Vacuum freeze drying device

A technology of vacuum freeze-drying and drying chamber, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., which can solve the problems of many materials for production, large external dimensions, and high cost, and achieve low production materials and external dimensions. Small, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

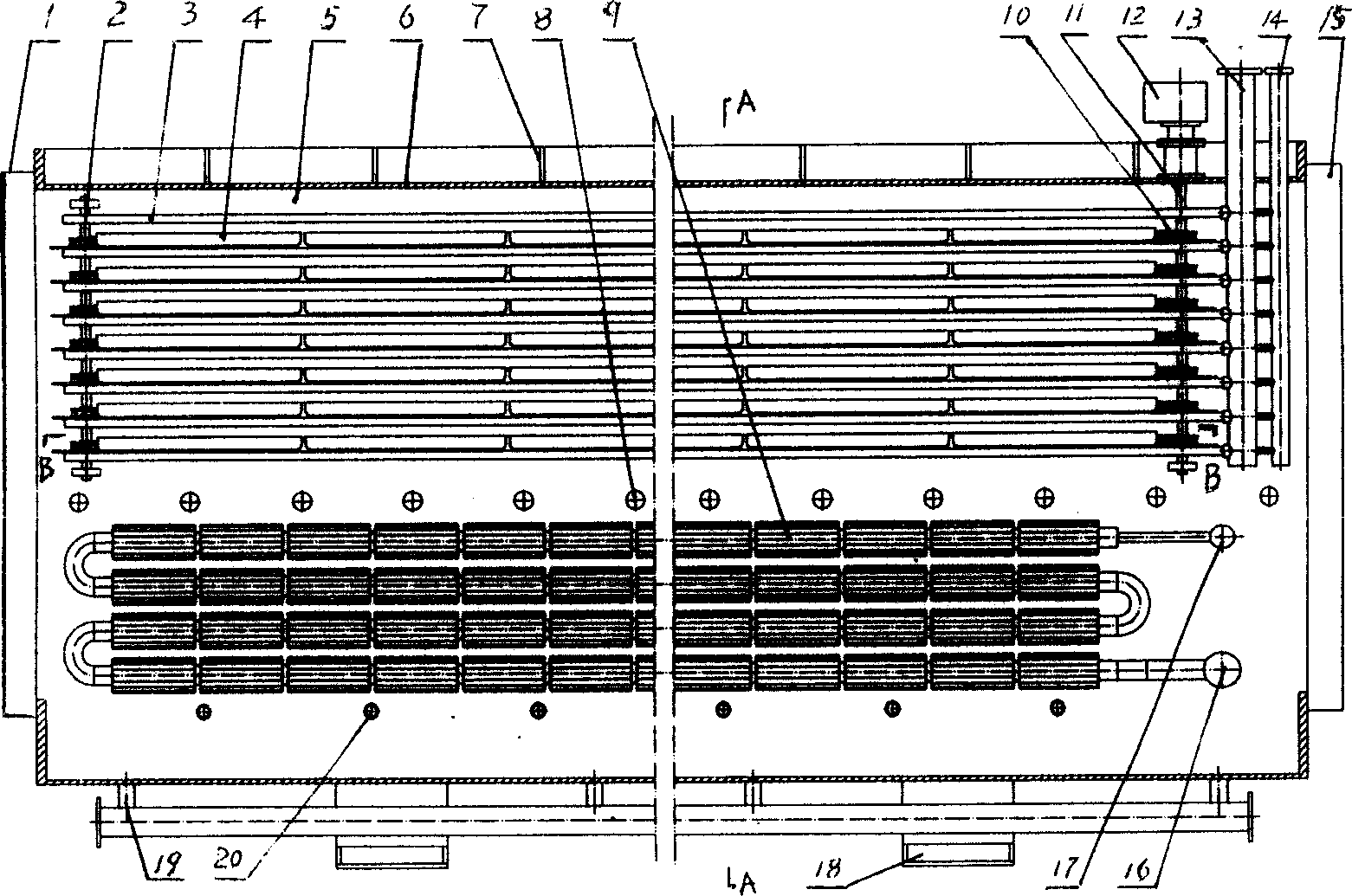

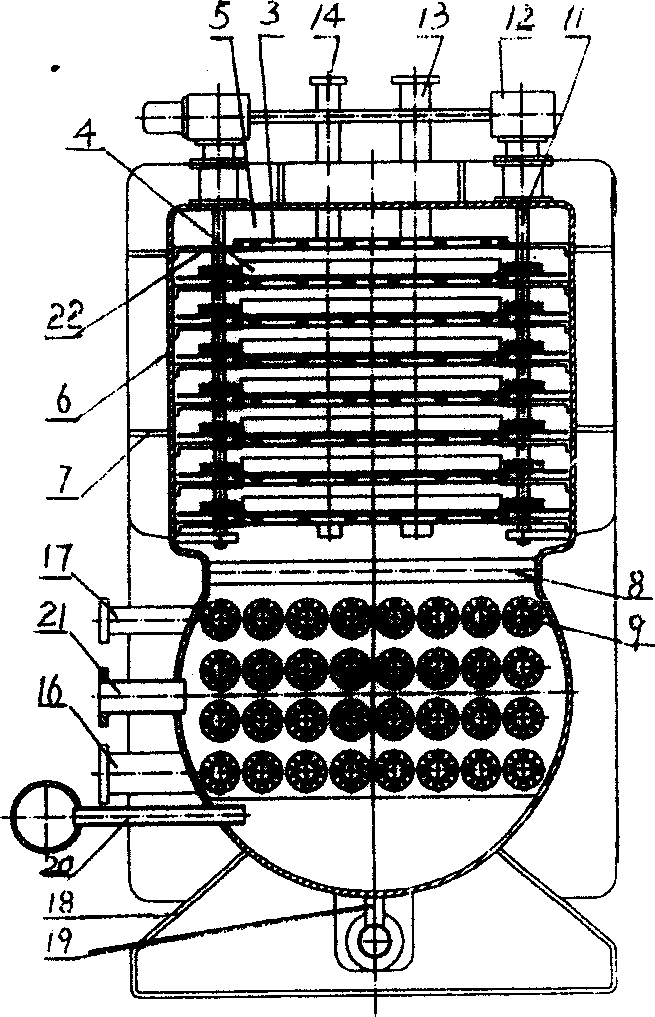

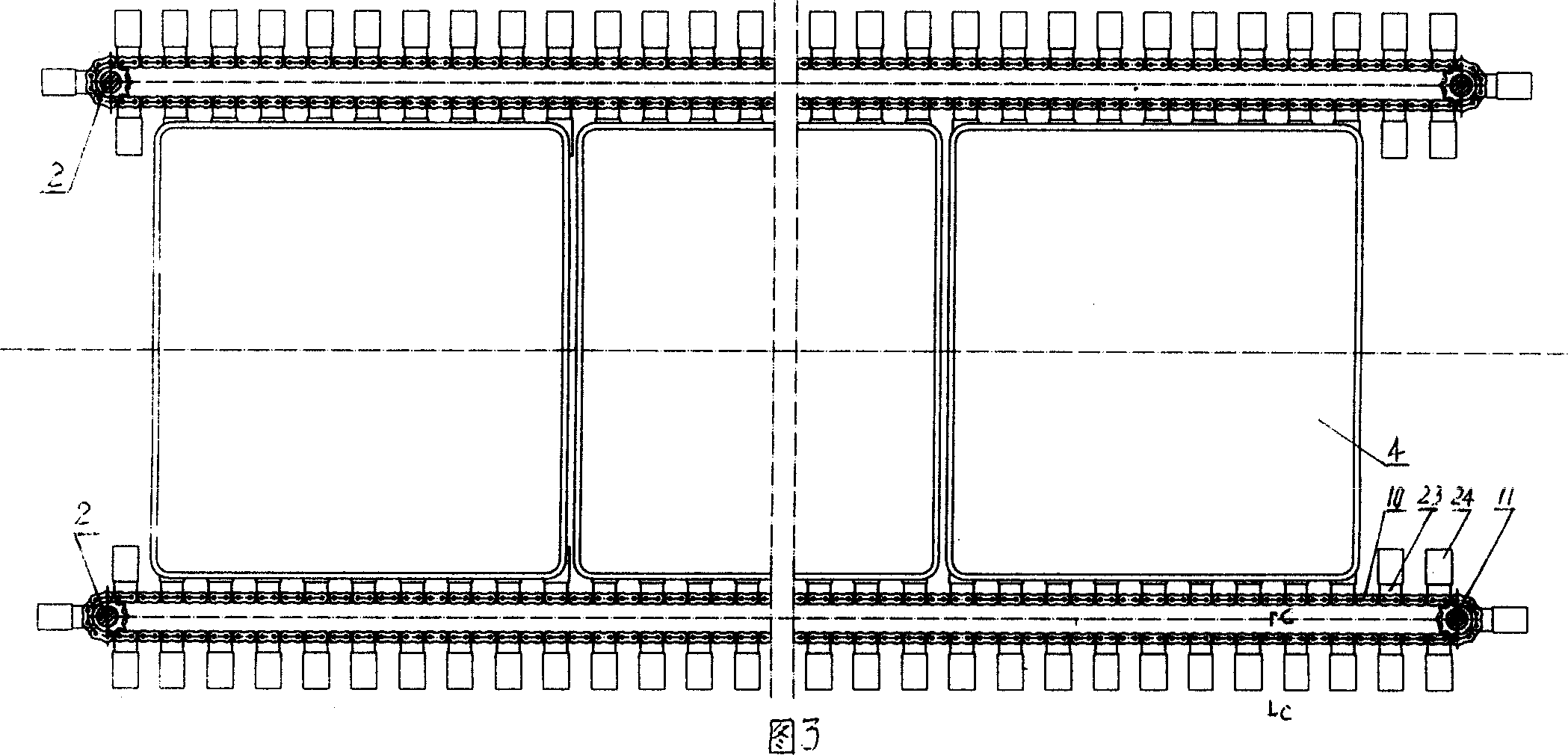

[0013] A kind of vacuum freeze-drying device (see figure 1 , figure 2 ) has a drying chamber 5, supports the heating plate group 3 on the top of the drying chamber with a support 22, communicates with the heating plate group and passes through the heat medium inlet pipe 13 and the heat medium outlet pipe 14 of the drying chamber, and places the trap below the drying chamber. The water evaporator 9, the refrigerant inlet pipe 17 and the refrigerant outlet pipe 16 communicating with the water catcher evaporator and passing through the drying chamber, the vacuum pump connecting pipe 20, the drain pipe 19 and the foot 18 connected with the drying chamber body 6 respectively, the two drying chambers There are airtight doors 1 and 15 at the ends respectively, and the shape of the radial section of the drying chamber is a square or a connection combination of a rectangle and an arc (see figure 2 ), there are load-bearing rods 8 for pressure resistance between the inner sides of th...

Embodiment 2

[0016] The difference from Embodiment 1 is that the drying tray 4 is placed on the heating plate 3 (see FIG. 6 ), and the conveying chain, drive motor and sprocket are omitted.

Embodiment 3

[0018] The difference with Embodiment 1 or 2 is: the drying chamber is provided with a drying disc guide rail 25, and the drying disc is placed on the drying disc guide rail 25 (see Figure 5), and the conveying chain, driving motor and sprocket wheel are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com