Gas cooling electric machine with pressure unit

A gas cooling and supercharging device technology, applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve problems such as susceptibility to interference, high cost, high expenditure on energy and input technology, and achieve automatic compensation for leakage losses, Improves the effect of absolute pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

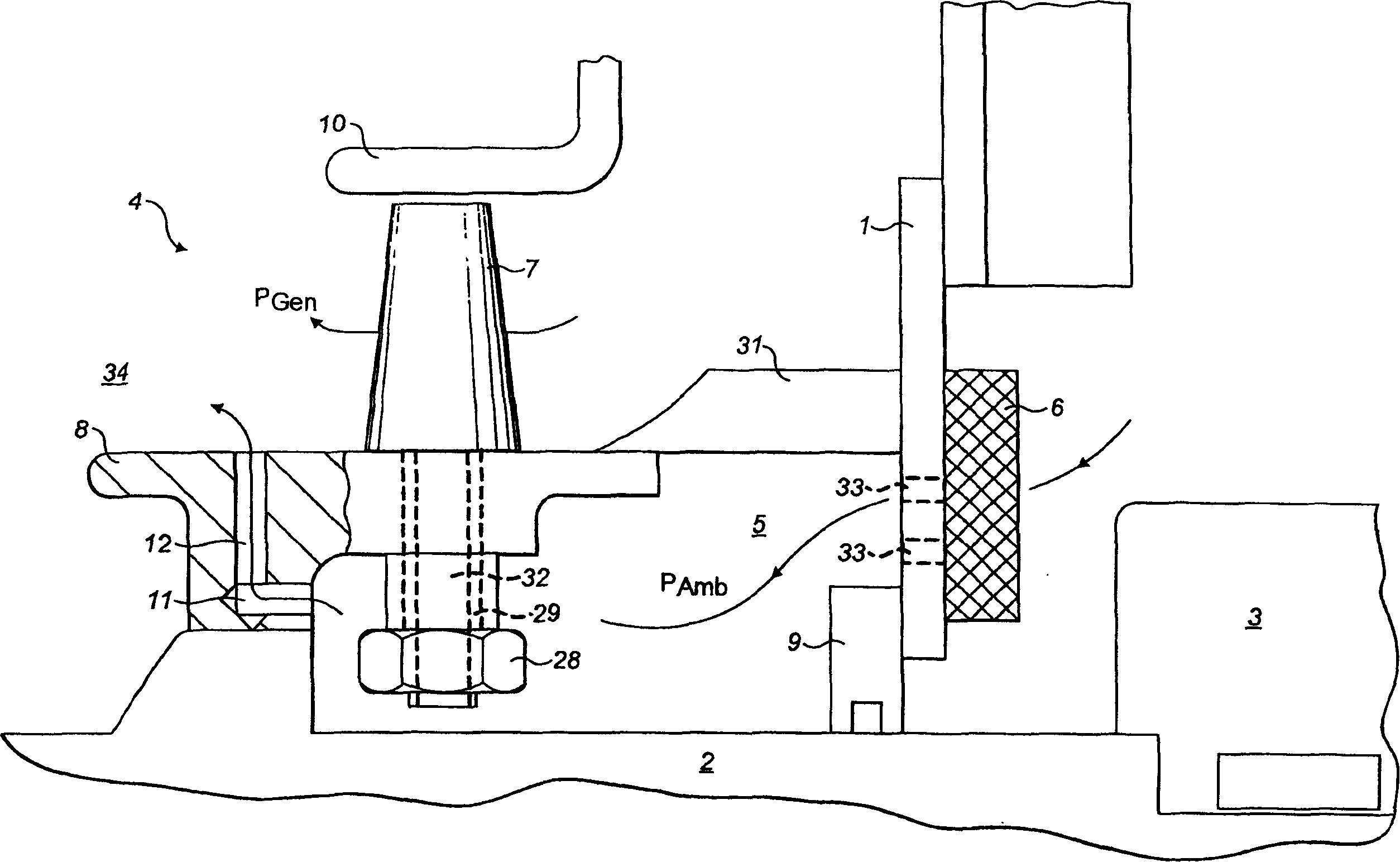

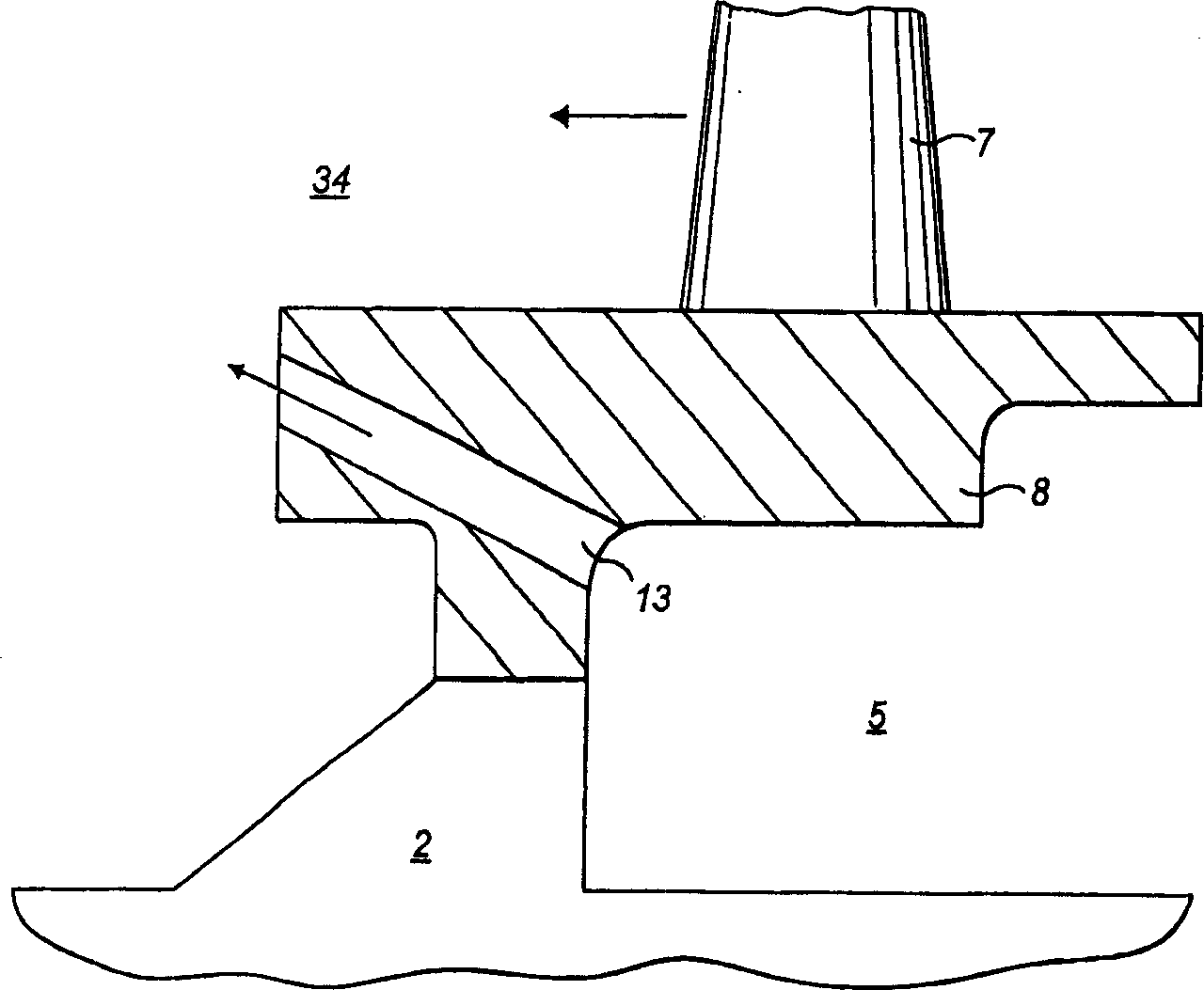

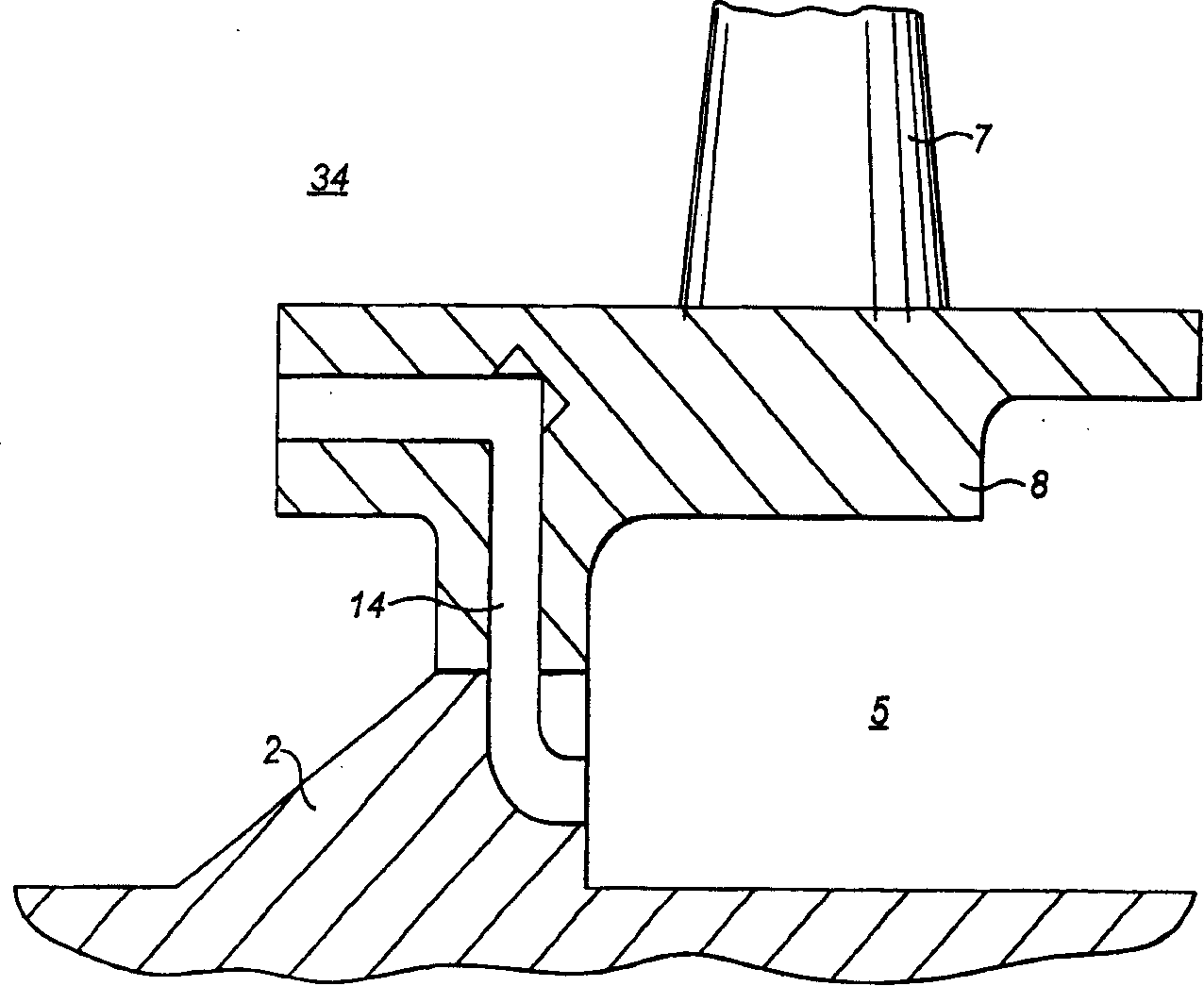

[0034] figure 1 The first embodiment showing the advantages of the supercharging device on the axial fan of the gas-cooled turbo-generator is shown, in which, figure 1 Only the components important to the supercharging device are schematically shown.

[0035]The turbine generator has a closed cooling circuit. As the cooling medium, air is preferably used. The flow direction of the circulating cooling medium is indicated by the streamline of the directional arrow in the drawing, and is basically distributed from right to left in the plane of the drawing. The turbo-generator has a partially illustrated generator casing 1 made of steel plate, which completely houses the generator itself (not shown) and the axial fan 4 for cooling medium circulation therein.

[0036] In this regard, the axial fan 4 is arranged on the rotor shaft 2, which is supported in bearings 3 on the outside of the generator casing 1. The shaft outlet is sealed from the outside through the shaft seal 9. The axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com