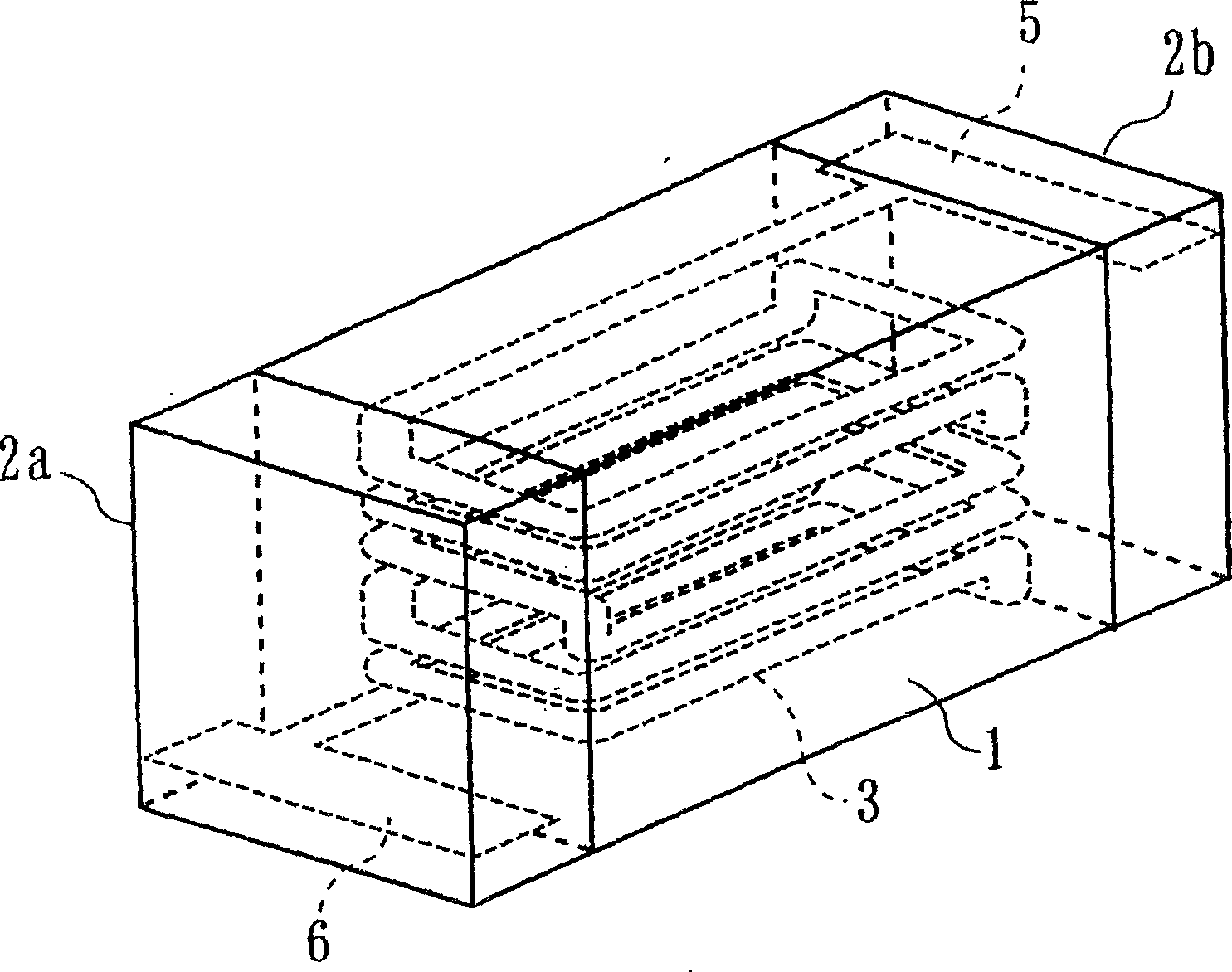

Method for manufacturing stratify electronic apparatus

An electronic device, laminated technology, applied in the direction of laminated capacitors, inductors/transformers/magnets, chemical instruments and methods, etc., can solve the problems of harmful effects of conductive particles, low reliability, easy intrusion into plating solutions and fluxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

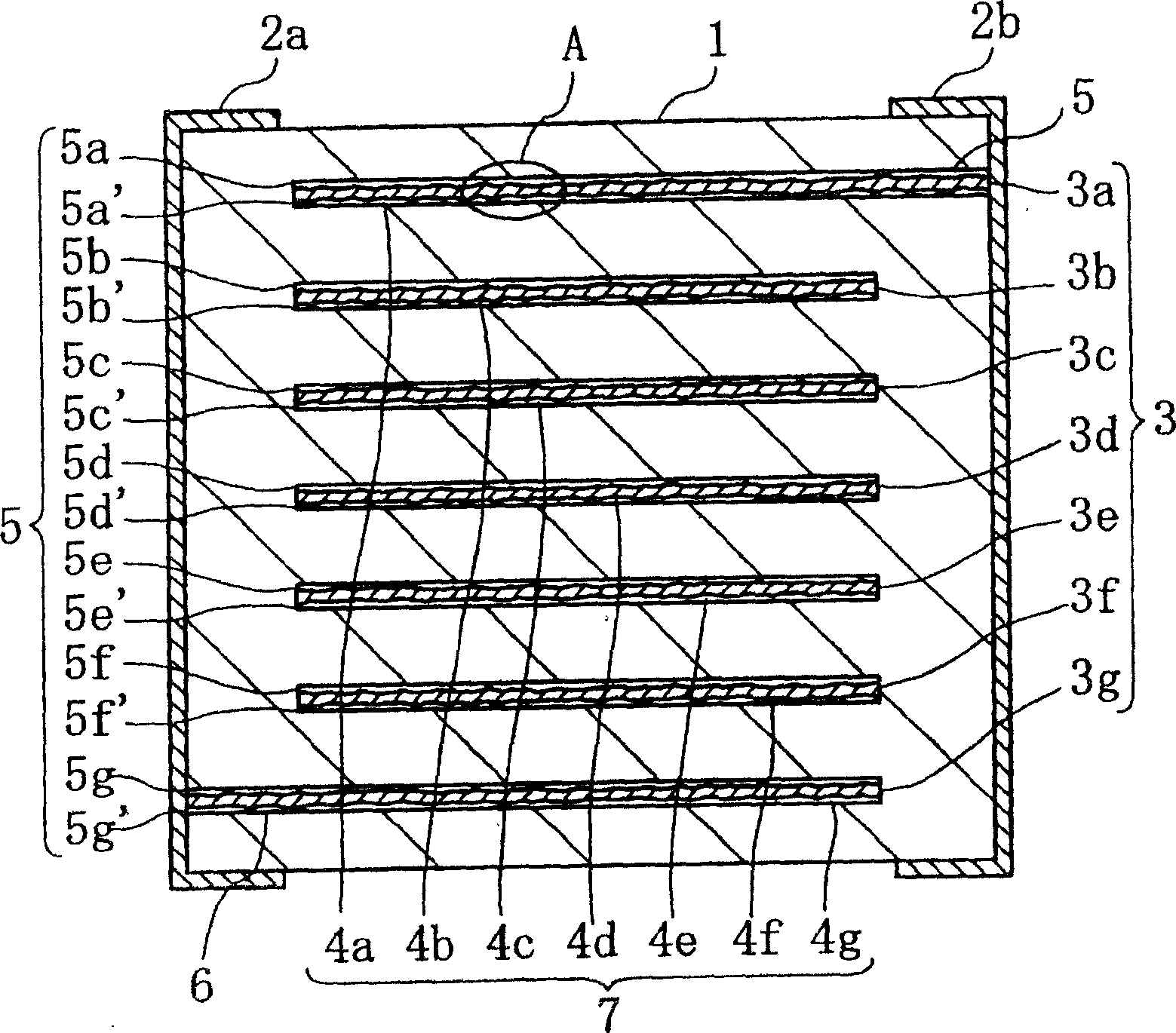

Method used

Image

Examples

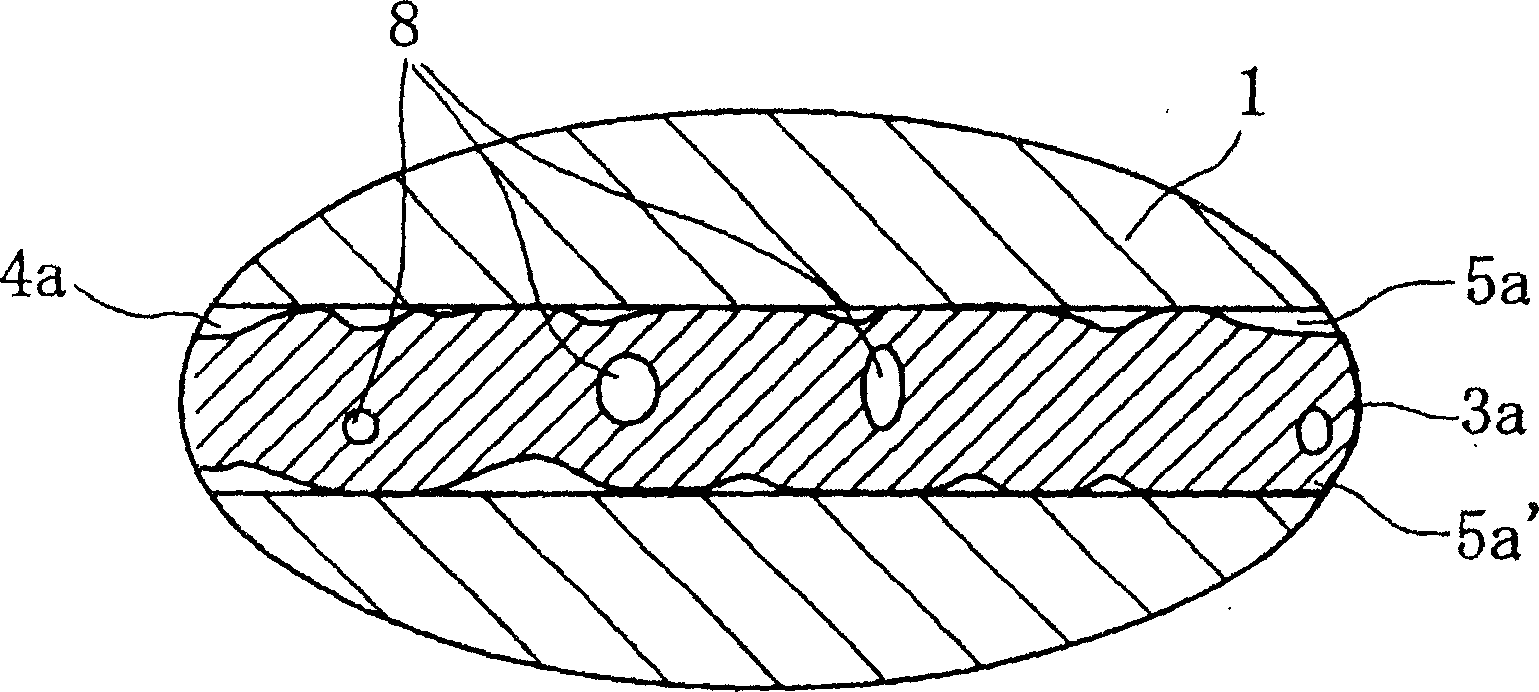

Embodiment 1

[0083] The inventors of the present invention firstly weighed NiO, CuO, ZnO, Fe 2 o 3 After waiting for the ferrite material, put these weighed objects into a ball mill with PSZ (partially stabilized zirconia) with a diameter of 1 mm as a dispersion medium for wet mixing and grinding to make a slurry powder, and the slurry After the powder was separated from PSZ, it was dried with a spray dryer, and calcined at 650° C. for 2 hours to prepare a calcined product.

[0084] Then, the calcined product is put into the above-mentioned ball mill for fully wet pulverization, dried by a spray drier to make a calcined powder.

[0085]Then add polyvinyl butyral as binder, dibutyl phthalate as plasticizer, ammonium polycarboxylate as dispersant and toluene as solvent to this calcined powder After mixing with ethanol, it is made into a ceramic slurry, and then the slurry is formed into a sheet by a knife coating method, etc., and a magnet sheet (uncalcined ceramic sheet) with a thickness ...

Embodiment 2

[0095] The multilayer inductor of Example 2 was produced in the same manner and procedure as in Example 1, except that the Ag particle content in the conductive paste was 20 volume %, and the resin particle content was 20 volume %.

Embodiment 3

[0097] The multilayer inductor of Example 3 was produced in the same manner and procedure as in Example 1, except that the Ag particle content in the conductive paste was 26 vol % and the resin particle content was 14 vol %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com