Method and equipment for measuring torsional vibration of rotating mechanical rotor

A technology of torsional vibration and rotating machinery, which is applied in the directions of measuring devices, rotation vibration suppression, vibration testing, etc. It can solve problems such as poor working conditions, difficult to realize, difficult torsional vibration signal extraction and analysis, etc., and achieves simple installation and high reliability , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

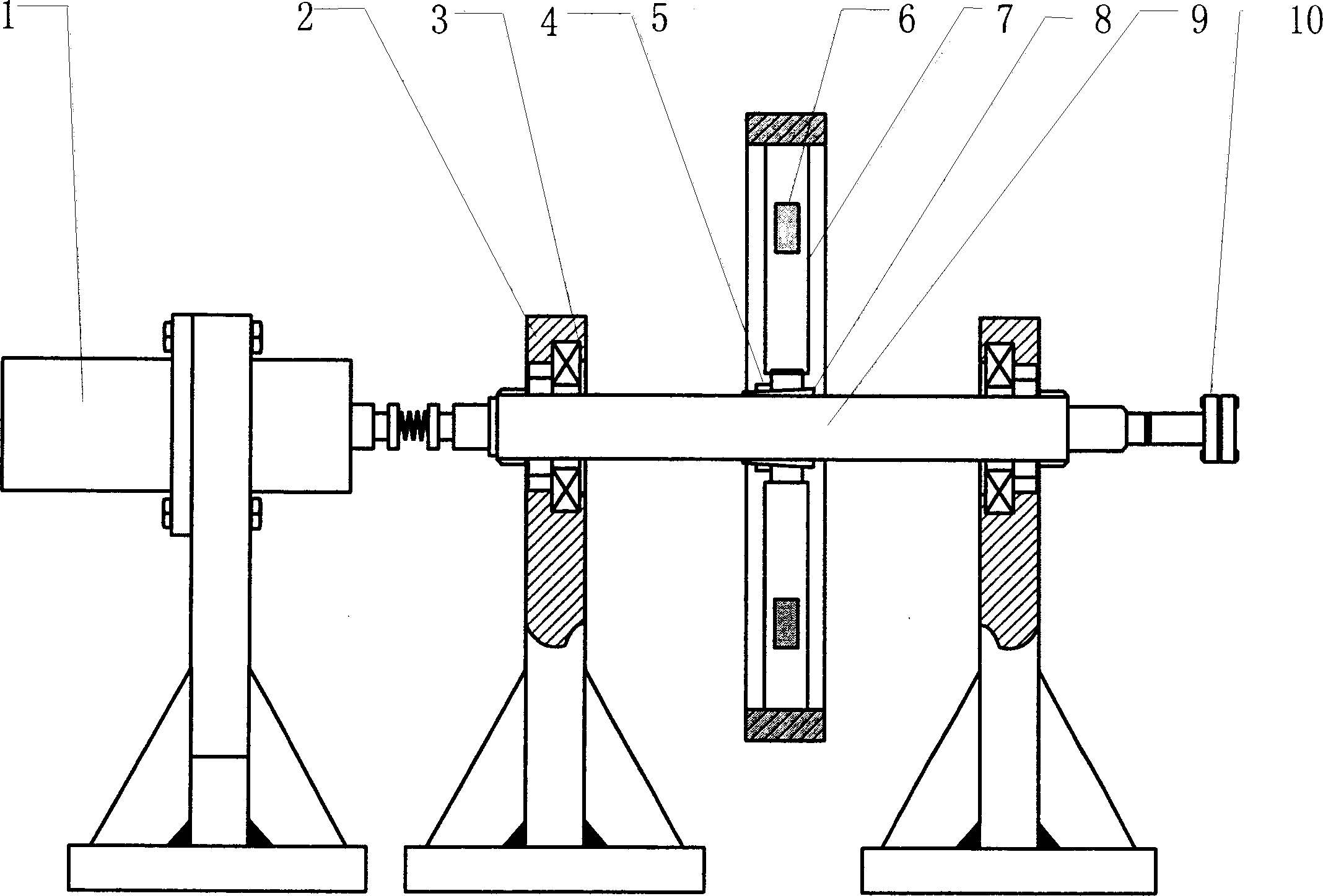

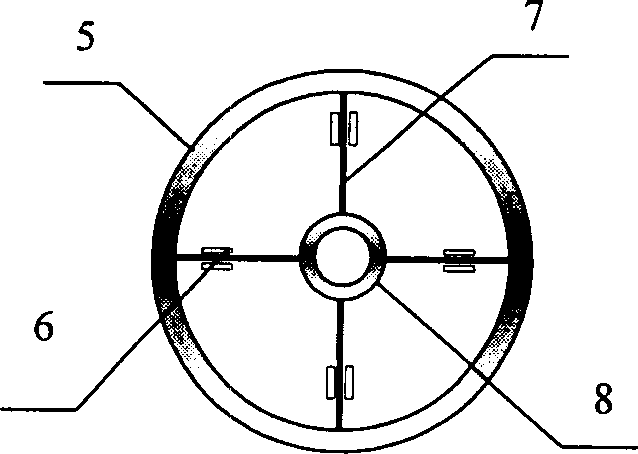

[0023] This embodiment proposes a method for measuring the torsional vibration of a rotary machine rotor and a device for implementing the method.

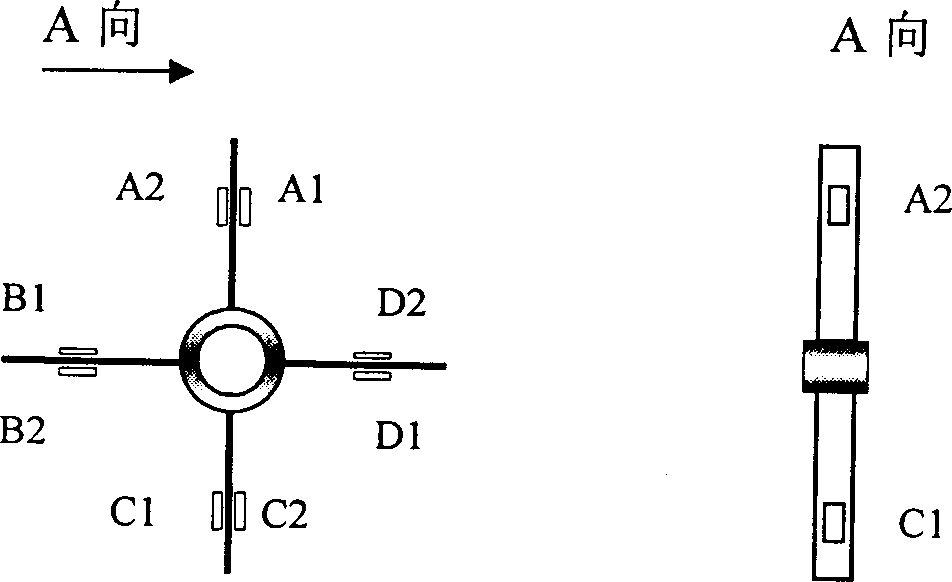

[0024] The technical solution adopted in this embodiment is to connect a measuring device that moves synchronously with the rotor, and through the elastic sheet 7 on the measuring device, the weak torsional vibration signal generated during the rotor movement is converted into a relatively large amplitude vibration signal. The strain signal is then extracted. Its principle is:

[0025] Let the torsional vibration amplitude of the rotor be = 0 cosΩt( 0 -Amplitude of rotor torsional vibration, Ω-frequency of rotor torsion); inertial ring torsional vibration amplitude is (ω-the natural frequency of the vibration system formed by the inertia ring and 4 elastic pieces, and ω = S I , I-moment of inertia of inertia ring, S-stiffness of ela...

Embodiment 2

[0038] This embodiment proposes a method for measuring the torsional vibration of a rotary machine rotor and a device for implementing the method.

[0039] The technical solution adopted in this embodiment is to connect a measuring device that moves synchronously with the rotor, and through the elastic sheet 7 on the measuring device, the weak torsional vibration signal generated during the rotor movement is converted into a relatively large amplitude vibration signal. The strain signal is then extracted. Its principle is:

[0040] Let the torsional vibration amplitude of the rotor be = 0 cosΩt( 0 -Amplitude of rotor torsional vibration, Ω-frequency of rotor torsion); inertial ring torsional vibration amplitude is (ω-the natural frequency of the vibration system formed by the inertia ring and 4 elastic pieces, and ω = S I , I-moment of inertia of inertia ring, S-stiffness of ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com