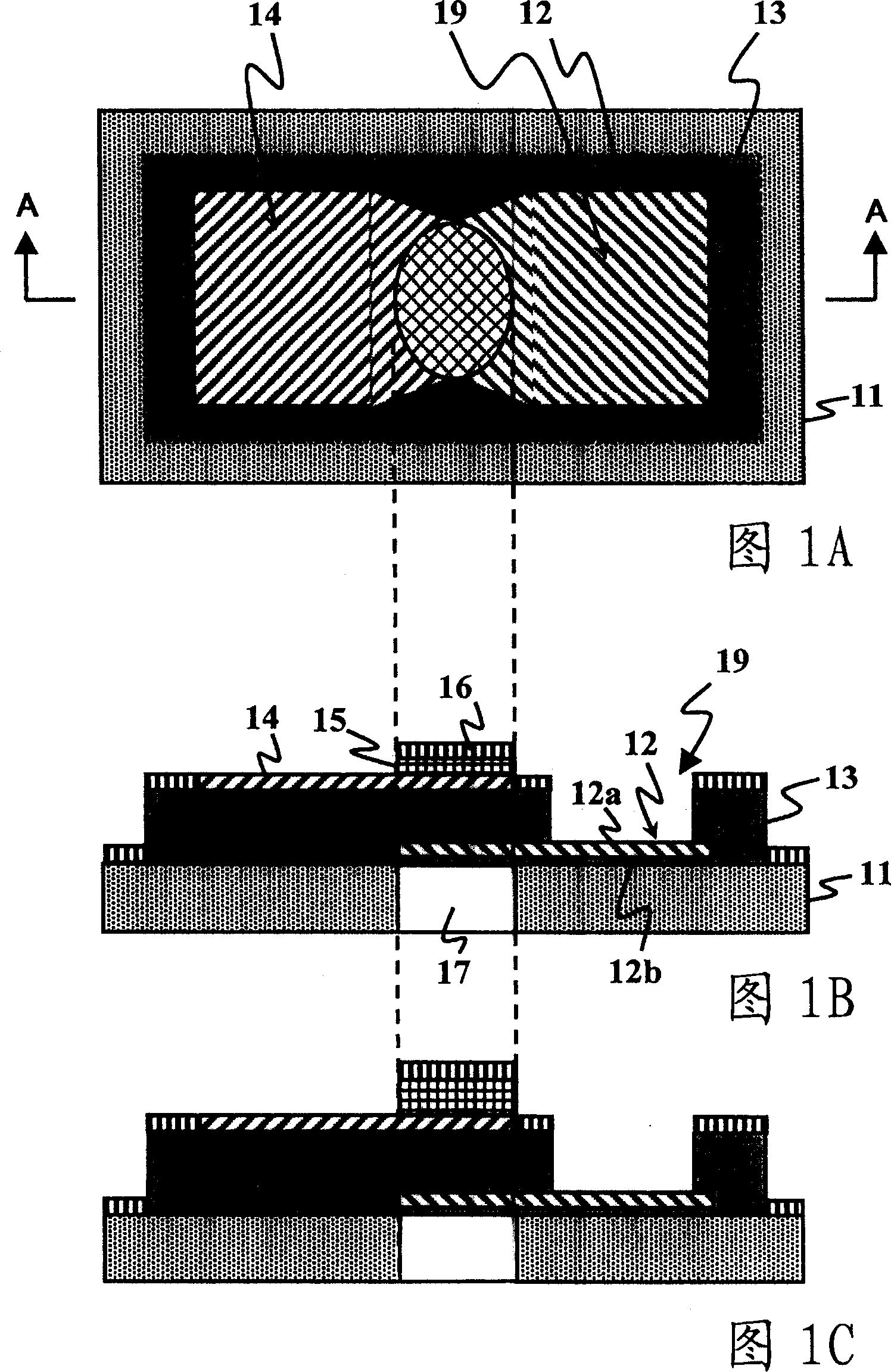

[0041] 1A to 1C show a piezoelectric thin film resonator according to a first embodiment of the present invention. Fig. 1A is a plan view. 1B and 1C are cross-sectional views taken along line A-A shown in FIG. 1A. The piezoelectric thin film resonator shown in FIGS. 1A to 1C can be used as a series branch resonator or a parallel branch resonator of a filter having a ladder structure.

[0042] The piezoelectric thin film resonator includes: a substrate 11 made of a silicon substrate, a lower electrode film 12 , a piezoelectric film 13 made of ALN, and an upper electrode film 14 made of Ru. The lower electrode film 12 has a two-layer structure (Ru / Cr) in which a Ru film 12a and a Cr film 12b are laminated. The first adjustment film 15 is provided on the upper electrode film 14 . Set on the first adjustment film 15 made of SiO 2 The second adjustment film 16 is produced. Made of SiO 2 The produced second adjustment film 16 is also provided on the portion of the substrate 11...

no. 3 example

[0073] 14A to 14C show a piezoelectric thin film resonator according to a third embodiment of the present invention. 14A is a plan view of the resonator, and FIGS. 14B and 14C are cross-sectional views along line A-A shown in FIG. 14A. The piezoelectric thin film resonator in this embodiment can be used as a series branch resonator or a parallel branch resonator.

[0074] The piezoelectric thin film resonator includes a silicon substrate 101, a lower electrode film 102, a piezoelectric film 103 made of AlN, and an upper electrode film 104 made of Ru. The lower electrode film 102 has a two-layer structure (Ru / Cr) in which a Ru film 102a and a Cr film 102b are laminated. In the overlapping region where the upper electrode film 104 and the lower electrode film 102 face each other across the piezoelectric film 103, a layer made of SiO 2 The manufactured first adjustment film 105. Set on the first adjustment film 105 made of SiO 2 The second adjustment film 106 is manufactured....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com