Extended nip press for the leather industry

A wide nip, press technology used in presses, manufacturing tools, leather flattening/rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

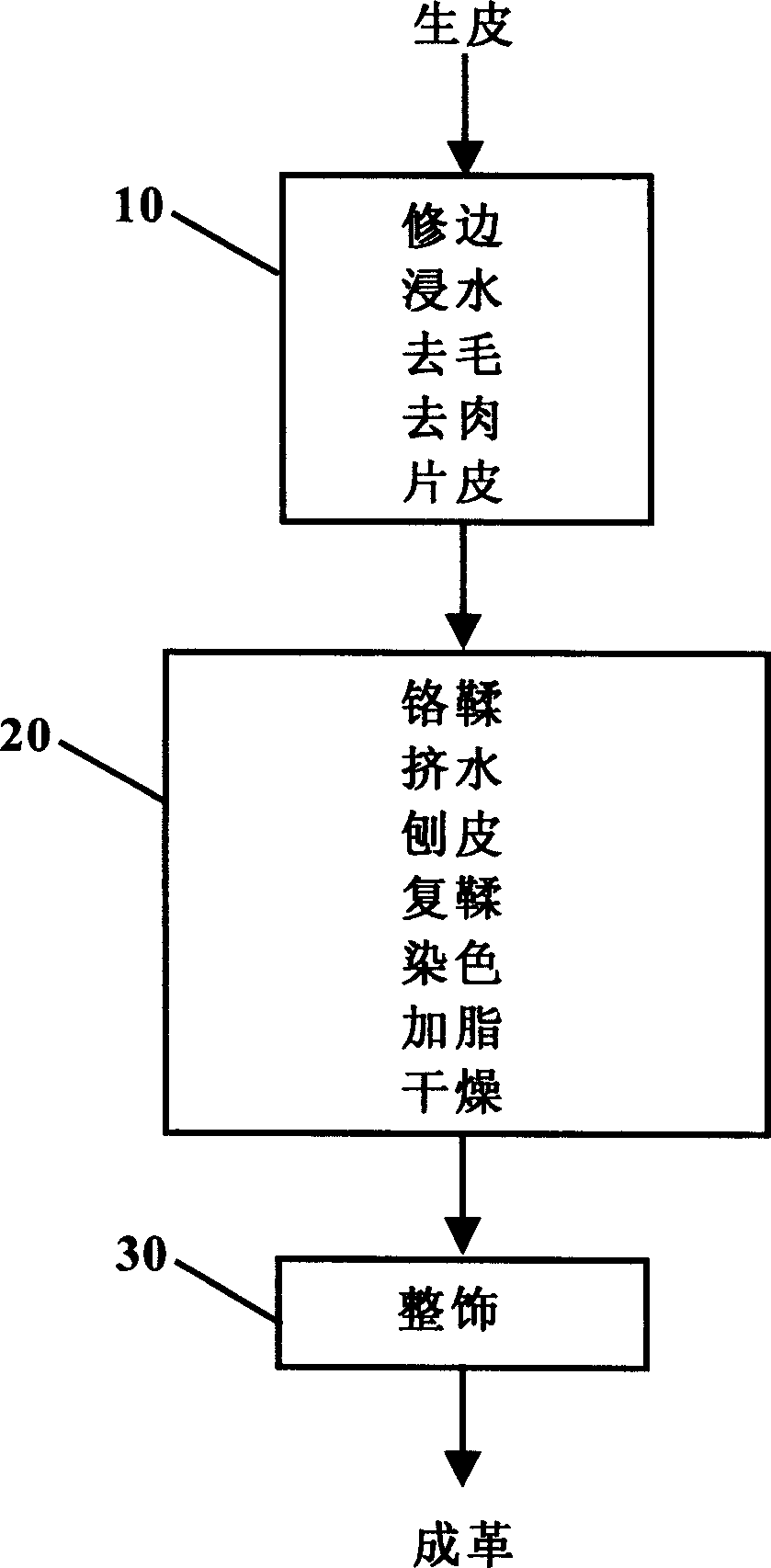

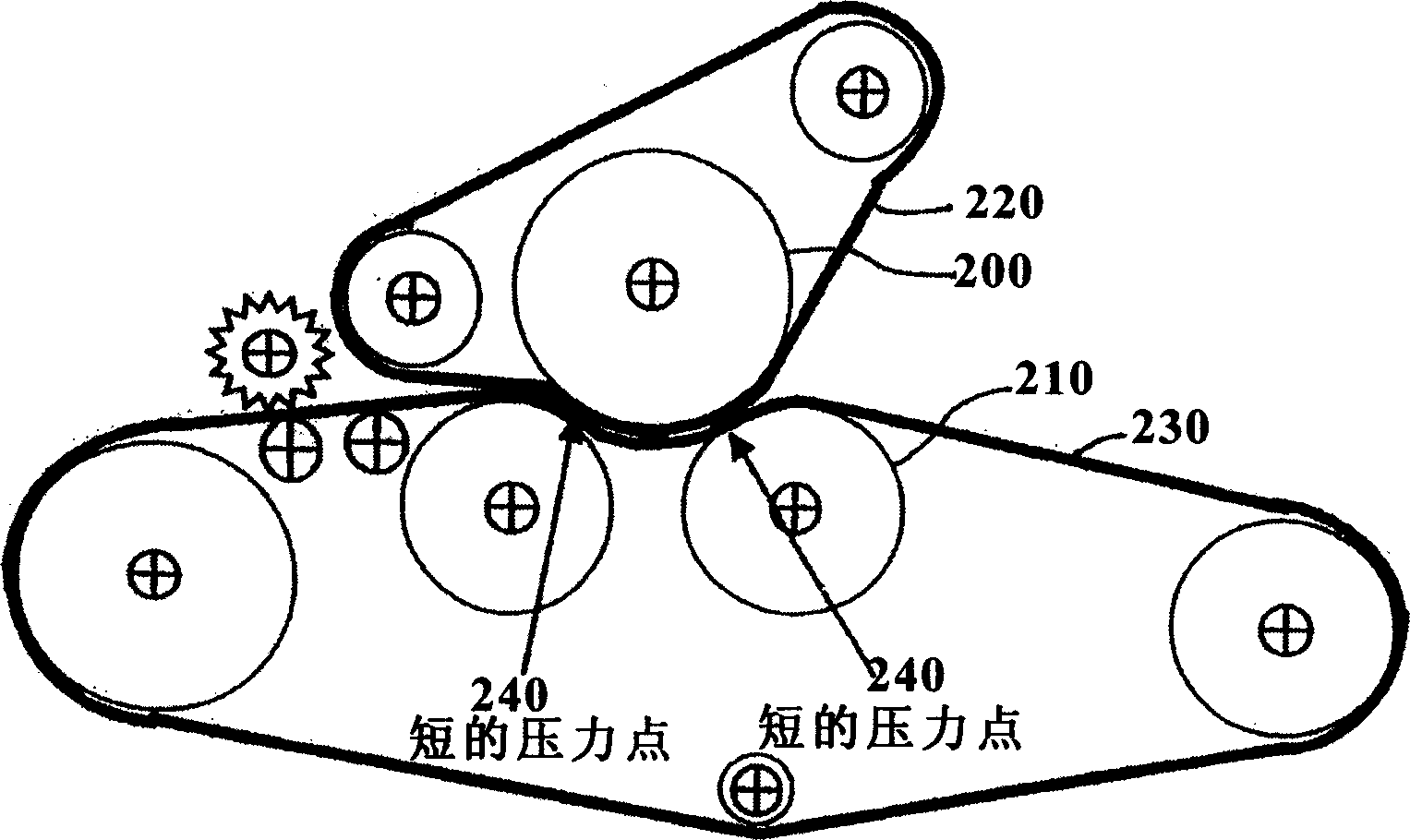

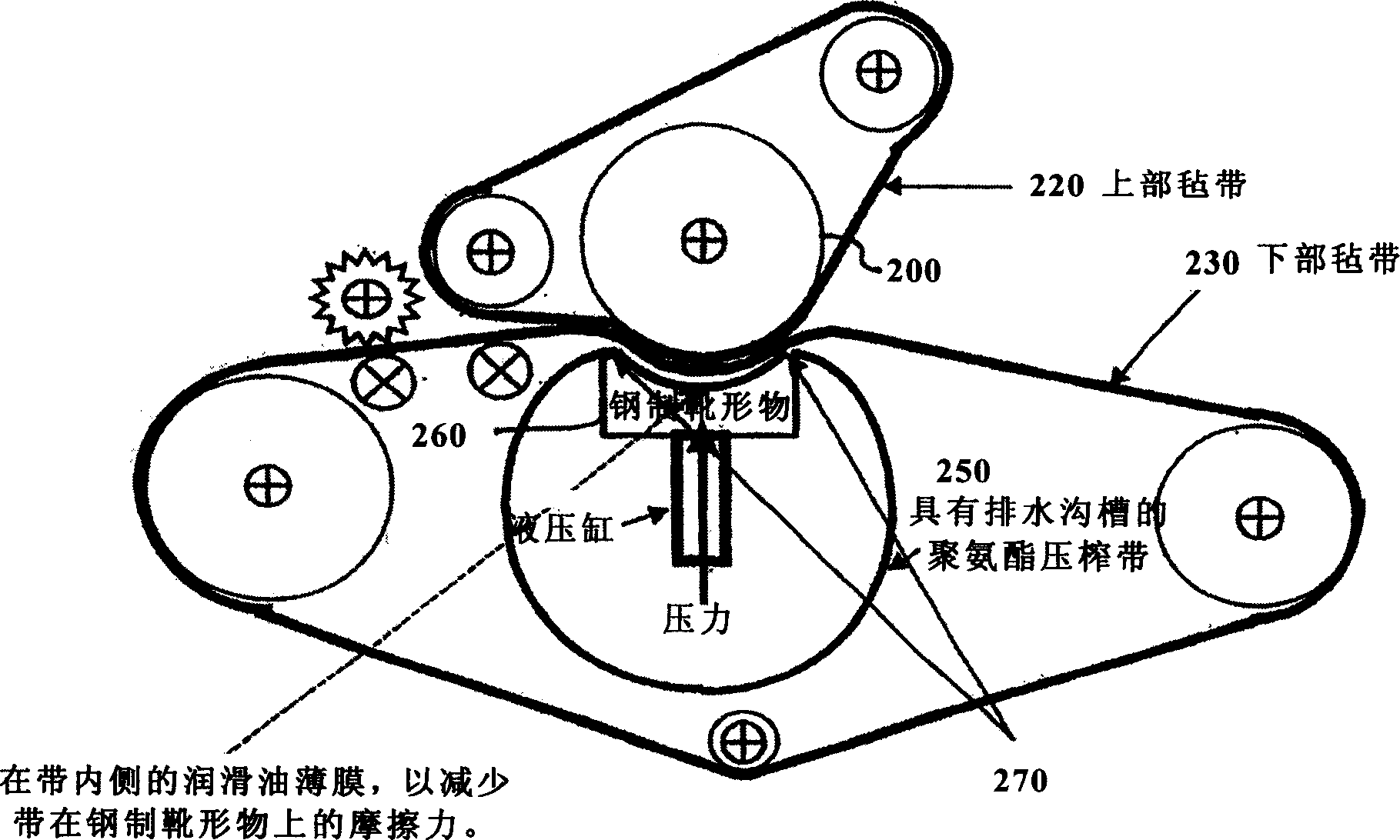

[0025] A preferred embodiment of the present invention is a wide nip press capable of efficiently removing water from hides during the squeezing / wetting operation. In the early 1980s, the concept of a wide-nip press, or shoe press, emerged in the paper industry. The shoe press replaces the traditional concept of opposing twin rolls. In place of one of the rollers, a curved steel shoe is placed to substantially match the radius of the opposite roller. An endless belt coated with elastic compound spans the surface of the boot. A thin film of oil lubricates the shoe / belt interface. This concept is generally referred to as "fluid dynamic bearing". The force exerted on the steel shoe by the hydraulic system creates a pressure between the steel shoe and the roller. The opposing rollers are in fixed positions.

[0026] In the paper industry, paper is formed by depositing a fiber-containing slurry onto a moving forming fabric. Supported by a press fabric, the paper passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com