Flue gas desulfurization apparatus, flue gas desulfurizationsystem, and method for operating flue gas desulfurization apparatus

A desulfurization device and desulfurization equipment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large-scale concentration equipment and increased cost of sulfuric acid manufacturing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to explain this invention in detail, it demonstrates based on drawing.

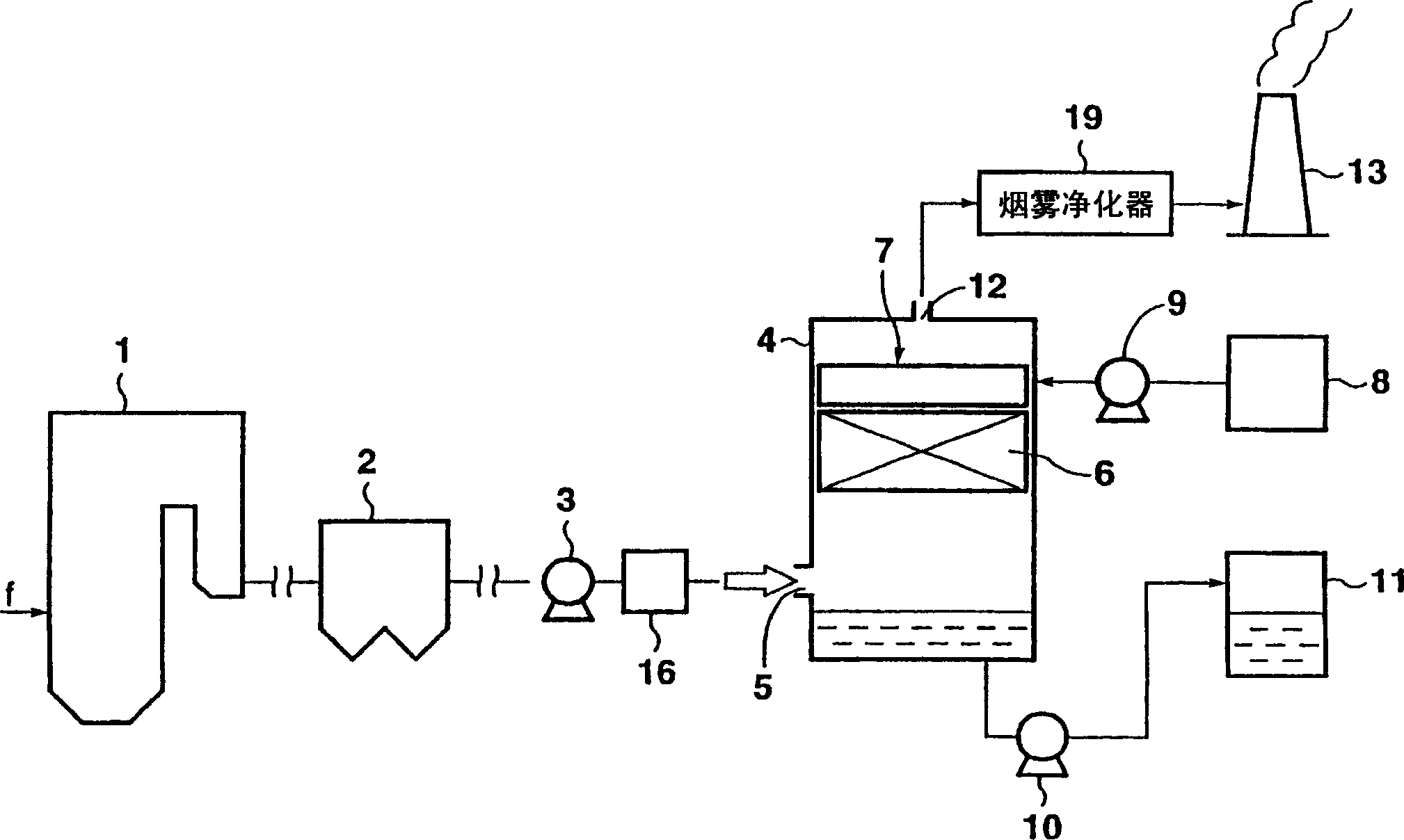

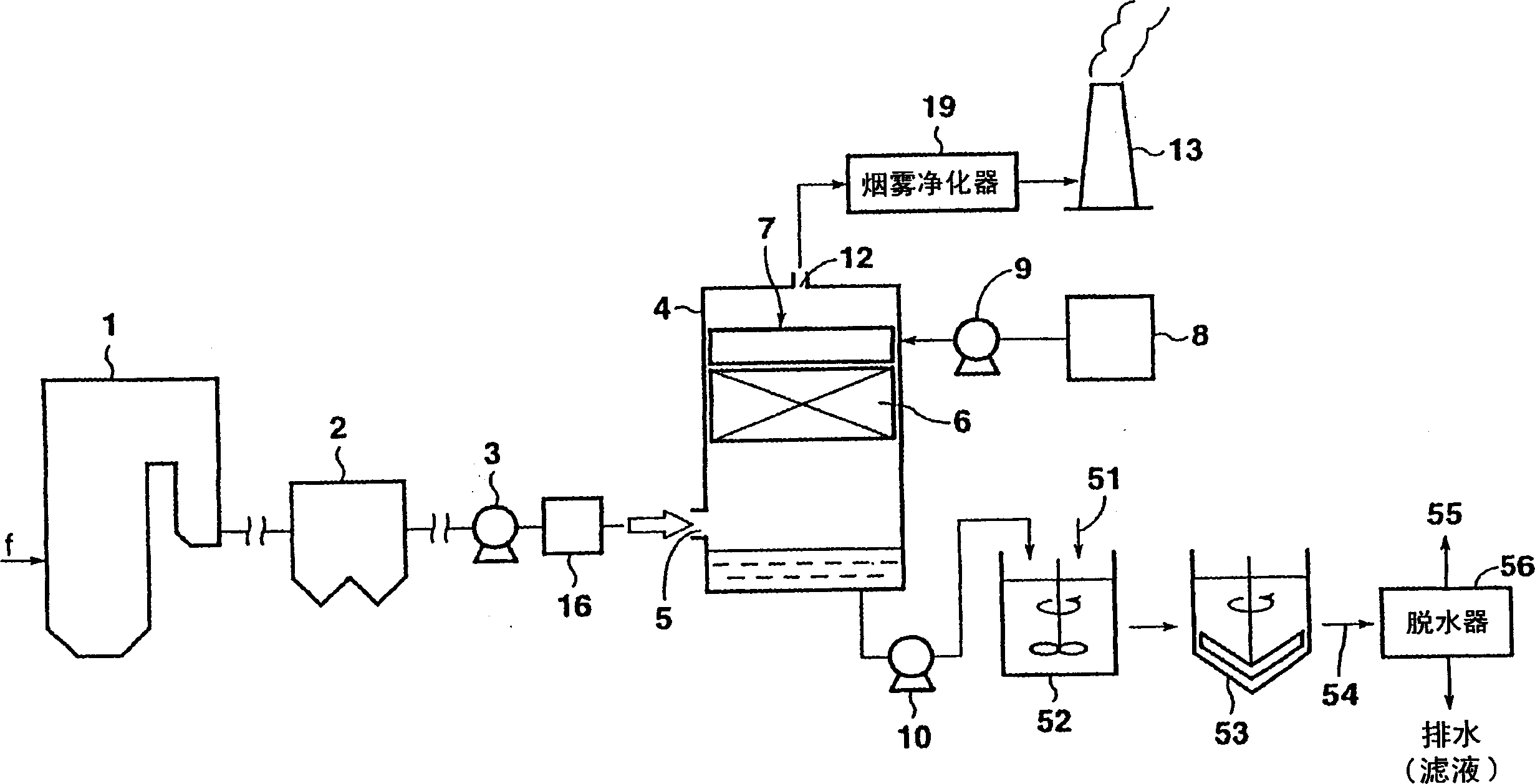

[0084] according to figure 1 An exhaust gas treatment system including the exhaust gas desulfurization device of Example 1 will be described.

[0085] Such as figure 1 As shown, for example, fuel f such as coal and heavy oil is burned in boiler 1 that generates steam in order to drive a steam turbine of an unshown thermal power plant. The exhaust gas from boiler 1 contains sulfur oxides (SO X ), the exhaust gas is denitrified by a denitrification device not shown in the figure, and after being cooled by the exhaust gas heater, dust is removed in the dust collector 2.

[0086] The dedusted exhaust gas is sent to the humidification cooling device 16 through the blower 3, and water (containing dilute sulfuric acid) is mixed in the humidification cooling device 16 to become the exhaust gas in a saturated steam state. At this time, smoke may be contained in the exhaust gas. The exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com