Method for fabricating sanitary ceramics by using waste sand of quartz

A technology of sanitary ceramics and quartz, which is applied in the field of producing sanitary ceramics by using waste quartz sand, which can solve the problems of high cost of raw materials and achieve the effects of reducing emissions, significant effects, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

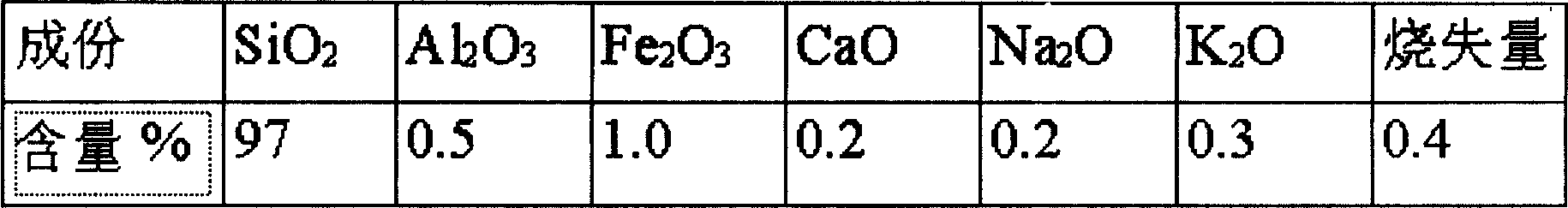

Method used

Image

Examples

Embodiment

[0017] According to the above ratio, the raw material, feldspar, and waste porcelain are crushed to less than 3mm, mixed with quartz waste sand, clay, and purple wood knots, and put into a ball mill for ball milling. The ball milling time is 12-13 hours. After ball milling, grouting Molding, glazing the formed product, the firing temperature of glazing is 1165±15° C., and the firing time is 15 hours to obtain finished sanitary ceramics. In the ball milling process, the ball milling control is: material: ball: water = 1:2:0.45, the loading capacity is 100%; the mud control is: the specific gravity is 1.76-1.78; the mud fineness is 0.8-1.6 per 10,000 sieves; the mud flow The property is 25"-35"; the thickness is 1.8-1.5; the pH value is 7-8.

[0018] Comparison of sanitary ceramics produced by using waste sand and finished sanitary ceramics produced by traditional techniques:

[0019] Product Index

Production of sanitary ceramics from waste sand

traditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com