Motor driven tool such as a pole hedge trimmer with a locking mechanism for the turnable cutting unit

A technology of electric tools and locking mechanism, applied in cutting tools, cutting equipment, agricultural machinery and implements, etc., can solve the problems of easy detachment of the handle, no control of the cutting device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

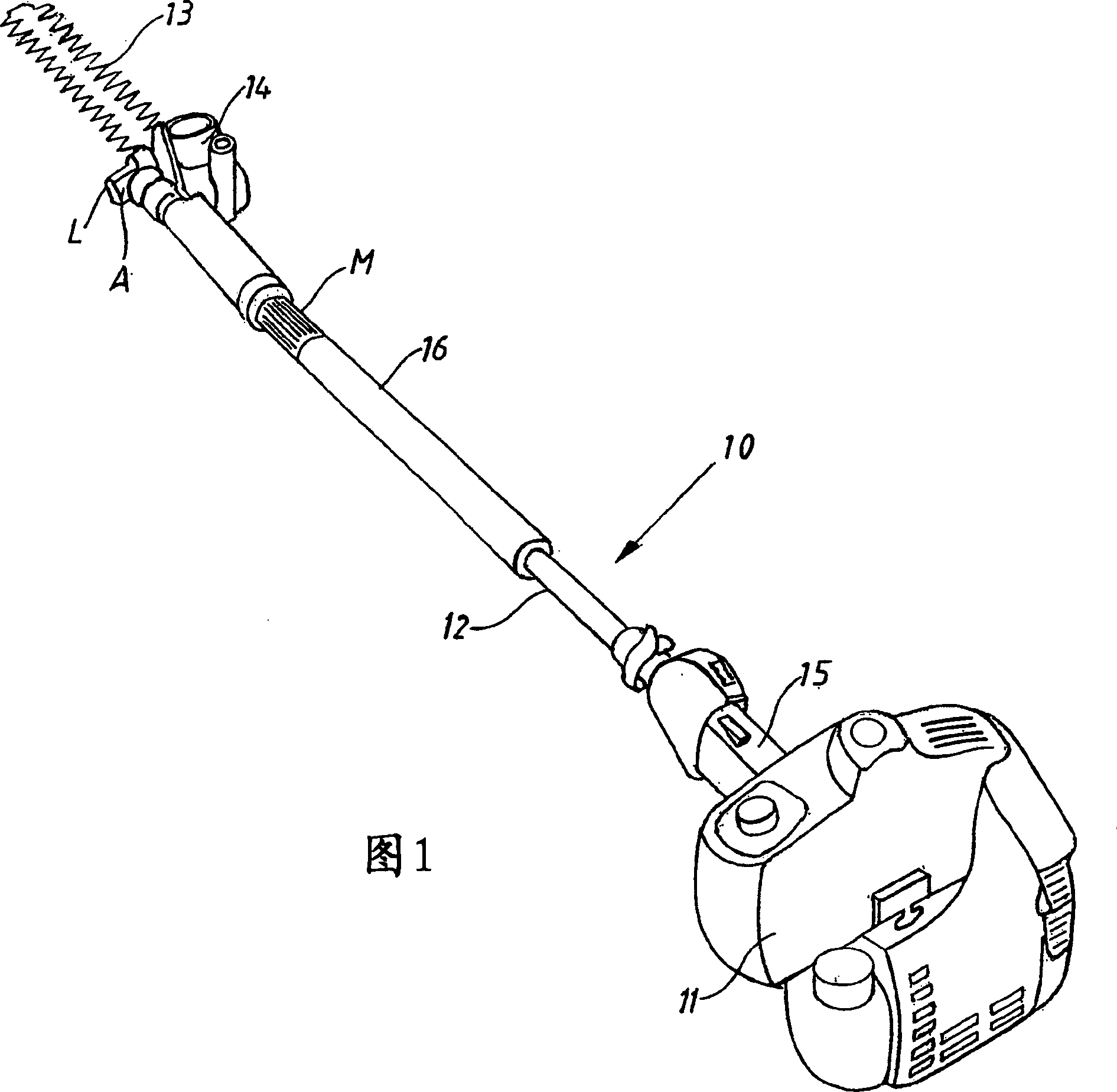

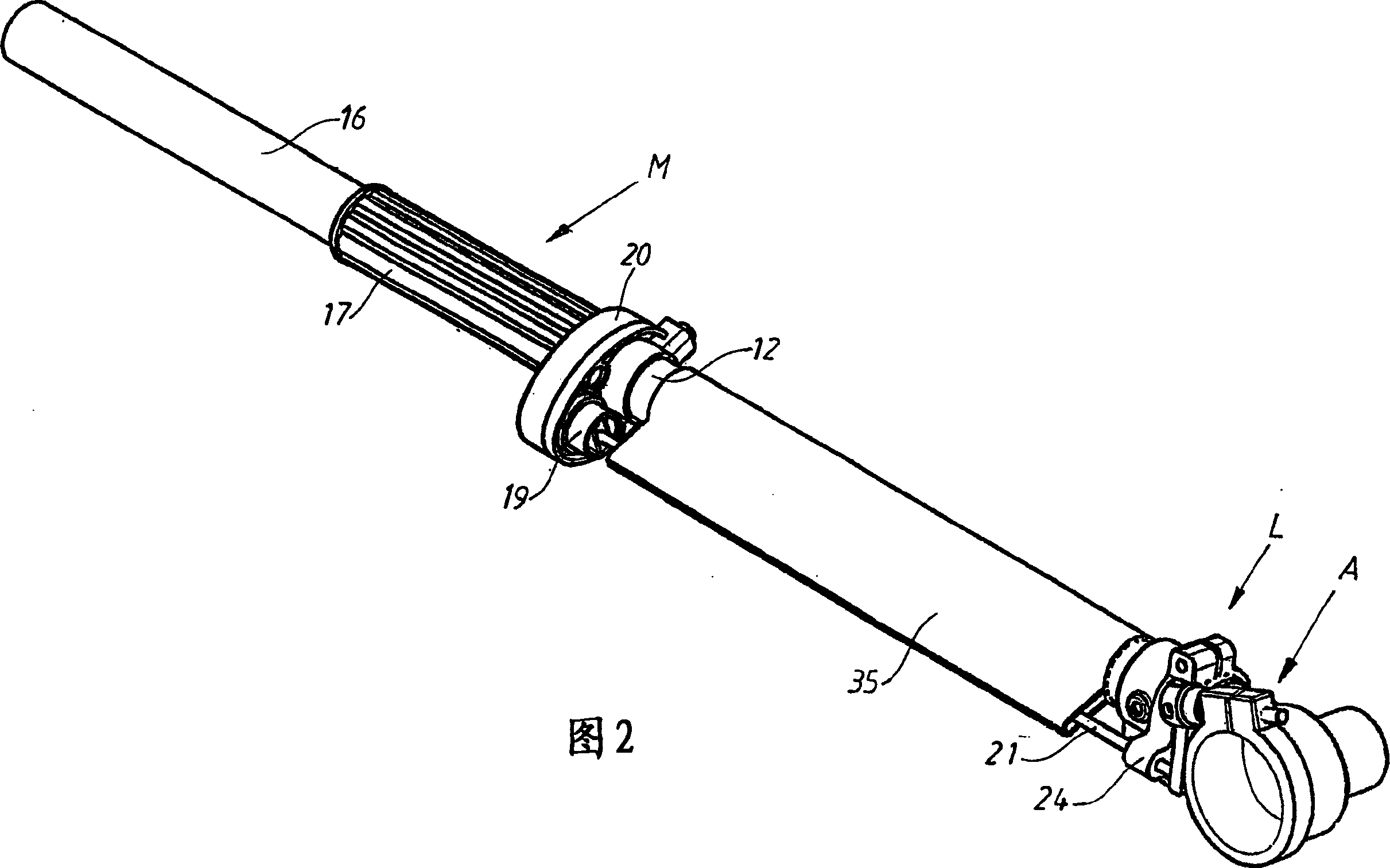

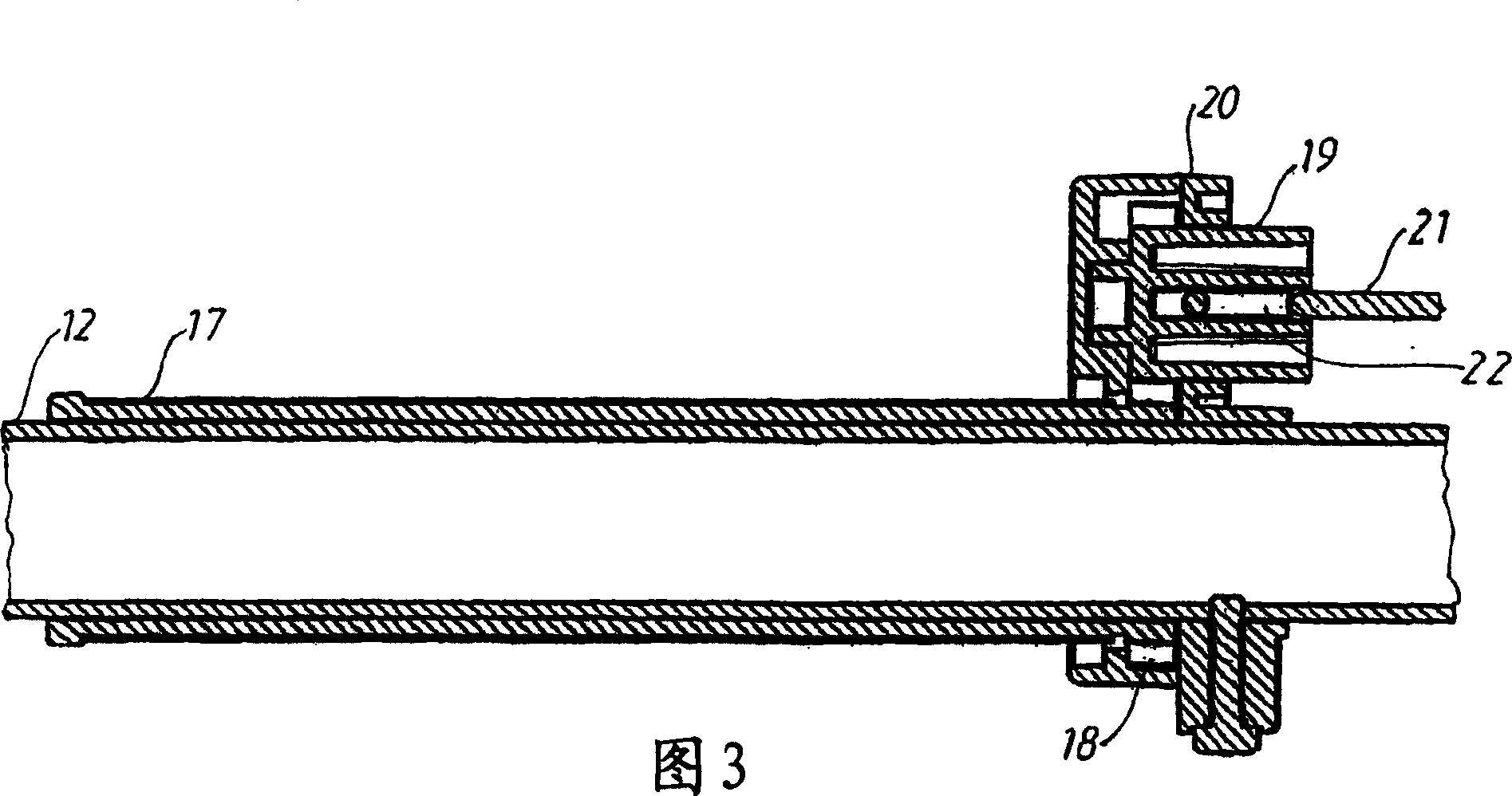

[0014] FIG. 1 shows that the pole hedge trimmer comprises a drive unit 11 connected via a shaft tube 12 to a cutting unit 13 . The driving device 11 can be in various forms, such as an internal combustion engine or an electric motor, the output shaft of which is connected to a drive shaft (not shown), which is arranged in the shaft tube and connected with the cutting device through a gear 14 . The shaft tube 12 has an inner handle 15 and an outer handle 16, the inner handle 15 has a valve (throttle) control device for the driving device and additional control devices, and the outer handle 16 is designed as a sleeve made of a material that is easy to grip. In a conventional manner, the cutting device 13 has a fixed comb-shaped cutter head protector to cooperate with the corresponding cutter head, wherein the cutter head is driven by the drive shaft through the gear 14 and moves back and forth. The cutting device 13 is supported by the shaft tube 12 via a rotatable connection A....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com