Electronic ballast with charge pump for active power factor calibration

A ballast and power rectifier technology, applied in the field of pump circuits, can solve problems such as expensive and achieve the effect of high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

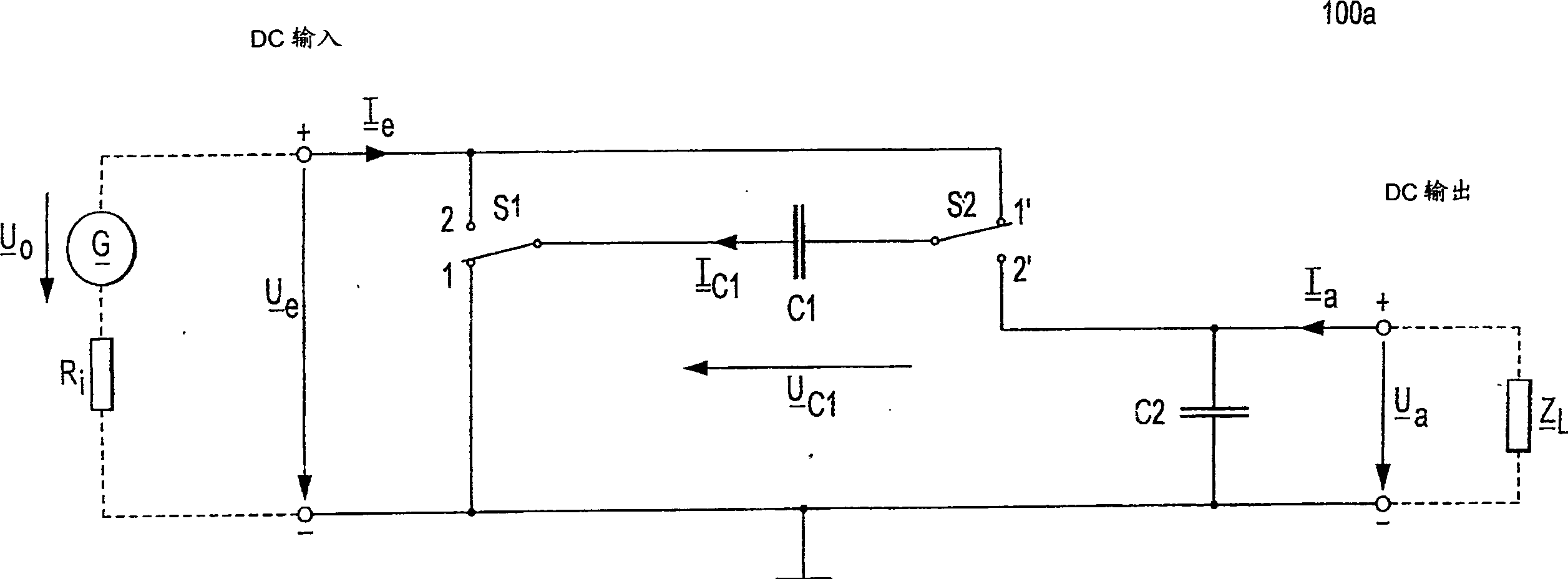

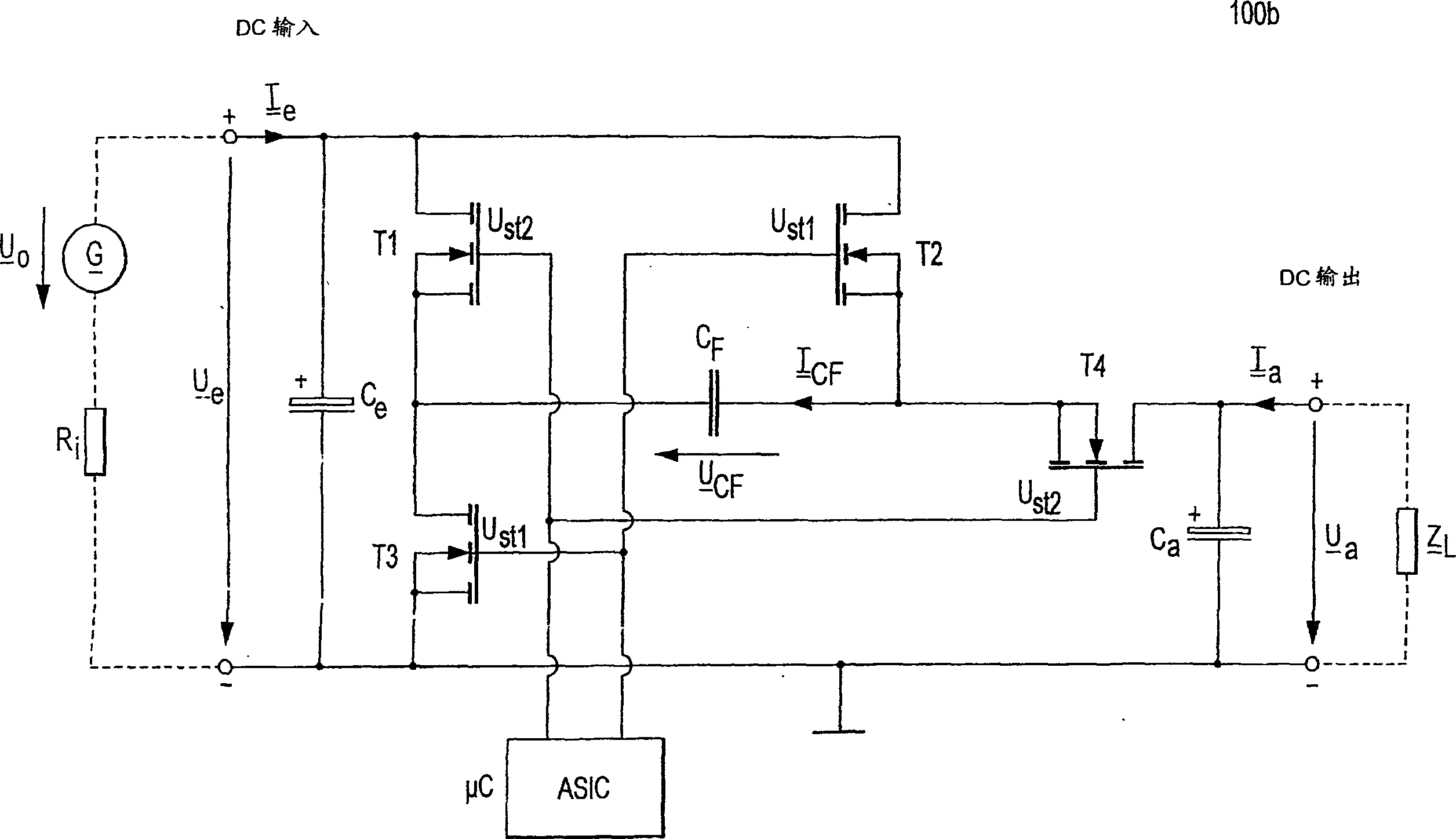

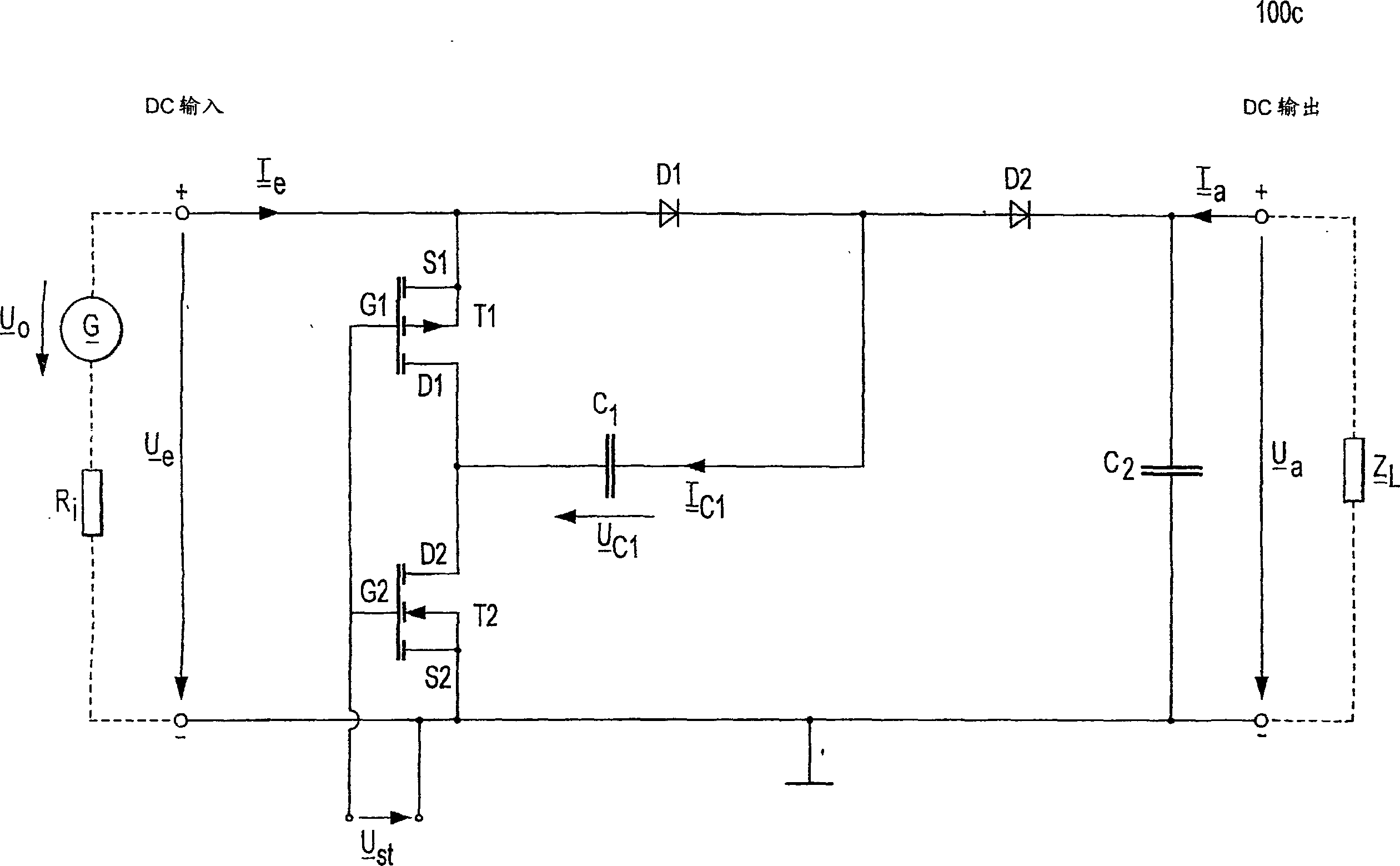

[0053] The following will describe in more detail what is included in the Figure 3a and 3b Functions of the elements in two exemplary embodiments of an active PFC circuit for an electronic ballast (EVG) for low-voltage gas discharge according to the invention shown in .

[0054] Figure 3a A first embodiment of an active PFC circuit 300a according to the invention shown in has a mains rectifier AC / DC implemented as a rectifier full bridge or as a multiplex rectifier for the a.c. voltage U supplied from a current source Netz rectification; storage capacitor C1, connected in parallel with the mains rectifier AC / DC and realized as an electrolytic capacitor (Elko), for obtaining a rectified and smoothed first intermediate circuit voltage U C1 ; with the harmonic filter OWF, connected to this storage capacitor, including along the pulsating d.c. current supplied from the mains rectifier AC / DC I D The two rectifier diodes D1 and D2 set in the forward direction of ; and the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com