Engineering plastic guard bars for highway

A technology of engineering plastics and highways, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of easy oxidation, blackening, and peeling of the galvanized layer, so as to avoid painting maintenance, long service life, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

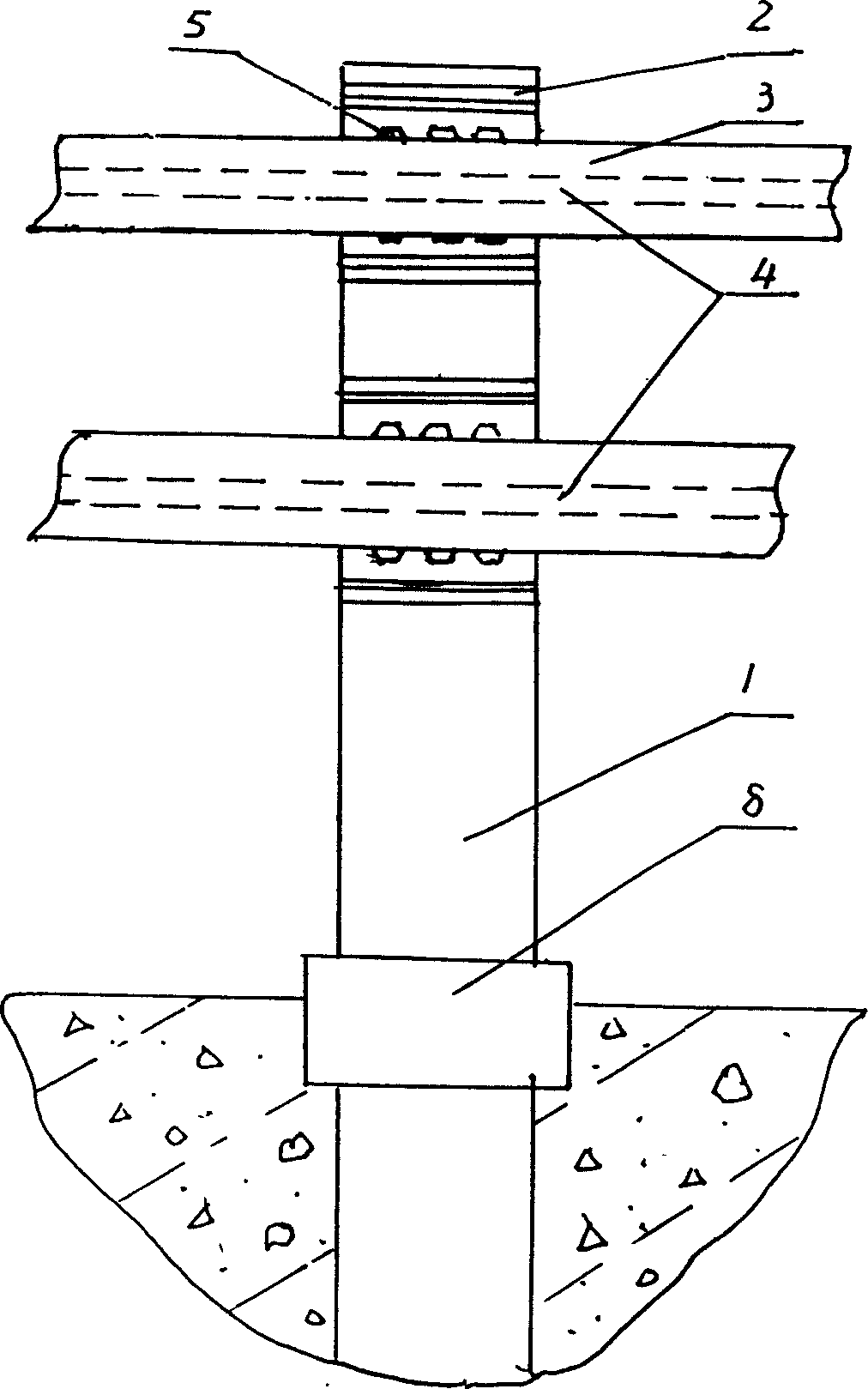

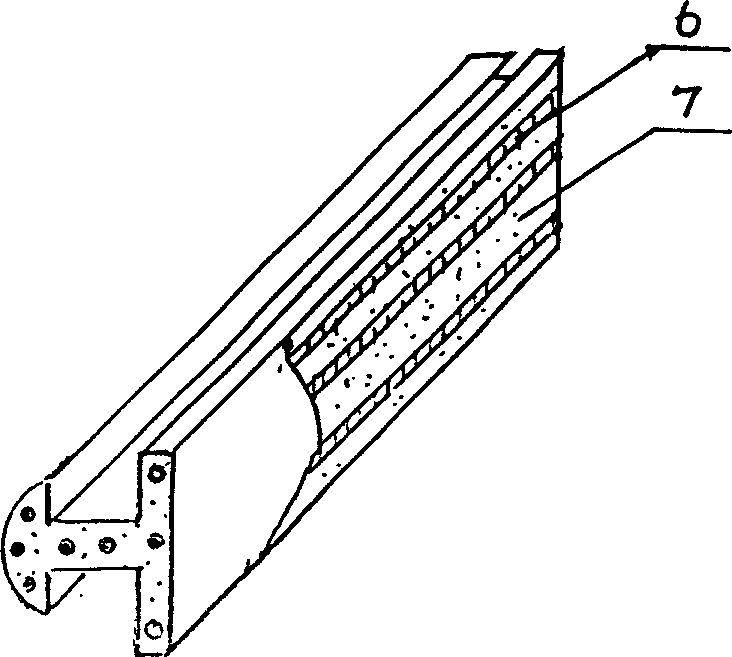

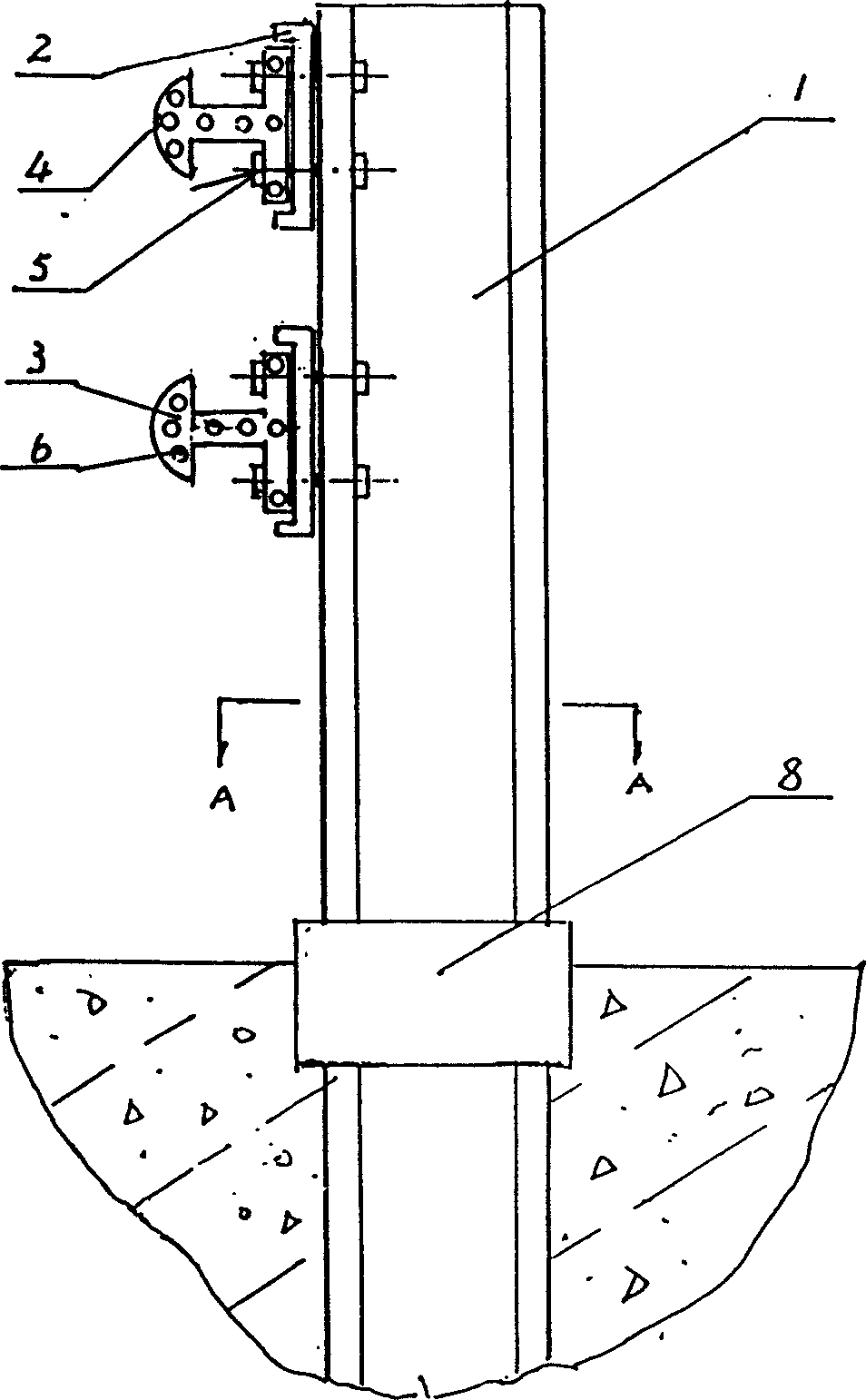

[0011] choose light Steel or Shaped plastic steel is used as a column (1), and a bolt hole for installing a guard plate (3) is established on the top of one wing; After modified by additives such as colored mineral pigments, it is extruded into a cross-section of Glyph sheet, when extruded, in A continuous luminous powder line (4) is injected into the middle of the top of the glyph, and after cooling and setting, the steel bar and plastic are solidified together; the elastic gasket (2) is an elastic rubber gasket; the guard plate (3) and the elastic gasket (2) Bolt holes are correspondingly established on the top, and the guard plate (3) and elastic gasket (2) are fixed on the top of the column (1) with bolts (5). The elastic sleeve (8) adopts elastic rubber, and the bottom of the column (1) is buried in the soil or concrete after the elastic sleeve (8) is set close to the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com