End plug type ball screw rod with lubricating mechanism

A lubricating mechanism and ball screw technology, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of lubricating oil waste, uneven lubrication, and lengthening of nuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

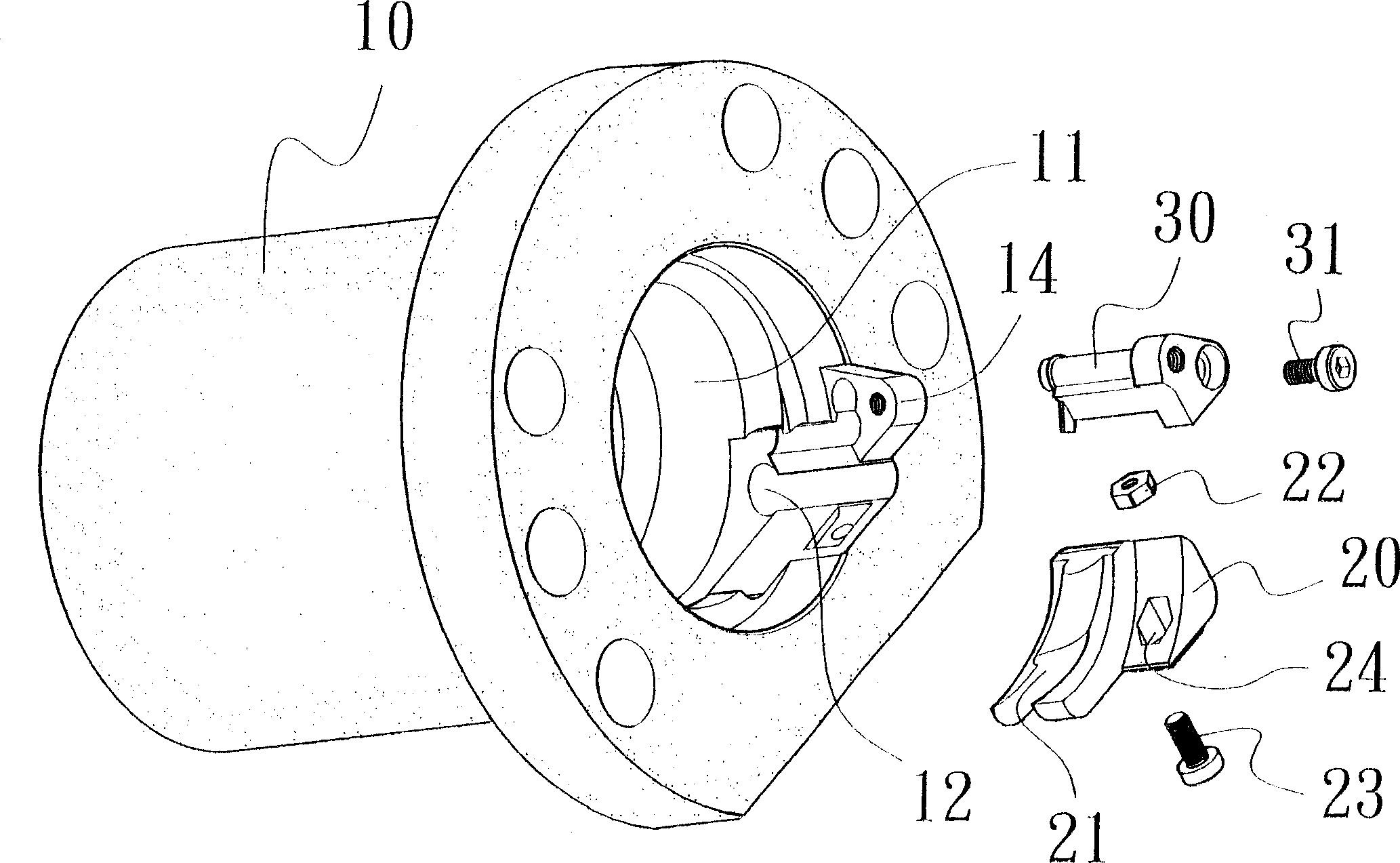

[0025] figure 1 It is a three-dimensional exploded view of an end-plug ball screw with a lubrication mechanism of the present invention; wherein the return device 20 of the present invention is arranged on the inner side of the end surface of the nut 10, and the return device 20 is provided with a turning path 21 to connect the surface of the inner diameter of the nut 10 The return channel 12 between the rolling groove 11 and the inner and outer diameters, and the return device 20 is also provided with a bolt hole 24 for the installation of the bolt 23 and the lock nut 22, so that the return device 20 is fixed on the inner side of the end surface of the nut 10. And a lubricating groove 14 is provided on the inner side of the end surface of the nut 10 adjacent to the return device 20 , for the lubricating mechanism 30 to be installed therein and locked on the inner side of the end surface of the nut 10 by the fixing bolt 31 .

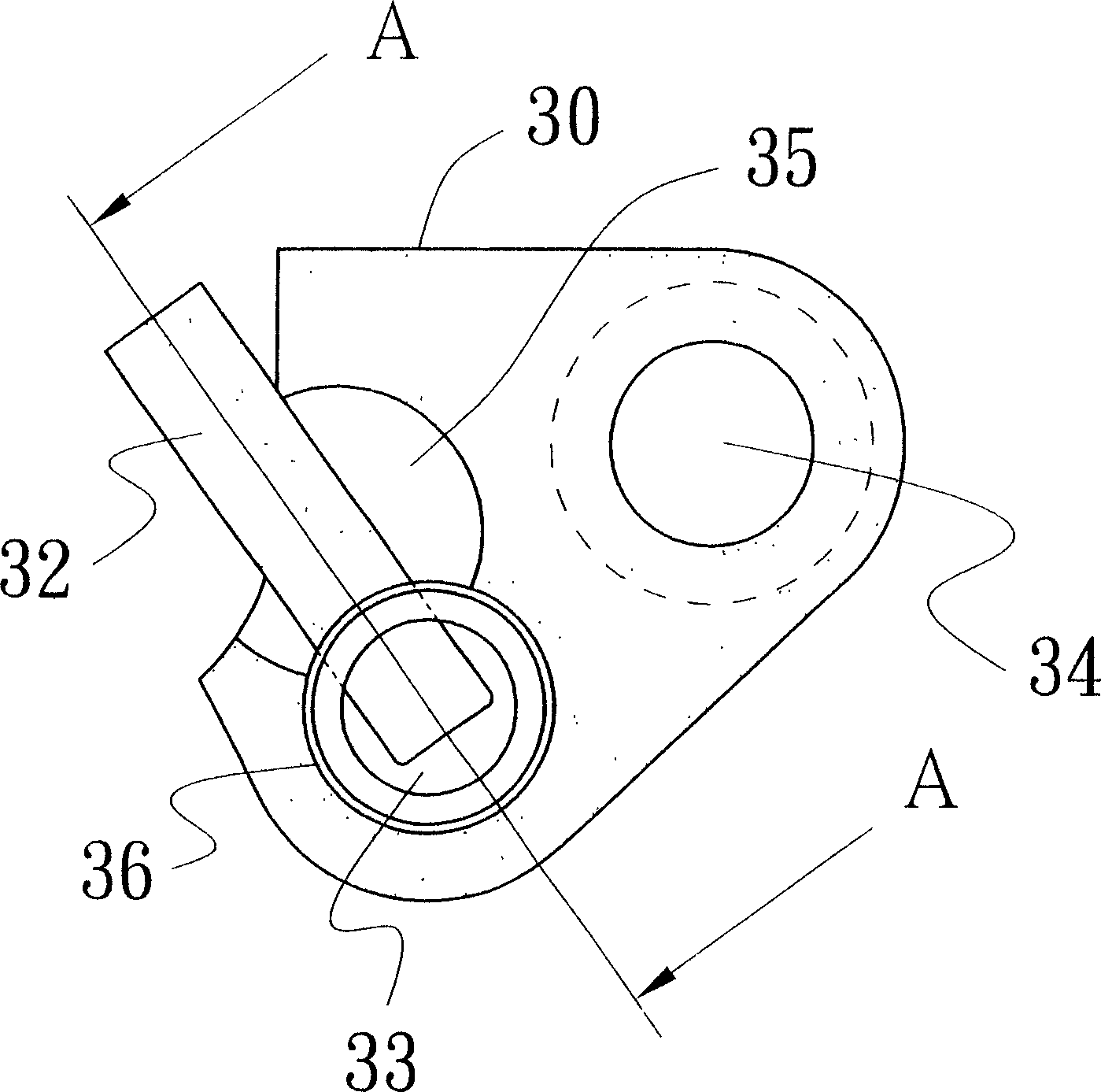

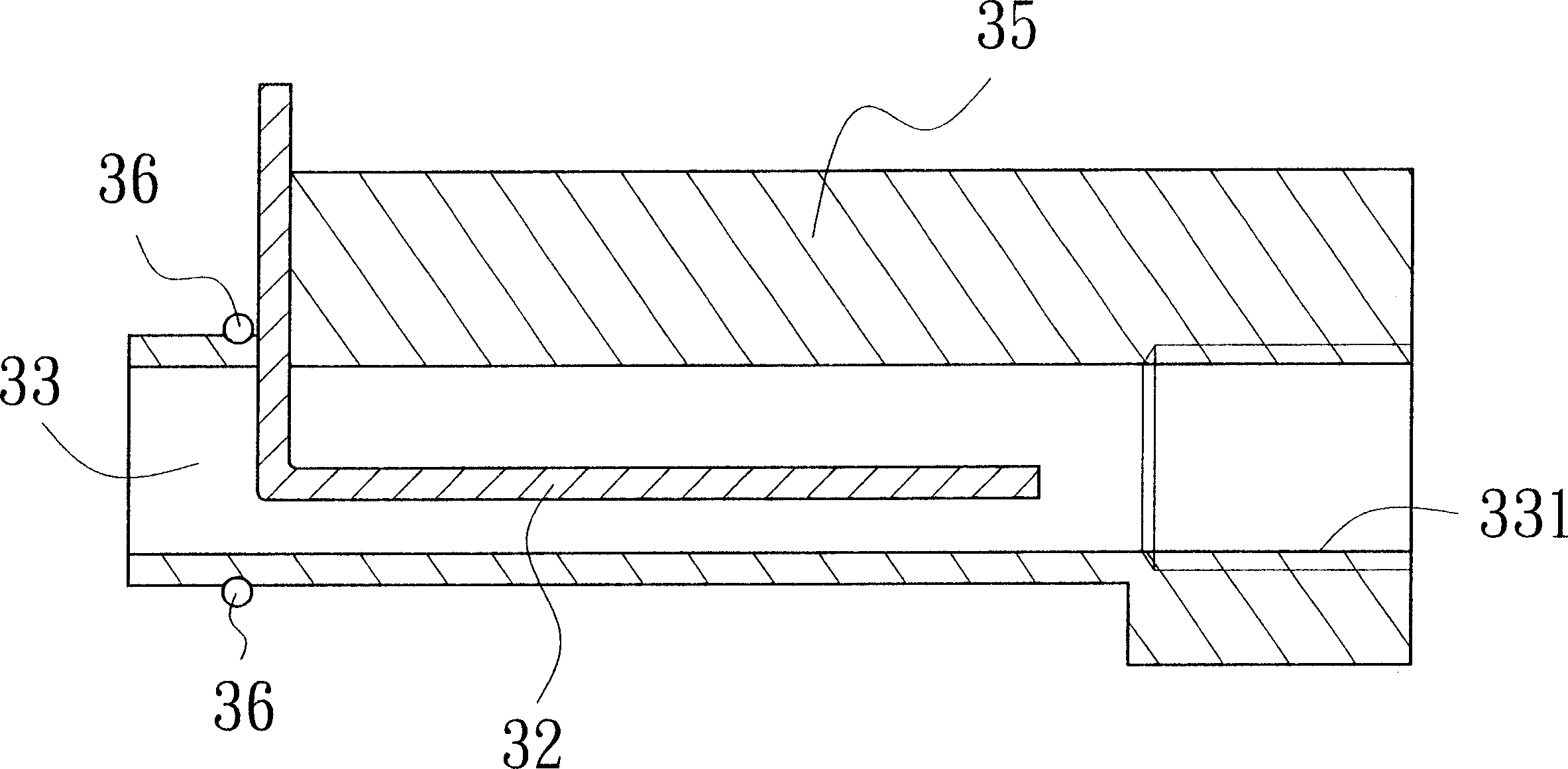

[0026] figure 2 for figure 1 Top view of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com