Method for controlling burning state of coal powder boiler fire

A technology of combustion state and control method, applied in the direction of combustion method, control combustion, lighting and heating equipment, etc., can solve the problems of slow adjustment process, difficult air distribution operation, and high adjustment frequency, and achieve uniform heating, appropriate distance, increase The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

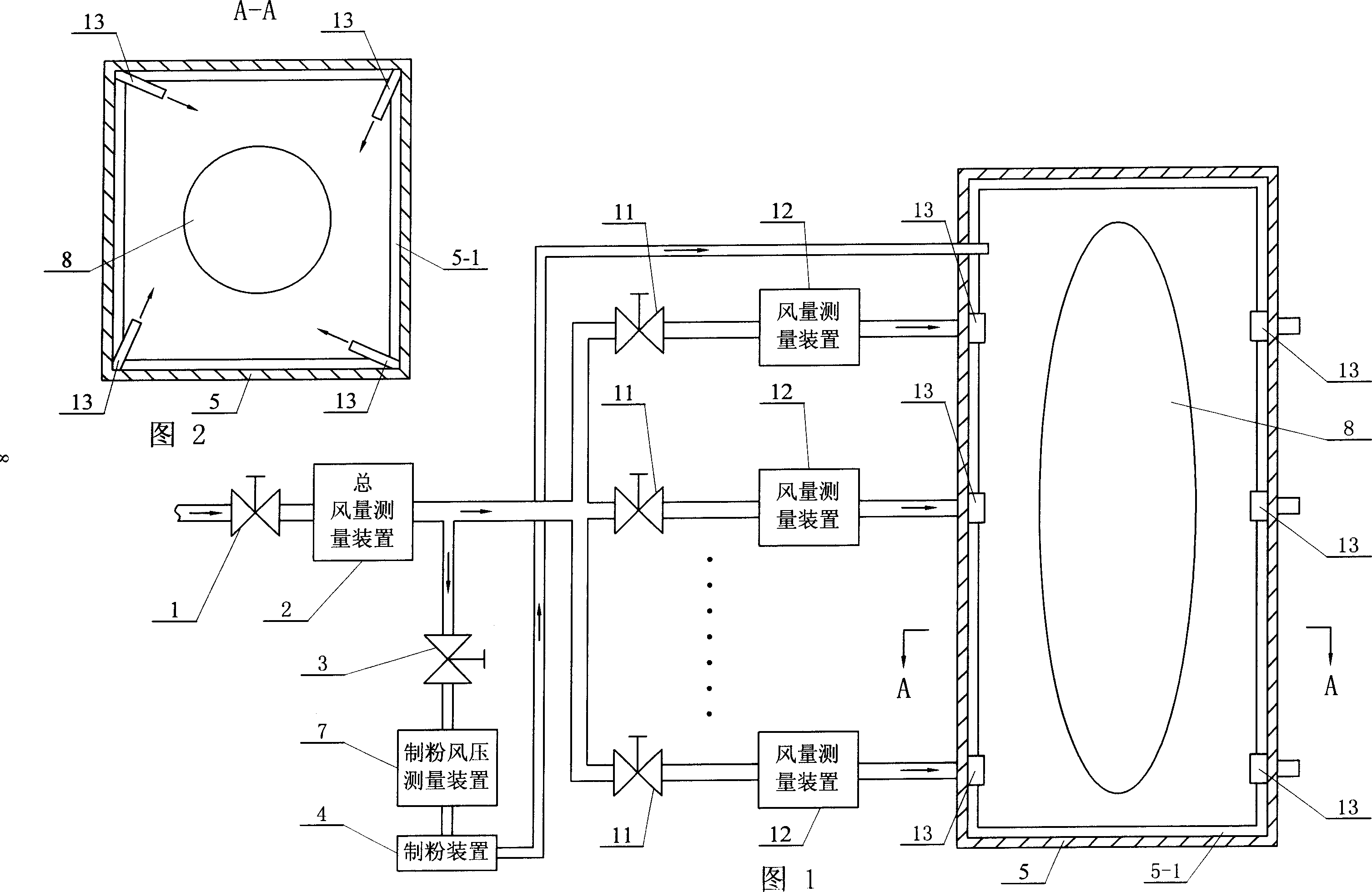

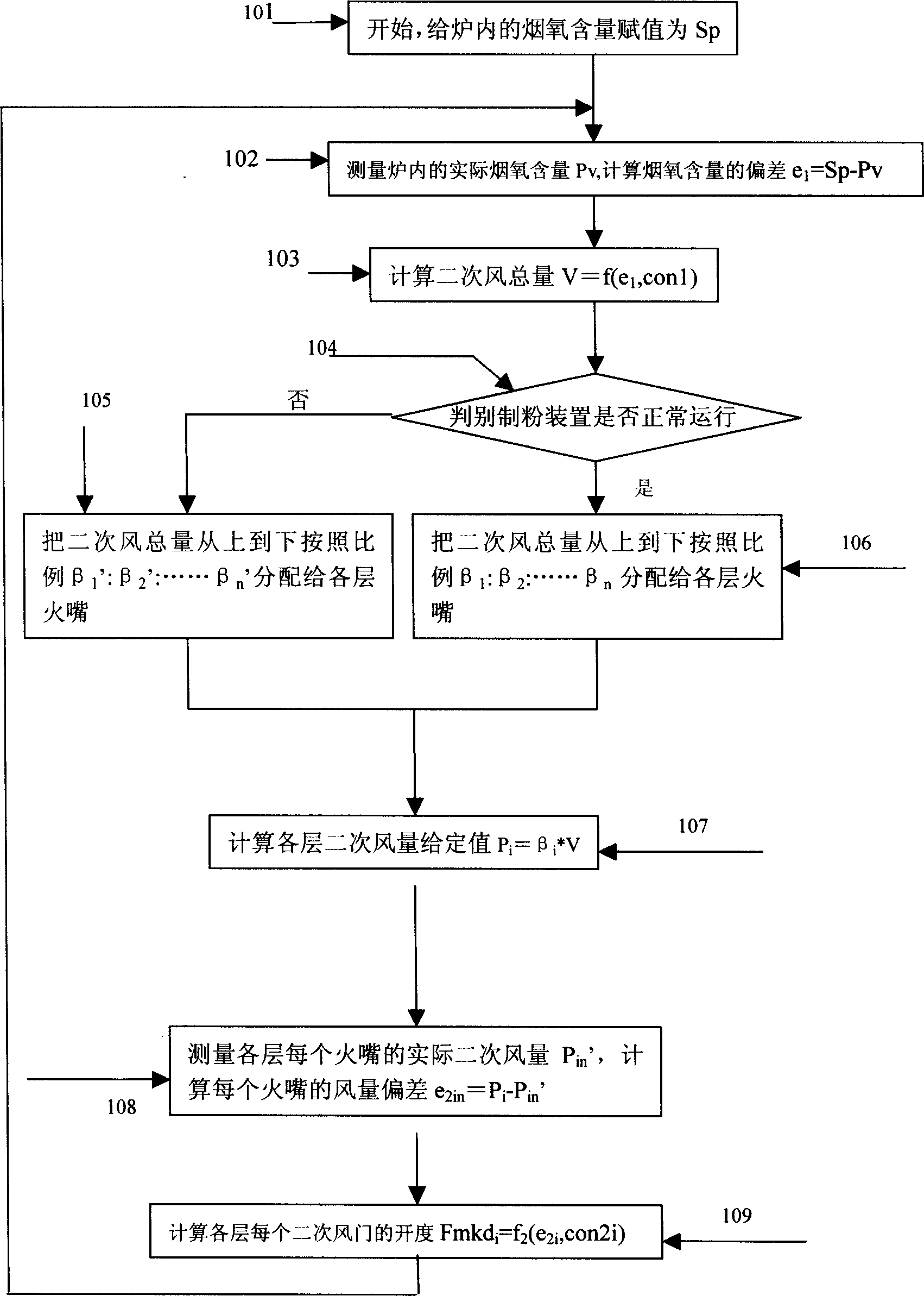

[0006] Specific embodiment one: below in conjunction with Fig. 1 to image 3 This embodiment will be specifically described. The system of this embodiment consists of a total air door 1, a total air volume measuring device 2, a tertiary air door 3, a pulverizing device 4, a pulverizing air pressure measuring device 7, a pulverized coal furnace 5, several secondary air doors 11, and several air volume measuring devices. 12 and a number of nozzles 13, one end of the main damper 1 is connected to one end of the total air volume measuring device 2, and the other end of the total air volume measuring device 2 is connected to one end of the tertiary damper 3 and one end of all secondary dampers 11, and the tertiary damper 3 The other end of the pulverizing wind pressure measuring device 7 is connected to one end of the pulverizing wind pressure measuring device 7, the other end of the pulverizing wind pressure measuring device 7 is connected to one end of the pulverizing device 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com