Assembly parts of high light nut washer

A technology for assembly and fixing nuts, which is applied in the direction of threaded fasteners, locking fasteners, nuts, etc., and can solve problems such as loosening, ineffective anti-theft, and mutual sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with embodiment

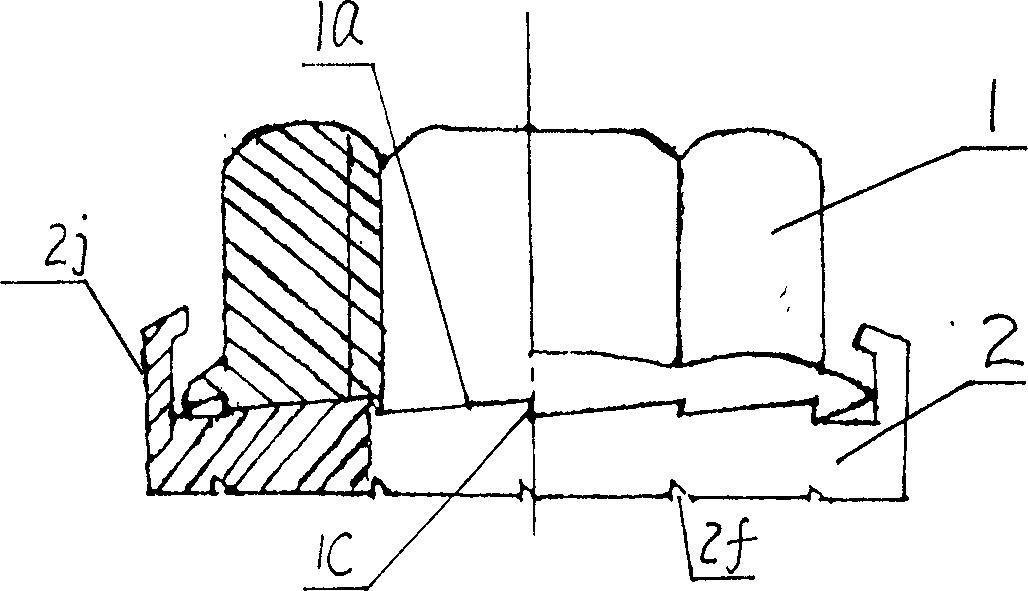

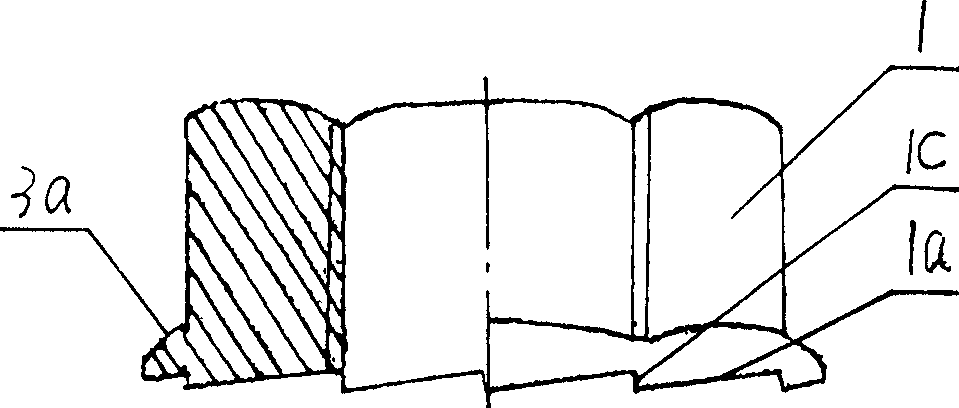

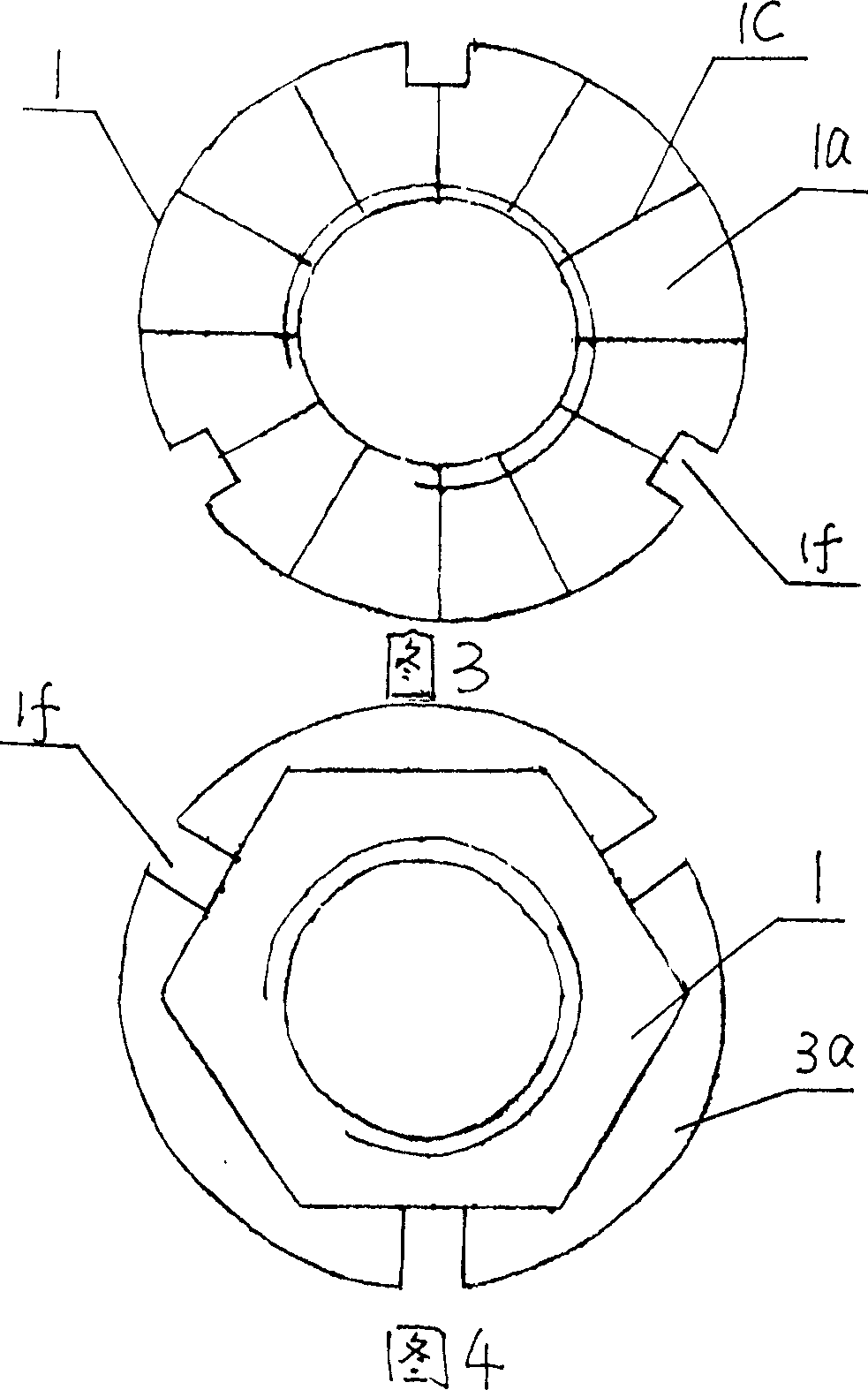

[0016] The structure of a high fastening nut washer assembly of the present invention is as follows: figure 1 , figure 2 , Figure 3, Figure 4, Figure 5 , Figure 6 , as shown in Figure 7: it is composed of a hexagonal flange nut 1 and a gasket 2. Several notches 1f and 3b are respectively arranged on the edges of the nut 1 and the gasket 2. One end of the nut 1 is hexagonal, and the other end is provided with There is a flange surface 3a, and the bottom surface of the flange surface 3a is provided with wedge-shaped inclined surfaces 1a arranged at an equal angle, and one side is high and the other side is low to form an oblique thrust surface. It is the shallowest part of the next wedge-shaped slope 1a, and the junction of each wedge-shaped slope 1a forms a retaining surface 1c with a height difference; the center of the gasket 2 is provided with a perforation 2a, and one side of the gasket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com