Manufacturing method of color visible light-focusing line and its device

A production method and visible light technology, applied in optics, optical components, image duplicators, etc., can solve the problems of large volume and power consumption, large volume, large power consumption, unfavorable integration, etc., and achieve simple composition, low power consumption, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

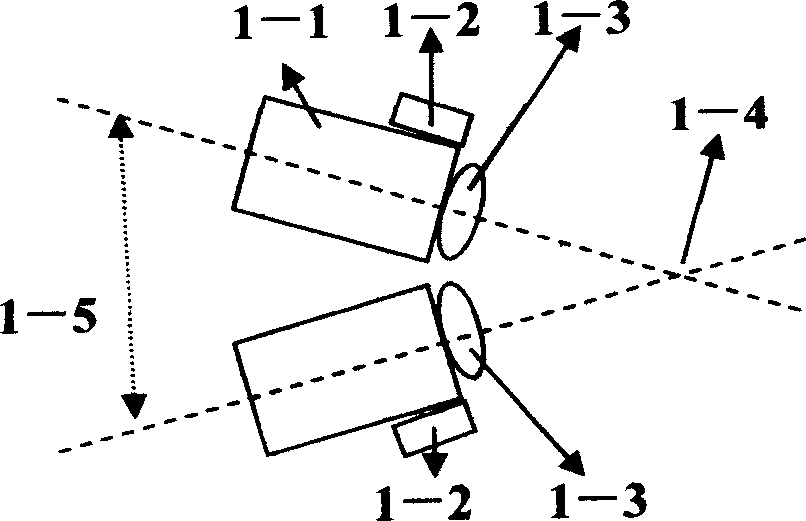

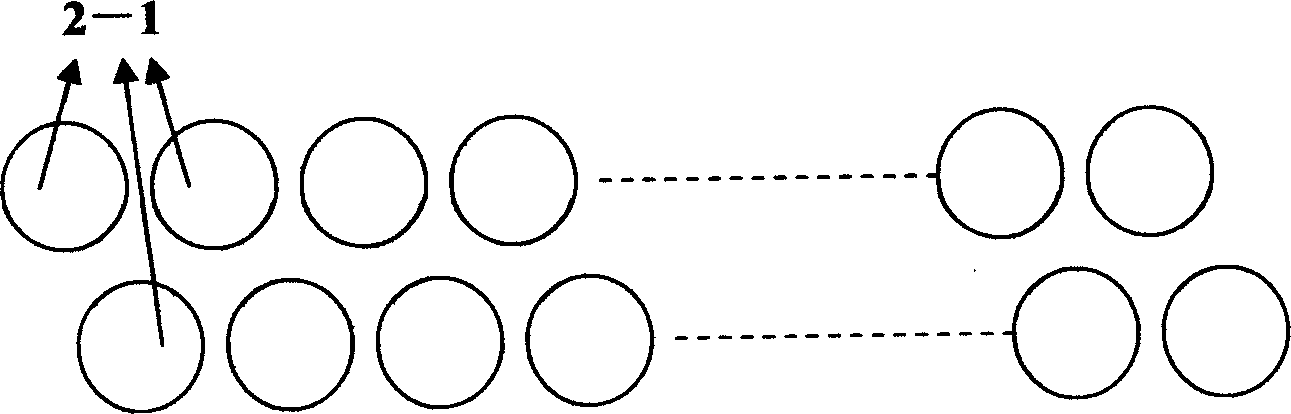

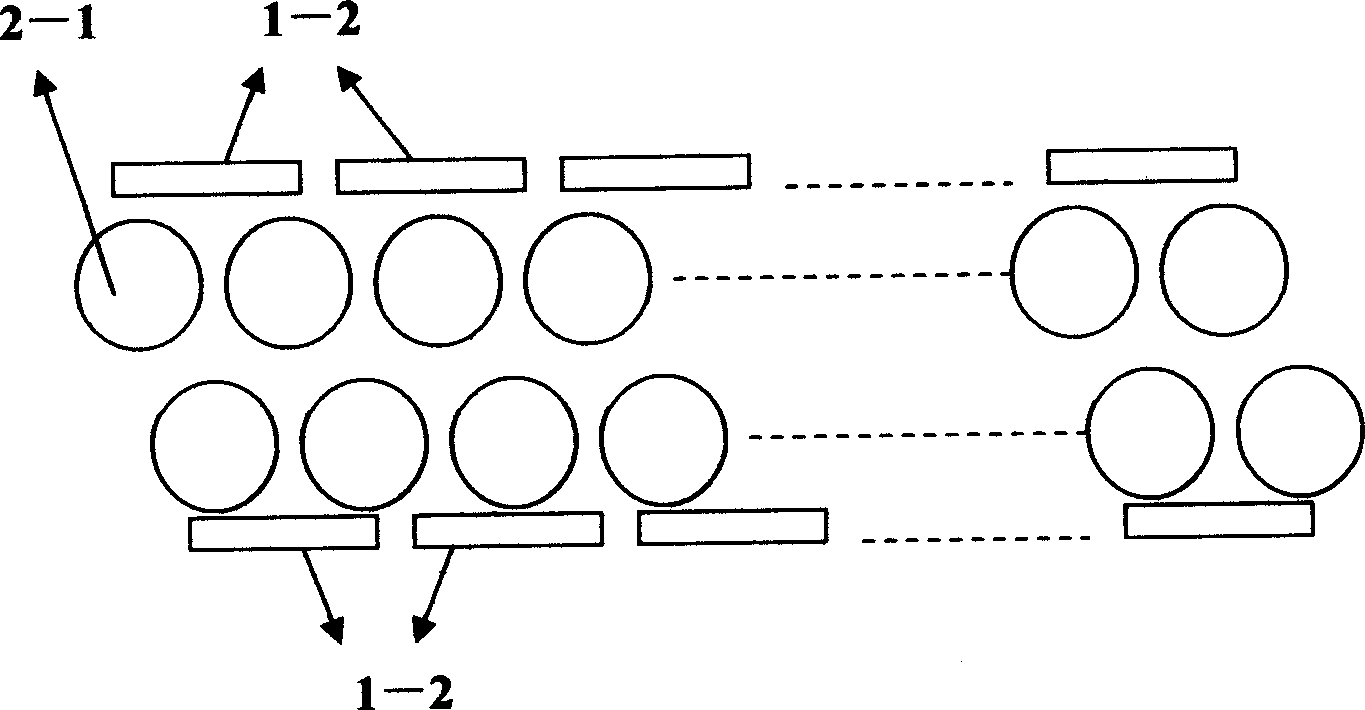

[0026]In the colored visible light condensing row device of the present invention, the three primary color light-emitting units are composed of three primary color high-brightness red, green, and blue semiconductor laser light-emitting tubes or three primary-color high-brightness red, green, and blue light-emitting diodes, and the three primary color light-emitting units are formed into a long strip according to certain rules to form three primary colors Light-emitting tube rows, and each of the three primary color light-emitting units is equipped with a condenser one-to-one, so that when the three primary color light-emitting tube rows emit light at the same time according to different color signals, a row of colored visible light rows is generated. After the colored visible light rows are focused by the condenser row, the focus The dots form a line consisting of colored focused spots to form a color video electrical signal converted into a colored visible light visible video p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com