V-belt type variable speed drive

A belt-type continuously variable speed and pulley technology, applied in the directions of portable lifting devices, hoisting devices, transmission devices, etc., can solve the problems of offset, maximum speed reduction, and larger winding diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings.

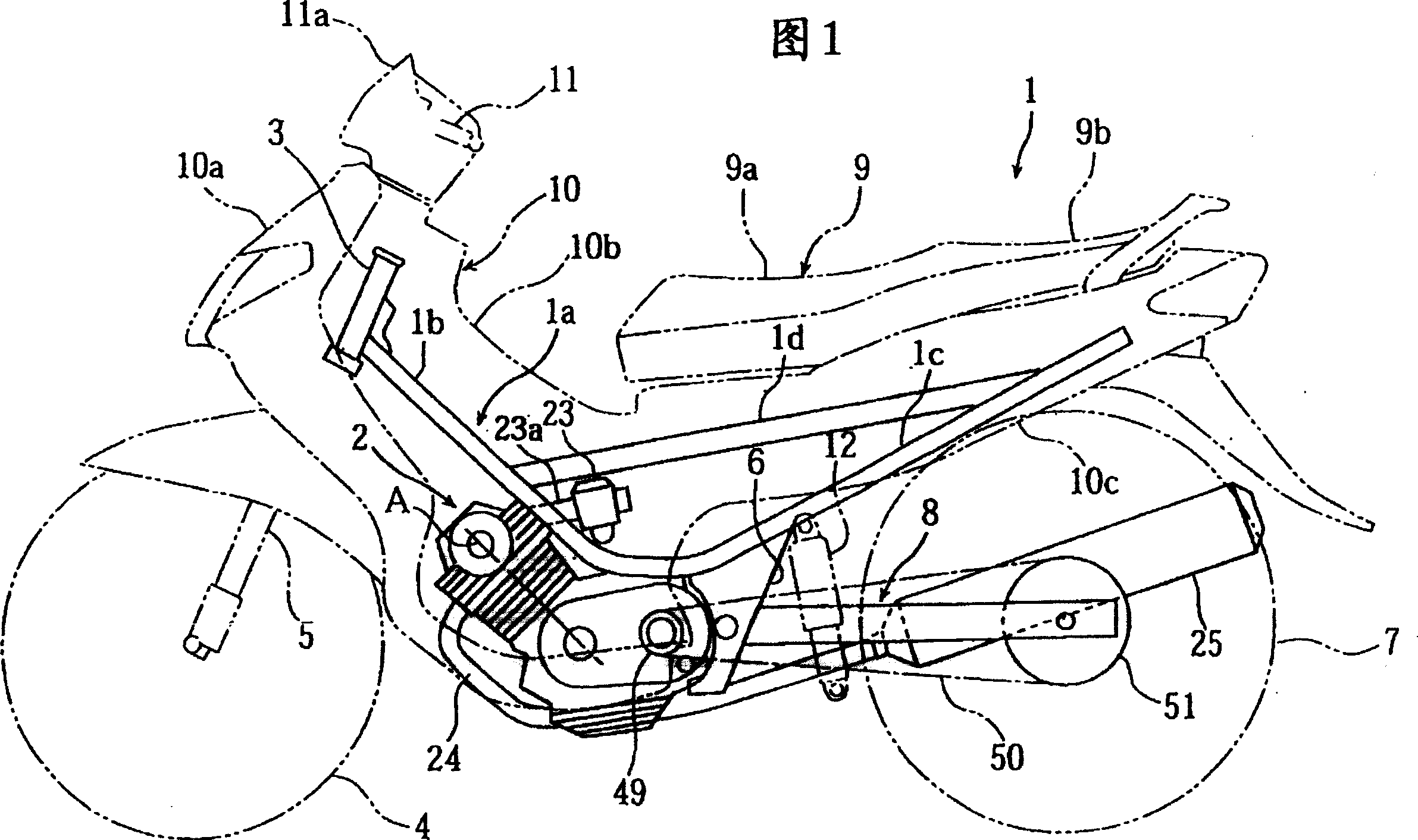

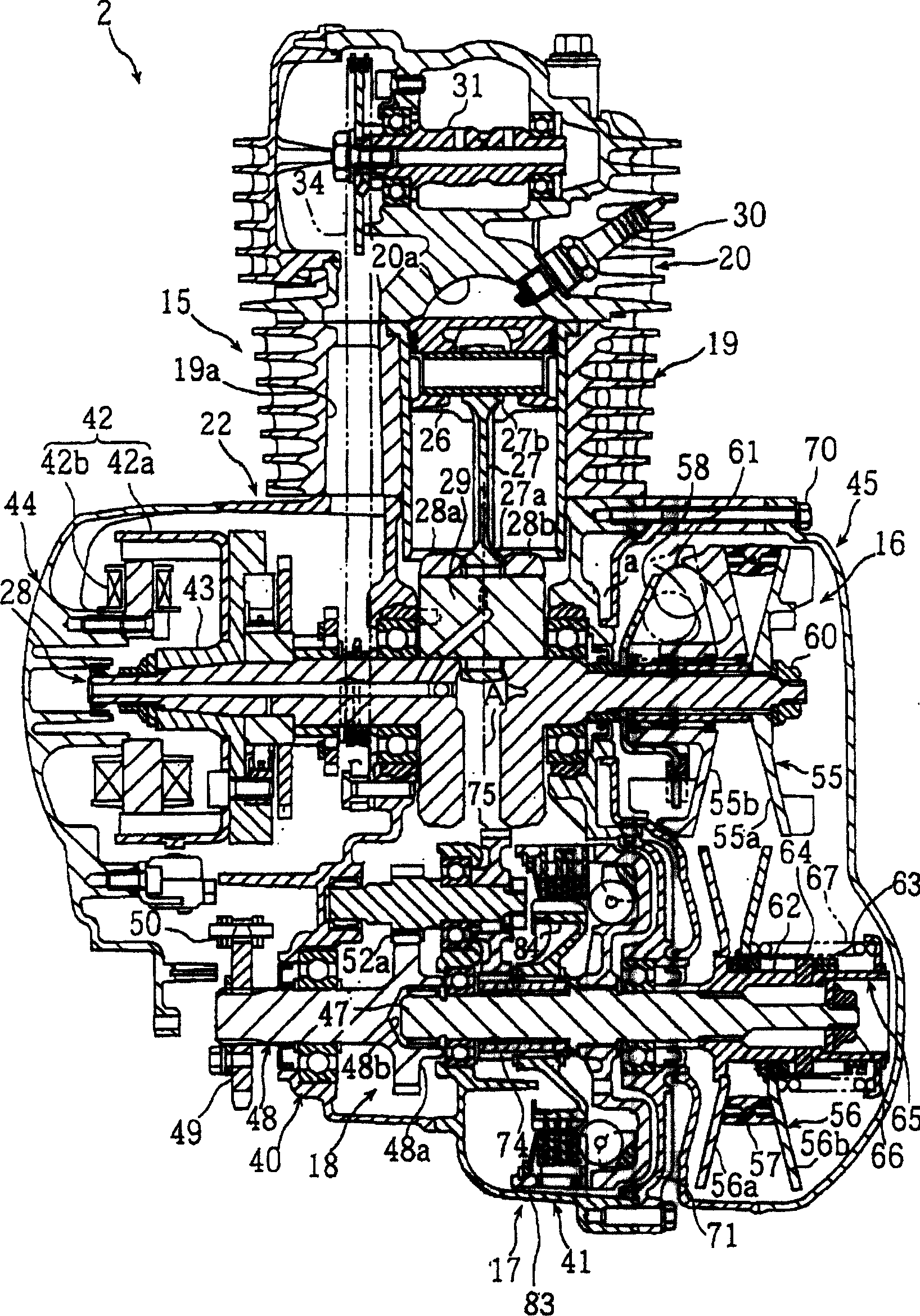

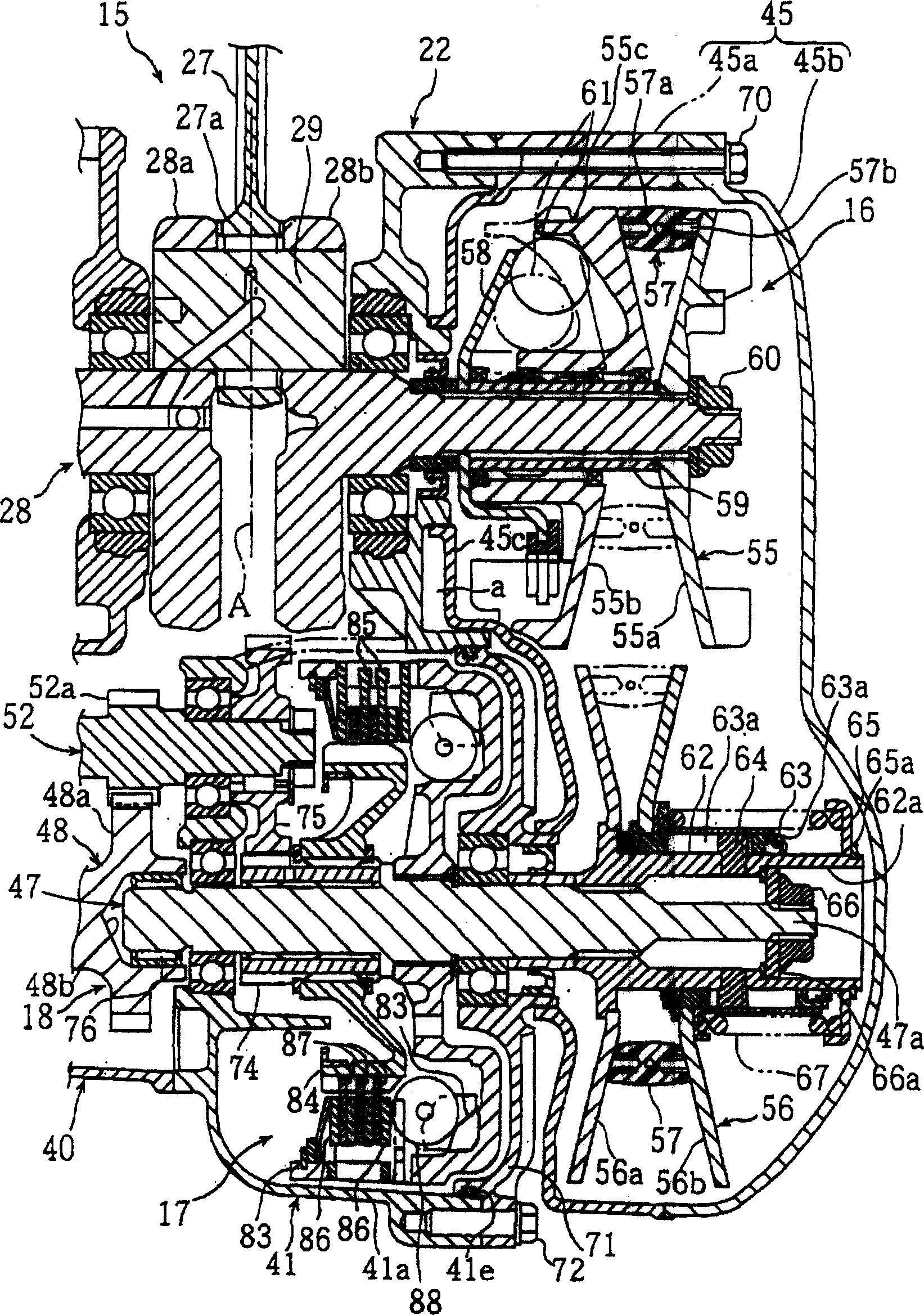

[0030] Figure 1 to Figure 6 It is a figure for demonstrating the V-belt type continuously variable transmission device which concerns on one Embodiment of this invention. FIG. 1 is a left side view of a motorcycle equipped with a V-belt type continuously variable transmission according to the present embodiment, figure 2 It is a sectional plan view of an engine unit equipped with a V-belt type continuously variable transmission, image 3 It is a cross-sectional plan view of a V-belt continuously variable transmission, Figure 4 , Figure 5 , Figure 6 are cross-sectional views showing changes in the winding diameter due to wear of the V-belt. In addition, front and rear and left and right referred to in this embodiment mean front and rear, left and right seen in the state of sitting on the seat.

[0031] In FIG. 1, 1 denotes a two-wheeled motor vehicle, which generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com