Open shutting structural member for concrete filling

A formwork component and a component technology are applied in the field of open formwork components for concrete filling, and can solve the problems of high cost and troublesome production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

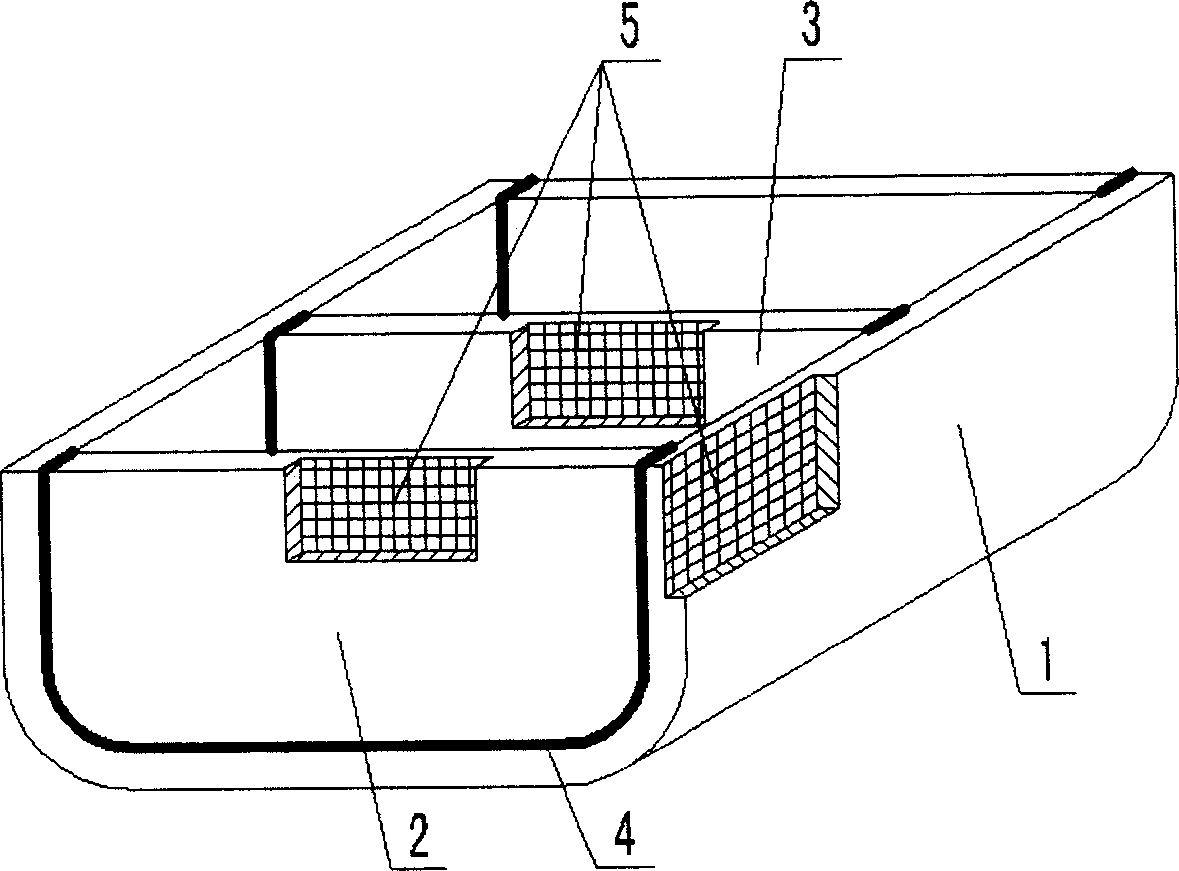

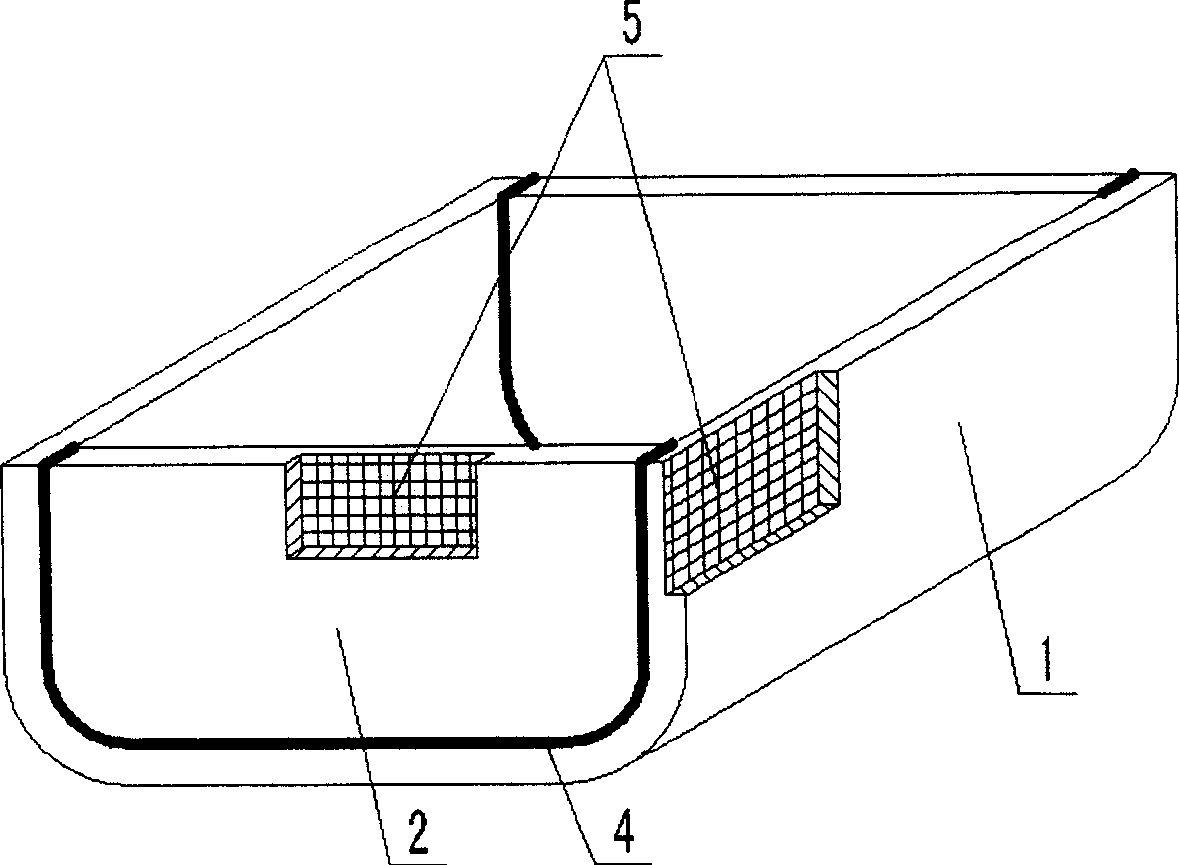

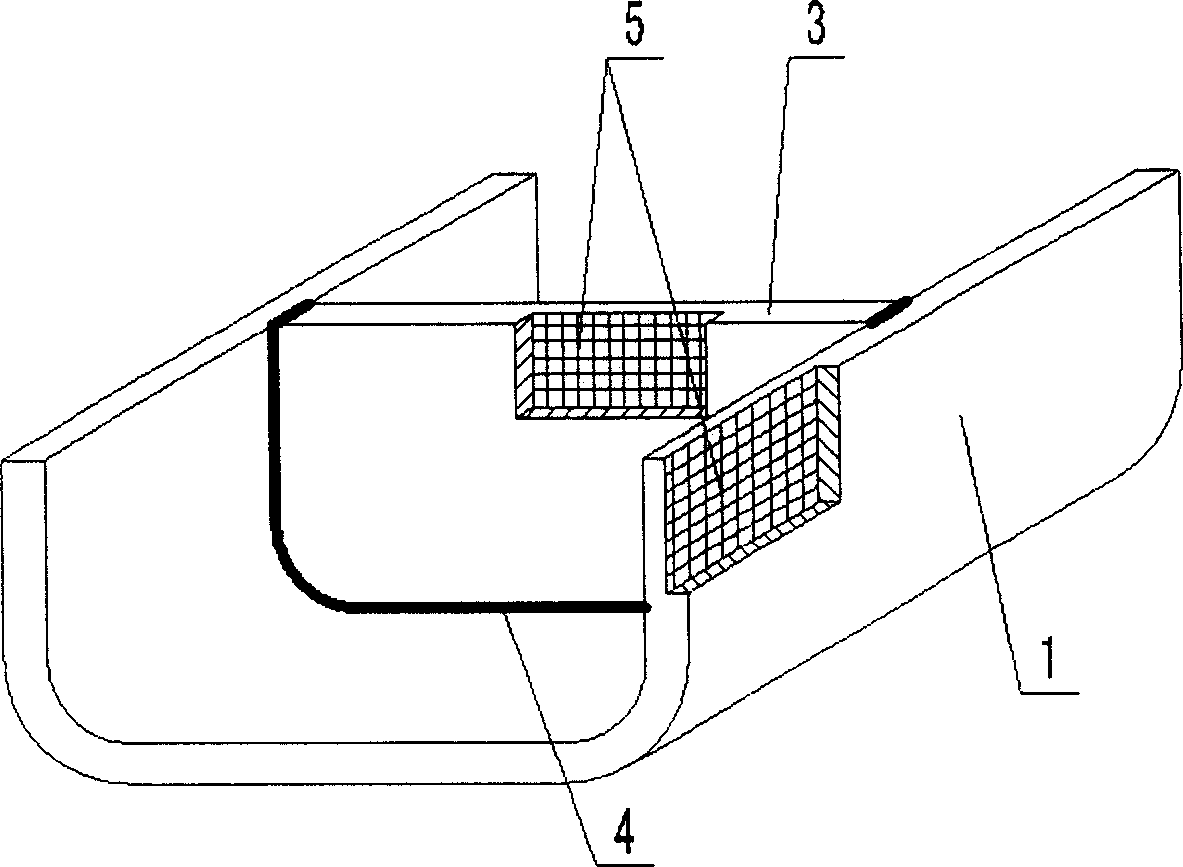

[0050] The present invention, as shown in the accompanying drawings, is characterized in that the formwork member is a U-shaped groove member, including a U-shaped groove 1, a prefabricated transverse groove end plate 2 or a prefabricated transverse groove middle plate 3, and the U-shaped groove 1 The bonding paste embryo body wraps the three side plate edges of the prefabricated transverse groove end plate 2 or the prefabricated transverse groove middle plate 3, and the embryo body and the prefabricated plate are bonded between the three side plate edges and the U-shaped groove 1 embryo body At least one of the joint seam 4, the U-shaped groove 1, the prefabricated transverse groove end plate 2 or the prefabricated transverse groove middle plate 3 contains a reinforcement 5. figure 1 It is a structural schematic diagram of Embodiment 1 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com