System for testing quality of cast in place concrete pile

A detection system and a technology for cast-in-place piles, which are applied to measurement devices, use sonic/ultrasonic/infrasonic waves to analyze solids, and use sonic/ultrasonic/infrasonic waves for material analysis, etc., and can solve problems such as low measurement efficiency, moving depth errors, and false anomalies. , to achieve the effect of improving quality inspection accuracy and measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

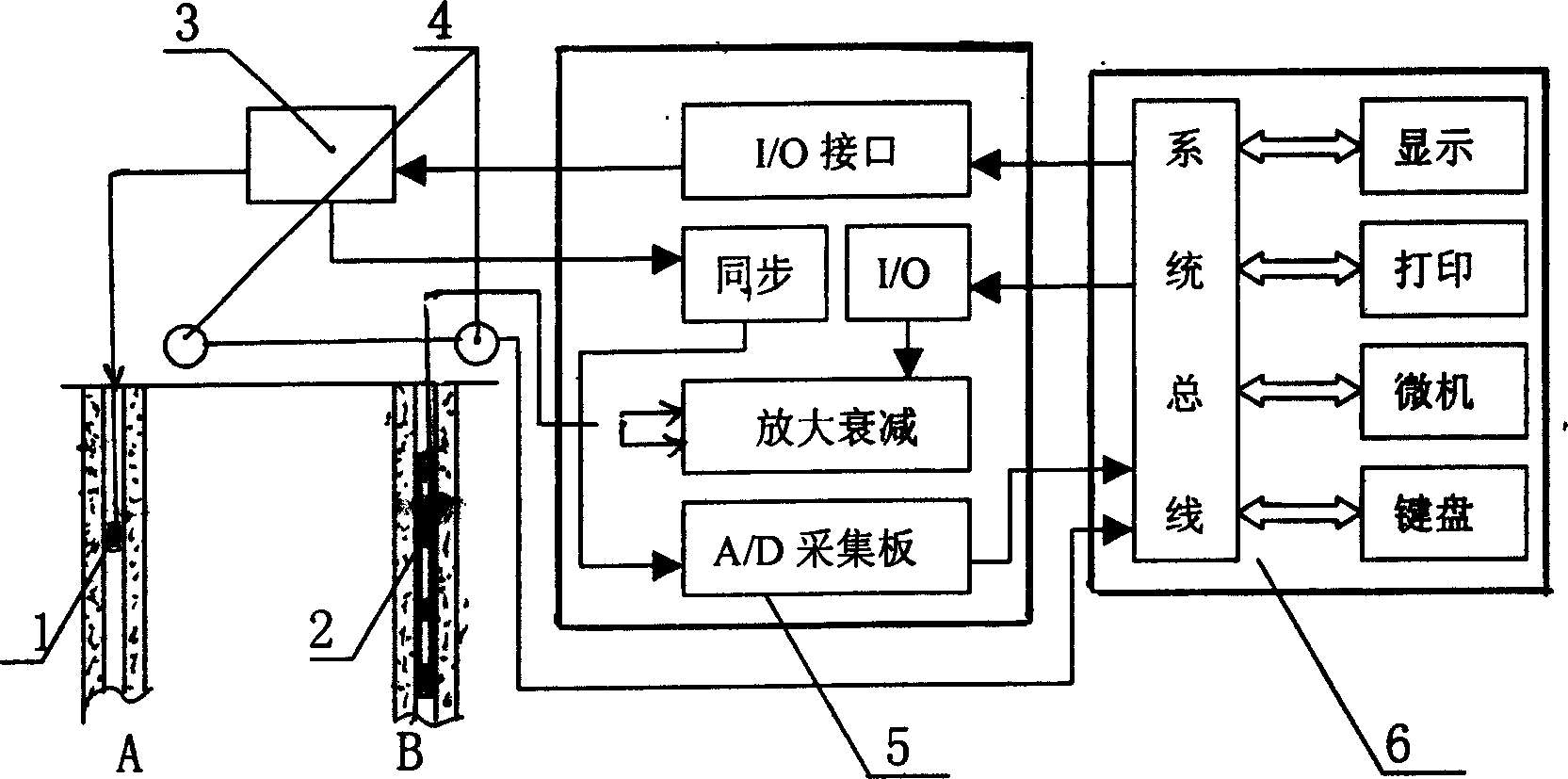

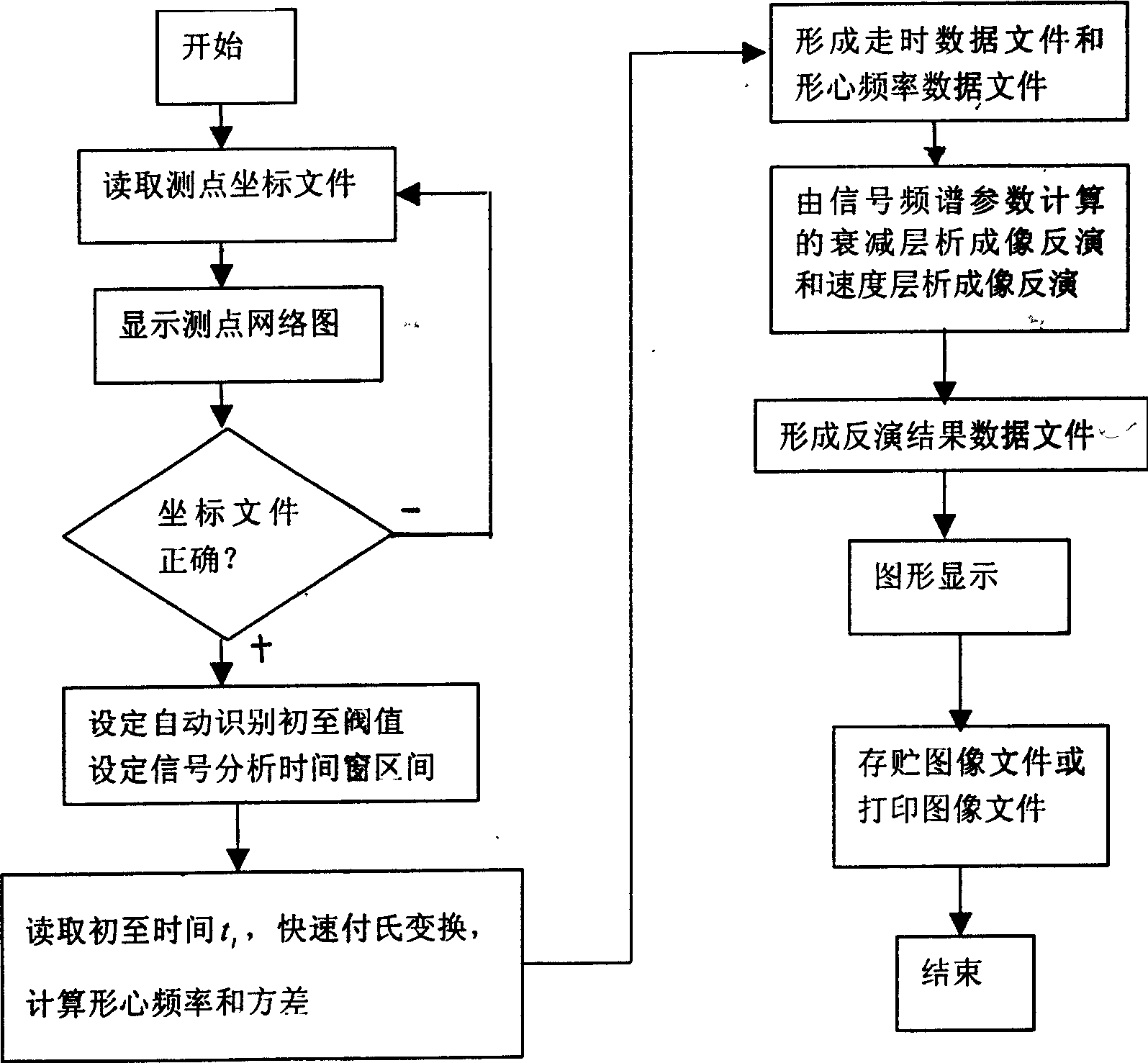

[0019] Refer to figure 1 , figure 2 , To explain the system composition and working principle process of the embodiment of the present invention.

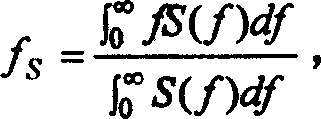

[0020] figure 1 Among them, the industrial microcomputer system 6 is used for data processing and display and printing of processing results. The ultrasonic transmitter 3 generates high-voltage pulses to excite the transmitter transducer 1 to generate ultrasonic waves. The ultrasonic transmitter transducer 1 is placed in the embedded pipe A of the concrete pile and radiates ultrasonic waves to the pile medium. In this embodiment, four receivers are used. The transducers are assembled in a tube shell with an interval of 10cm to form an ultrasonic transducer group 2, which is put into the embedded pipe B of another concrete pile with a rope to receive ultrasonic waves; and a depth encoder 4 controlled by a pulley is installed at the orifice, The coordinate file generated by the lifting depth coordinate of the transducer is stored in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com