A groove composite multi-protrusion structure and its preparation process

A preparation process and recessed structure technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of high cost and poor repeatability of the preparation process, and achieve the improvement of light absorption capacity and SERS activity. , the effect of improving Raman performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

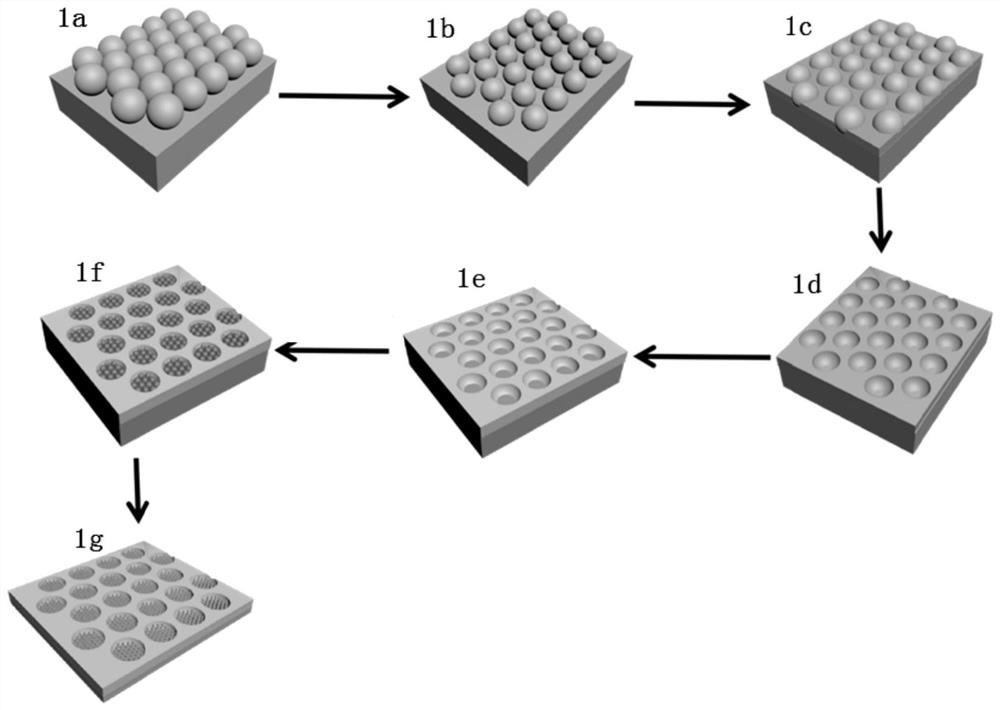

[0044] Example 1 - Fabrication of Groove Composite Multi-Protrusion Structure by Reactive Ion Etching Process

[0045] Step 1. Forming a silicon-based groove array structure

[0046] Step 1a, put the silicon wafer into deionized water, acetone, ethanol, concentrated sulfuric acid, hydrogen peroxide, and deionized water in sequence for ultrasonic cleaning, each liquid is ultrasonically cleaned for 30-40 minutes, and then the cleaned silicon wafer is dried at 120°C For treatment, the drying time is 20 minutes; after the water on the silicon wafer is completely evaporated, the silicon wafer is placed in an ultraviolet ozone cleaning machine for 30 minutes of irradiation to obtain a silicon wafer with a hydrophilic surface. Take 30 microliters of PS colloidal sphere suspension with a content of 2.5wt% and a diameter of 100 nm, mix it with ethanol in an equal volume, and then perform ultrasonic oscillation for 10 to 30 minutes, so as to obtain a uniformly dispersed ethanol dilution...

Embodiment 2

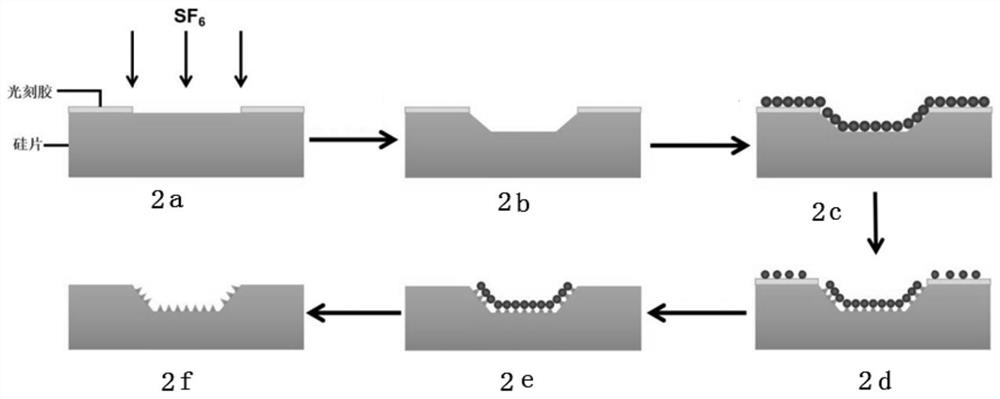

[0053] Example 2 - Preparation of groove composite multi-protrusion structure by photolithography technology combined with reactive ion etching process

[0054] The specific operation process of the photolithography process is in the prior art, and will not be repeated here. Due to the limitation of the lithography precision of the lithography instrument, the interval period width of the lithography mask plate during lithography is 10um. After constructing grooves with a width of 10 μm through the existing photolithography technology and reactive ion etching process, a 100 nm PS ball array was prepared by the same method as in step 1a of Example 1, and the above-mentioned obtained width of The 10um silicon-based groove array structure is compounded. After the above-mentioned silicon plate is naturally air-dried, the 100nm PS ball array is used as a secondary mask layer, and then the same process parameters as in the second etching of Example 1 are used for reactive ion etching...

Embodiment 3

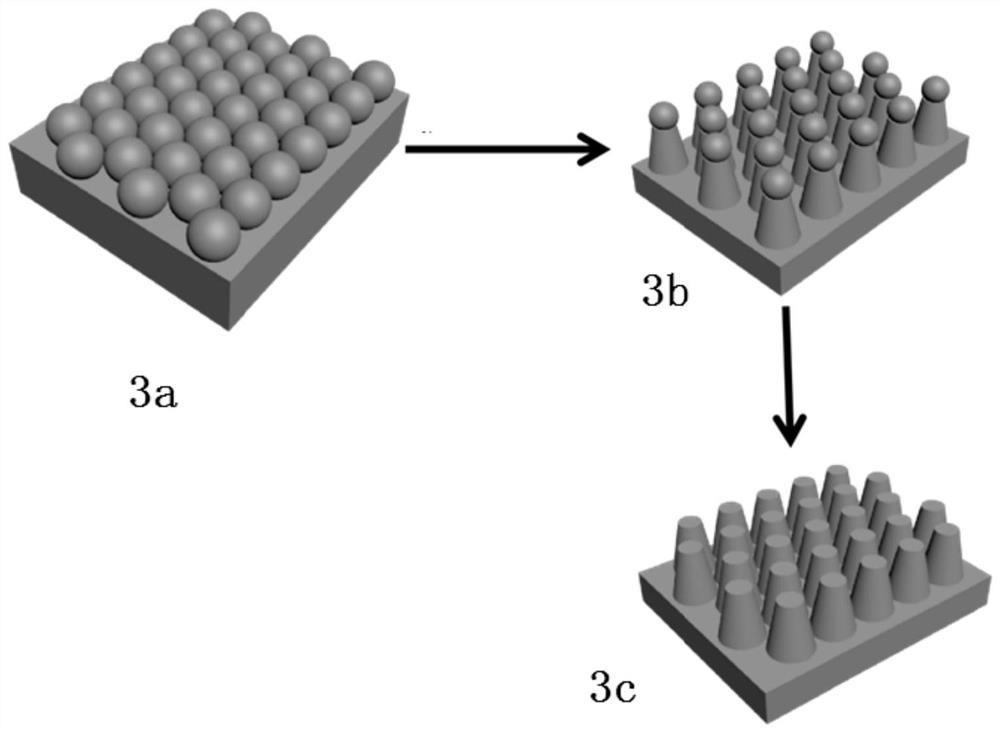

[0055] Example 3 - Fabrication of Groove Composite Multi-Protrusion Structure by Reactive Ion Etching Process

[0056] Step 1. Forming a silicon-based groove array structure

[0057] Step 1a, using the same method as step 1a in Example 1, respectively obtain a 100nm single-layer ordered hexagonal close-packed PS sphere array and a 500nm single-layer ordered hexagonal close-packed PS sphere array, such as Figure 6 Shown in a.

[0058] Step 1b, performing plasma etching on the 500nm single-layer ordered hexagonal close-packed PS sphere array prepared in step 1a, using oxygen as the working gas, controlling the gas flow at 30 sccm, maintaining the gas pressure at 3Pa, and controlling the etching power at 200W, and the total etching time is 40s at high-end or 3min at mid-range, so as to obtain a non-hexagonal close-packed PS ball array structure with a surface size of 350nm-450nm on the silicon wafer, such as Figure 6 Shown in b.

[0059] Step 1c, using the non-hexagonal clos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com